Concrete Block Machine, Block Making Machine, Block Machine, Brick Making Machine

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company Profile:

HONCHA established since 1985, has become one of the leading and reputable manufacturers of concrete block machinery in

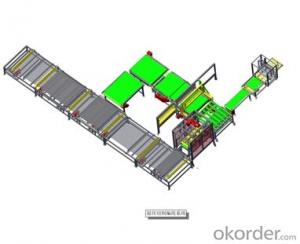

Our strength is we are able to provide customized turnkey full-auto block plant for high-end users who has strick demanding for block machine quality.

Machine Functions:

Honcha Block Making Machine is a multi-purpose block machine that is designed to meet the mass production of various kinds of concrete masonry blocks like solid brick, blocks, pavers, slabs, curbs, interlocking types etc by just changing different moulds on the same block machine.

Models Available:

We mainly have 2 series block machines: QT series for low-memidium customers and Hercules Series for high end customers who need German quality block machine.

QT series production capacity is from 8,000 to 13,000 pcs per day. It includes QT6-15, QT8-15, QT9-15 block machine models.

Specification:

| Block Machine Model | QT6-15 | QT8-15 | QT9-15 |

| Pallet Size | 860*680mm | 1380*580mm | 1380*680mm |

| Max. Moulding Area | 800x620x40–200mm | 800x620x40–200mm | 1280x620x40-200mm |

| Blocks per cycle 8" | 6 | 6+3 halfs | 9 |

| Gross Weight | 6.8T | 9.6T | 10.5T |

| Pressure Rating | 12 – 25 MPa | 12 – 25 MPa | 12 – 25 MPa |

| Vibration | 60 – 90 kN | 60 – 90 kN | 60 – 90 kN |

| Vibration Frequency | 60 – 90 kN | 60 – 90 kN | 60 – 90 kN |

| Cycle Time | 20s (5-8s extra time for face material adding) | ||

| Power Consumption | 46.2 kW | 33.7 kW | 46.2 kW |

Machine Advantages:

1. Frequency Controlled Vibration

2.Visualized User-friendly Touch-Screen Control Panel

3. Janpanese Omron PLC

2. Solid Frame for heavy, high-dust conditions

3.Imported Electric Parts:

1)French Schneider Contractor &Air Switch

2)American Emerson Frequency Converter

3) Siemens Motors and Yuken Valves

4.Multi-step processing and heat-treament for main parts for wear-resistant purposes.

5. Patented Material Feeding for the even-distribution of mixed materials(Patent No.:ZL 200720008804.1))

6. Reduced Cycle Time by Special-designed feeding rollers.

Why choose HONCHA?

1. Trusted and Experienced since 1985 as the block machine industry expert.

2. Exported to over 120 overseas countries and regions, well-recognized brand in China and overseas.

3. Owning the largest fully-automatic block machine production manufacturing base in China.

4. Experienced in catering for different needs of customers, Indivisual Project Proposal for different levels of customers.

5.Good Serive Package, Free Machine Training at headquarters,Scheduled Plant Visit.

Your Block Project-- Our Machine:

- Q: Brief introduction of cement brick machine

- Can be said to invest less, quick, is a lot of investors to invest in the popular industry.

- Q: Brief introduction of the brick machine

- The purpose of the utility model is to overcome the above shortcomings and provide an integrated hydraulic brick making machine which solves the problems of the existing brick making machine when the noise is large, the power consumption is high, the auxiliary tools are needed and so on.

- Q: The development of brick machine

- 2, mixer. Applicable to a variety of concrete products, forced mixing, stirring, mixing the material from the conveyor into the molding machine; 3, forming machine. Intelligent control by the PLC computer, the use of hydraulic transmission, vibration compression molding.

- Q: Automatic concrete brick machine bearing how to choose?

- In order to ensure the safety of the operator and equipment, to stop the repair, adjustment and finishing operations in the machine operation, to prevent the opening of the door. When checking the fasteners can loose, you should point to see the rotor on both sides of the pressure plate hammer plate pressure plate screws;

- Q: Installation and commissioning of hydraulic press

- 1, check the brick machine in the transport process is damaged or deformation (especially pay attention to hydraulic pipe).

- Q: How can a free brick brick brick machine be classified?

- According to the empty arrangement: divided into single row of holes, double row of holes, multi-row of blocks.

- Q: The scope of application of building waste brick machine

- Bulk density and water absorption is better than ordinary concrete perforated brick. Between sintered bricks and non-sintered bricks. Production structure The structural properties of raw materials have not changed. Its dry shrinkage, thermal conductivity than the average concrete products to the construction of a very favorable role.

- Q: Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- New, old mold, be sure to avoid collision, bump, civilized assembly, pay attention to protect the mold;

- Q: What is the principle of vacuum brick machine

- Vacuum brick machine for coal gangue, shale, fly ash and clay and other raw materials to produce all kinds of hollow brick. The machine is equipped with wear-resistant metal powder spray coating technology; superior mixing shaft, mud knife shaft and body up and down body, etc., are aging, quenching and tempering, quenching; reducer gear are hard tooth; Pressure patented technology, a substantial increase in equipment life.

- Q: How does the economical brick machine use the building waste brick?

- part of which is the construction waste into recycled aggregate, the other part is the recycled aggregate into concrete blocks or tiles products,

Send your message to us

Concrete Block Machine, Block Making Machine, Block Machine, Brick Making Machine

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords