| Packaging Details: | 20GP , safe and water-proof packing |

|---|---|

| Delivery Detail: | 15days |

2. Efficient &Exclusive

3.Competitive price

4. Simple transportation

Features

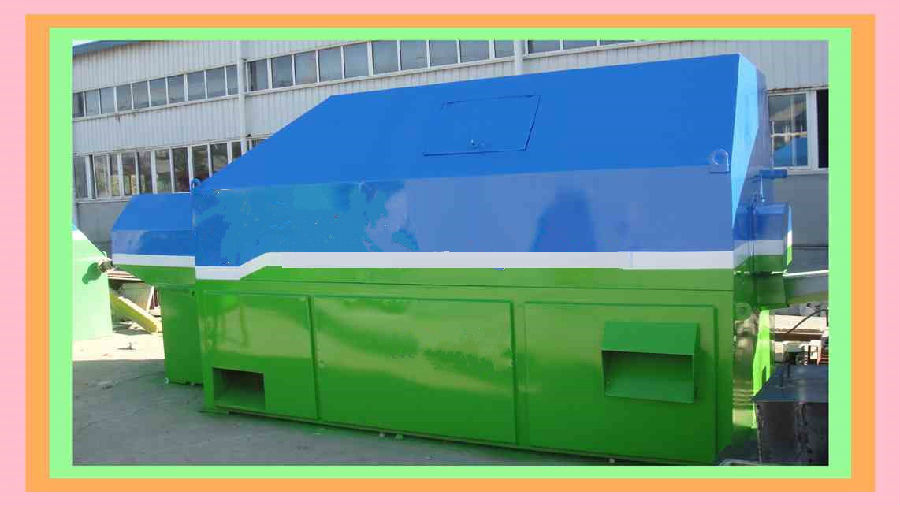

The position of the overflow tank design,and equipped with automatic high pressure spray pipe,is the most ideal mixing plant pf environmental protection and energy saving products.

The main technical parameters

| Item | Unit | |||

| product Model | - | THS10 | THS20 | ZSF30 |

| Screening Capability | t/h | 10-20 | 20-30 | 30-40 |

Stone size screened | mm | - | >5 | >5 |

| stand size screened | mm | - | 1-5 | 1-5 |

| Power of main Body | kw | 7.5 | 7 | 5.5 |

| Dimensions | mm | 6660*1200*3100 | 6360*1750*2600 | 4680*2220*2290 |

| Mixing Trucks Number | Qty | <10< span=""> | 10-30 | >30 |

| weight of main body | kg | 2000 | 5000 | 4000 |

About product