Construction Material All Type Color Coated Galvanized Steel /PPGL Steel roofing Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction Material All Type Color Coated Galvanized Steel /PPGL Steel Roofing Sheets

1. Detailed Specifications:

| Product | PPGI Color Coated Galvanized Steel Sheet/Coloful Steel Coil |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Construction Material All Type Color Coated Galvanized Steel /PPGL Steel Roofing Sheets

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

.Manufacture anticorrosion, industrial and roof boarding,roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils.

.Corrosion resistant parts of cars.

.Food storage, meat and aquatic products’ freezing and processing equipment.

.The equipments to store and transport materials, and packing implements.

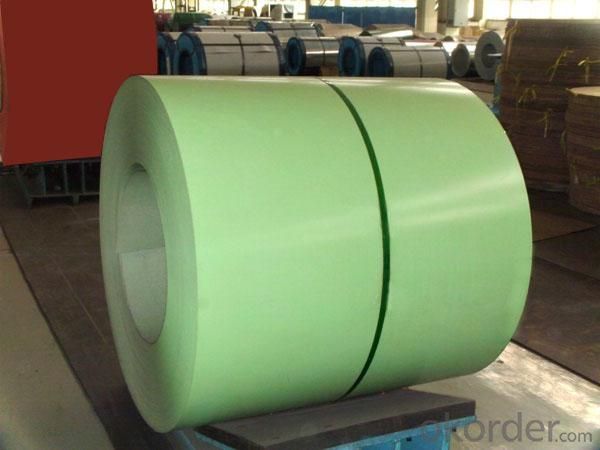

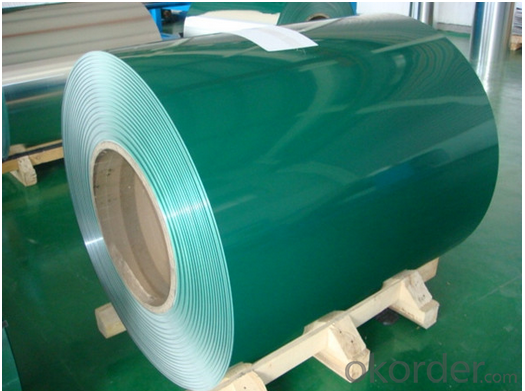

3. Construction Material All Type Color Coated Galvanized Steel /PPGL Steel Roofing Sheets Images:

production Line:

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the applications of steel coils?

- Steel coils are utilized across a wide array of industries due to their versatility and durability. The construction industry, in particular, heavily relies on steel coils for structural purposes. These coils can be shaped and molded into different sizes and forms to create essential components like beams, columns, and other structural elements needed in buildings, bridges, and infrastructure projects. Another significant field that benefits from steel coils is the automobile manufacturing industry. Steel coils are instrumental in producing various parts and components of vehicles, including body panels, chassis, frames, and engine parts. The exceptional strength and durability of steel make it an ideal material for ensuring the safety and longevity of automobiles. Moreover, steel coils play a crucial role in the production of household appliances such as refrigerators, washing machines, and stoves. Steel's versatility allows it to be easily molded and shaped into different configurations, making it suitable for various appliance components. In the energy sector, steel coils find extensive use in the manufacturing of power generation equipment and pipelines. Turbines, generators, and other equipment used in power plants are made from steel coils. Additionally, steel coils are employed in constructing pipelines for the transportation of oil, gas, and other fluids. Furthermore, steel coils are widely employed in the fabrication of storage tanks, industrial machinery, and agricultural equipment. They are also utilized in the production of furniture, shelving units, and various metal products. In summary, steel coils play a vital role in numerous industries, including construction, automotive, appliance manufacturing, energy, and others. The strength, durability, and versatility of steel make it an indispensable material for both structural and functional purposes.

- Q: How are steel coils used in the production of metal containers?

- Steel coils are used in the production of metal containers by being processed and formed into sheets, which are then shaped and welded to create the body and lids of the containers. The strength and durability of steel make it an ideal material for these containers, providing protection for goods during transportation and storage.

- Q: is stainless steel a good steel for sensitive skin? or does it have to be surgical or sterling silver?

- I have sensitvie skin also. I use nickel free and titanium jewlrey, they're the safest. I never used surgical steel before though.

- Q: How are steel coils inspected for thickness variations?

- Steel coils are inspected for thickness variations using non-destructive testing methods, such as ultrasonic or electromagnetic techniques. These methods involve the use of specialized equipment that can measure the thickness of the steel coil at various points, ensuring that it meets the required specifications.

- Q: What are the different methods of galvanizing steel coils?

- There are several methods of galvanizing steel coils, including hot-dip galvanizing, electro-galvanizing, and continuous galvanizing.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using specialized equipment such as cranes or forklifts. During the loading process, the coils are carefully lifted and secured onto the ship's deck or into designated storage areas using slings or clamps. To ensure stability and prevent damage, proper balancing and securing techniques are employed. Unloading follows a similar procedure, with the coils being carefully lifted from the ship using the appropriate equipment and then transferred to trucks or storage facilities for further transportation or distribution.

- Q: What are the common coil processing methods?

- Some common coil processing methods include slitting, shearing, blanking, leveling, and edging.

- Q: I have two guitars, a nylon stringed classical, and a steel stringed acoustic, I find the nylon strings easier to play, but doesn't have as good of sound as the steel stringed, and when I play with the steel strings, it really hurts my fingers, and if I play just a little bit, it feels like the high e string is going to cut my finger. Are the strings too high? What can I do to make the steel strings easier to play?

- Your steel-string acoustic should not be all that much harder to play than your nylon string acoustic. Classical guitars have stretchier strings, but they also normally have higher action (string height). It sounds like your steel-string may have a problem. A typical low action would be around 0.090 gap between the low E string and the top of the 12th fret, and 0.070 between the high E and the top of the 12th fret. If yours is a lot higher than that, having it professionally set up will probably help. If it's a very cheap guitar, replacement might be the best option. Why do you need to choose between classical and steel-string? You already own both.

- Q: So we all know a 1000lb steel ball will sink in water, but if you were to leave the center of the ball hollow and fill with air, if the steel ball was big enough in diameter it should float correct? What size would the steel ball need to be to float?

- specific gravity of a steel is approximately 7.82 as compared to water. so, the hollow sphere(filled with air) is having volume more by 7.82 as compared to solid sphere, then the 1000 lb hollow steel ball float in the water (Why Do Ships Float? The Greek Mathematician and inventor Archimedes lived during the 3rd century BC. According to history he was in the bath one day when he discovered the principle of buoyancy which is the reason why huge Greek ships weighing thousands of pounds could float on water. He noticed that as he lowered himself into the bath, the water displaced by his body overflowed the sides and he realised that there was a relationship between his weight and the volume of water displaced. It is said that he ran naked into the street yelling heurEka which is where we get our word eureka! (I found it), Greek heurEka I have found, from heuriskein to find. The Buoyancy Principle: Archimedes continued to do more experiments and came up with a buoyancy principle, that a ship will float when the weight of the water it displaces equals the weight of the ship and anything will float if it is shaped to displace its own weight of water before it reaches the point where it will submerge. This is kind of a technical way of looking at it. A ship that is launched sinks into the sea until the weight of the water it displaces is equal to its own weight. As the ship is loaded, it sinks deeper, displacing more water, and so the magnitude of the buoyant force continuously matches the weight of the ship and its cargo.)

- Q: 1943 steel pennies

- You really don't want to do anything to to them. If they're rusty, that's just the way they are now. Store them in a dry place. Cleaning will do more damage than good, and will hurt the value. If it were possible to undo the damage, our cars would never rust, iron pipes wouldn't pit, and everything would be made of steel. Don't let it worry you, they're still worth having.

Send your message to us

Construction Material All Type Color Coated Galvanized Steel /PPGL Steel roofing Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords