Construction Galvanized Steel Kwikstage Scaffolding System with High Quality CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Construction Galvanized Steel Kwikstage Scaffolding System with High Quality

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Brand Name:

Surface:

Material.:

Thickness:

Descriptions of Construction Galvanized Steel Kwikstage Scaffolding System with High Quality

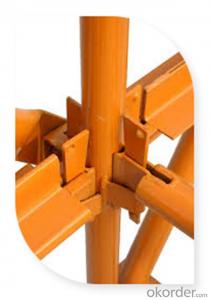

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

The Accessories of Construction Galvanized Steel Kwikstage Scaffolding System with High Quality

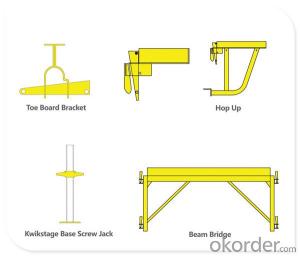

Kwikstage Products: Standard; Ledgers; Transom; Steel Plank; Hop Ups; Diagonal Braces; Tie Bars; Toe board Brackets; End Toe Board Brackets; Double C Clip; External Cup Standard

Props and Formwork: Formwork Prop; Formwork Jacks ; Shoring Jacks

Other Accessories: Ladder Beams; Aluminium Stair ; Base Jack; Swivel Jack ; Steel Pallet; Steel Mesh Pallet.A)Kwikstage Standard

Length: 3.0m;2.5m;2.0m;1.5m;1.0m;0.5m Thickness: 4mm Surface: Painted or Hot Dipped Galvanized Certificate: AS / NZS 1576.3-1995 B) Kwikstage Ledgers

Surface painted or hot dipped galvanized Thickness 3.2mm; 3mm Length 2.4m; 1.8m; 1.2m; 0.7m Certificate AS / NZS 1576.3-1995 C) Kwikstage Transom

Surface painted or hot dipped galvanized Thickness 5mm Length 2.4m;1.8m;1.2m;1.0m;0.7m D)Kwikstage Scaffolding Steel Board / Steel Plank

Length 2.4m ; 1.8m; 1.2m; 0.7m Thickness 1.8mm galv.iron sheet Certificate AS 1577-1993 FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Erection of scaffolding accessories

- Erection of scaffolding accessories:Door frame should be installed from one end to the other end of the extension, and layer by layer to change the direction of the set, not the opposite. After the completion of one step, should check and adjust its level and verticality. Scaffolding should be built around the building, continuous, synchronous erection elevation, in the form of a closed structure around the building; if not closed, the scaffold should be added at both ends of the wall.

- Q: I'm gonna be getting piercings this weekend, so i know im already getting my nose. but i want to get my ear. like barbell? so what's the difference between Scaffold and Industrial?

- They're the same thing. Different places call them different things.

- Q: Said chrysanthemum disc scaffolding system, disc scaffolding system, wheel type scaffolding system, buckle scaffold, layher frame

- Crossbar HG-30 3001.67HG-60 6002.82HG-90 9003.97HG-120 12005.12HG-150 15006.28

- Q: How to solve the problem of scaffold pipe repair

- ST100 type hyperbolic steel pipe straightening machine adopts staggered rolling rotary straightening system, the 4 line rolling wheel revolves around the steel pipe:

- Q: Mobile scaffolding accessories prices

- The cross rod is also called the diagonal pull rod, and is a cross connecting rod which is vertically connected with the two door frames. The part of both ends of the rod part is punched with a pin hole, and the locking pin on the vertical rod of the door and the frame is locked when assembling.

- Q: When putting up old scaffolding, a mistake was made and it had to come down.Long story short, the connectors between the vertical and horizontal poles (which were hammered in) are stuck.Any ideas for getting them out?Thanks.

- Heat the female connection with a torch. The outer connection will expand from the heat. Heat the connection hot enough not to touch but not cherry red. Put a pipe wrench on male side of tubing where its is cool and tap wrench with a hammer and it will come apart. If possible lay the scaffold on its size for better leverage.

- Q: According to the standard set up double scaffolding scaffolding to the number of meters per square meter

- The span, the rod step is easy to calculate, I have done the program in general 4.4.8 meters

- Q: what are two burdens for each character? What action does each character indicate that she or he is indeed free from their burdens?

- Tell me what you know and I will elaborate. I had to read this book for a class and hated it, but I won't do your homework for you. I will help if you show you read it yourself and put in some effort we can see

- Q: what is the height of a scaffold if the person is 6ft tall?

- Whatever they set it at. It could be 1 foot, 4 feet, or 20 feet. How tall a person is, is irrelevant.

- Q: what do you think?pain wise? i know it's going to hurt as it's a peircing (duh) but will it hurt especially as it's two thick pieces of cartilage?

- sounds hott!! XD take alot of advile or novacain before you get it done, trust me it works!

Send your message to us

Construction Galvanized Steel Kwikstage Scaffolding System with High Quality CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords