Kwikstage Modular Scaffolding System with Top Quality CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Kwikstage Modular Scaffolding System with Top Quality

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Surface:

Material.:

Thickness:

Descriptions of Kwikstage Modular Scaffolding System with Top Quality

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

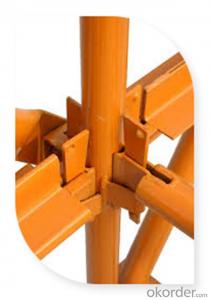

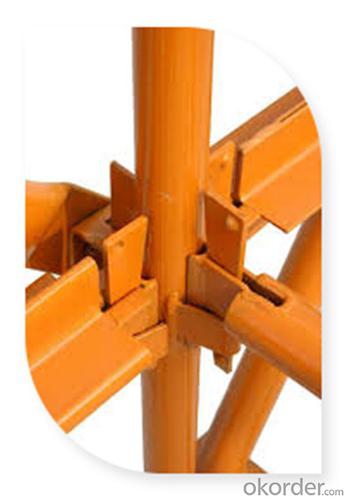

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

The Accessories of Kwikstage Modular Scaffolding System with Top Quality

The main items of Kwikstage scaffolding system

ITEMS SPECIFICATION WEIGHT STANDARD

(VERTICAL)48.3*4.0*3000/2500/2000/1500/1000mm

painted/hot dip galvanized/ect.

steel pipe16.94/14.34/11.53/8.86/6.13kg LEDGER

(HORIZONTAL)48.3*3.2*2400/1800/1200/700mm

painted/hot dip galvanized/etc.

steel pipe9.1/6.85/5.13/3.24kg TRANSOM 2400/1800/1200/700mm

painted/hot dip galvanized/etc.19.92/12.08/10.79/7.79kg BRACE 2400*2000mm/2500/3000mm

pained/hot dip galvanized/etc.9.38/10.35/11.41kg HOPUP BRACKET one board/two board/three board

painted/hot dip galvanized/etc.1.84/4.99/8.58kg The other items of Kwikstage scaffolding system

TIE BAR 2400/1800/1200/700mm

painted/hot dip galvanized/etc.5.41/4.15/2.77/1.72kg STEEL BOARD 2400/1800/1200/700mm

painted/hot dip galvanized/etc.14.5/10.93/7.68/4.94kg END TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.1.12kg TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.0.72kg BASE JACK and U HEAD 38*4.0*650mm/u head

painted/hot dip galvanized/etc.3.69/4.63kg FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: I would like a scaffold piercing, but my parents aren't going to let me have two cartilage piercings at once. So, can they be done separately, as in weeks apart?

- Technically yes but it is better to have them done at the same time so the holes are aligned properly. It is better to get them done at the same time, as the second piercing will be less painful because you are all adrenalin-ed up! Probably cheaper too.

- Q: What are the advantages and disadvantages of the fastener type steel pipe scaffold and bowl buckle steel tube scaffold

- (5) safe and reliable: the joint design, taking into account the upper bowl buckle spiral friction and self gravity, so that the connector has a reliable self-locking capacity. The load acting on the cross bar is transferred to the vertical rod through the lower bowl buckle, and the lower bowl buckle has a strong shearing force (the maximum is 199KN). Even if the upper bowl buckle is not pressed, the joint of the cross bar is not caused by an accident. At the same time equipped with a safety net support, inter bar, foot board, block board, ladder. Pick up the beam, wall support and other rod accessories, the use of safe and reliable.

- Q: Mobile scaffolding accessories prices

- The cross rod is also called the diagonal pull rod, and is a cross connecting rod which is vertically connected with the two door frames. The part of both ends of the rod part is punched with a pin hole, and the locking pin on the vertical rod of the door and the frame is locked when assembling.

- Q: Method for inspection of foot hand frame fittings

- Or "low pressure fluid delivery welded steel pipe" GBT 3092

- Q: Write a scaffold method for 743,425 divided by 365EASY 10 points

- use a calculator you punk, nobody writes out division anymore, grab your ti-84 and type it out... there's your scaffold method jerk.

- Q: Specification for construction steel pipe scaffolding and construction safety rules?

- 48mmX3.0mX6m is a national standard, but you can pay attention when you buy the shelf, generally said that they are 3 thick, but the pipe is under the difference, but the number of questions. There are 2.5 under the difference also has a difference of 111 layers of this standard is certainly enough, most of the South with a cover of 20 layers of it, they are basically the same price

- Q: I know its between chapters one and two, duh. Haha, but yeah, I needa do this thing on Edmodo for school, but i accidentally left my book in my locker.):I tried looking at online versions, but you know it's so hard, right? Looking and seeing all these different versions and I cant find the place...I need where she entered the scaffold because I need to cite where she thinks about how she's accepted her quot;sinquot;. So yeah~ PLEASE HELP! ( gt; . lt; )

- i'm no longer completely constructive of the answer to this actual question, yet I only finished a unit in this novel and could like to help with any extra questions...be satisfied to invite -Alice

- Q: I know people have different pain thresholds. But I was wondering if it was more painful than a lobe piercing? It will be done with a needle and are they aloud to freeze it? Or is it not needed?

- I got my lobes pierced 5 years before my industrial so I can't compare the pain but everyone says industrial. Idk if they can freeze or not. The pain is completely tolerable.

- Q: What could you do with 100,000 jumbo cotton balls, 50 gallons of honey, and three story scaffolding?

- ummmm oh i got a good one i hope and that is to build the world's largest bee's hive. plus they make more honey and i would have tons of money, pretty sweet isn't it.

- Q: improper design of formwork and scaffolding, not adequate braces and supports, improper handling, corrosion of material is several factor of formwork and scaffolding failure. it is estimated that more than 3000 accidents involving falls from scaffolds and 30 fatalities

- Improper assembly seems to be a big one. Workers often neglect to install the internal diagonal from upper corner to opposite lower corner when it comes to scaffolding. Formwork usually fails by inadequate bracing at the bottom as hydrostatic pressure builds. This can be mitigated to some extent by allowing the concrete to set up a bit before pouring the next layer. For earth formwork, you have to be real careful about expansive clay becoming saturated and overwhelming the bracing as it expands.

Send your message to us

Kwikstage Modular Scaffolding System with Top Quality CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords