Gantry Scraper Reclaimer,Mining Equipment,Reclaimer,Scraper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

Gantry scraper reclaimer is a kind of large mix blending technology processing equipment and the scraper reclaimer is located on a portal frame. The pitch of the reclaimer is mechanical that is the steel rope movement by the drum which is located near the center column. One end of the portal frame and the center column are connected by slewing bearing, the other end is supported on the circular orbit of the upper wall of the material retaining wall, the turning of the reclaimer is accomplished by the trolley drive on the circular track. The gantry scraper reclaimer can be used in indoor or outdoor, and it has been widely used in coal mine, coal chemical industry, iron ore, electricity and other industries.

The gantry scraper reclaimer has two types: full gantry type and semi gantry type. The full gantry scraper reclaimer and side stacker are matched to operate. Semi gantry type scraper reclaimer has the retaining wall, and with the stacker machine of crane pairing use.

The gantry scraper reclaimer is 25m ~ 65m in accordance with the track span, it can also adjust the track according to the actual situation of the material yard. The scraper reclaimer system can be a single scraper system or a double scraper reclaimer system.

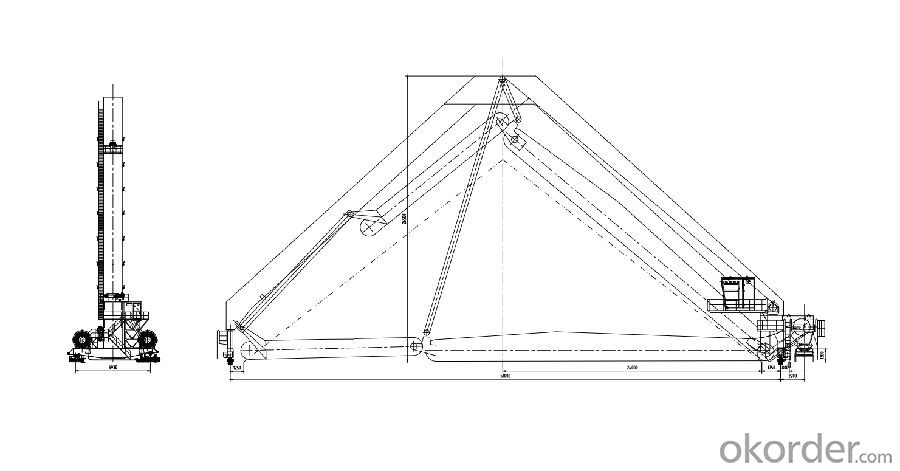

Overall Drawing

Technical Parameters

Model | Unit | MQG1000.36 | MQG750.46 | MQG1600.40 | MQG450.32 | MQG1200.33 | MQG600.38 | MQG800.47 | MQG1000.50 | MQG1500.54 | |

Production Capacity | t/h | 1000 | 750 | 1600 | 450 | 1200 | 600 | 800 | 1000 | 1500 | |

Characteristic of Material | Application Materials | Coal, coke, limestone, bauxite, iron ore, stone, clay pellets and other bulk materials. | |||||||||

Density | t/m³ | 0.5~2.5 | |||||||||

Granularity | mm | 0~300 | |||||||||

Travelling Speed | m | 0~15 Continuously Viable | |||||||||

Span | m | 36 | 46 | 40 | 32 | 33 | 38 | 47 | 50 | 54 | |

Max. Wheel Pressure | 250/300/350 | ||||||||||

Steel Track | Q100/Q80 | ||||||||||

Power Supply | Cable Drum/Safety Trolley Line | ||||||||||

Communication Mode | Cable Drum/Safety Trolley Line/Wireless | ||||||||||

Control Mode | |||||||||||

Feature

The structure of the gantry scraper reclaimer is reasonable, part of the weight of the gantry and scraper reclaimer is borne by the retaining wall, makes the stress state of the lower part of the center column is obviously improved. In this way, the bearing capacity of the slewing bearing and the lower part of the center column is smaller and the operation is more stable.

The gantry scraper reclaimer is compact in structure and does not need to design counterweight, the lower equipment of stacker occupies less space. The gantry scraper reclaimer has the advantages of good homogenization effect, large material reserves, small occupied area and high degree of automation. It can realize the unmanned operation of the whole machine and the integration of electricity and liquid and so on.

Main Components

- Travelling End Beam

The traveling end beam is located on the parallel track on both sides of the pile, the end beam is equipped with drive wheel set and driven wheel set, the travelling speed of end beam can be adjusted by frequency converter. According to the span and the capacity of the reclaimer, one or more driving units can be installed on one end beam.

- Portal Frame

The steel structure of two walking end beams is connected, one end of the connecting end beam is fixedly connected, and the other end is hinged.

- Reclaimer Arm

One end of reclaimer arm is fixed on the portal frame through the wire rope and the pulley block system, and the other end of reclaimer arm is hinged on the travelling end beam. Two parallel chains are installed on the reclaimer arm, the scraper is installed on the chain at the same interval, chain track and scraper guide track are installed on the reclaimer arm, a group of tightener sprocket wheel sets are installed at the head of the reclaimer arm, drive sprocket wheel sets and discharge funnel are mounted at the rear end of the reclaimer arm.

- Rotating Shaft of Reclaimer Arm

The rotating shaft of the reclaimer arm is located at the bottom of the unloading material near the bottom of the stacker, and the material collecting arm can change the angle through the rotating shaft, so that the material can be taken from the side of the stacker.

- Winch

The winch is fixed on the gantry frame, and the material can be rotated up and down around the rotating shaft through the wire rope and pulley block system, and the lifting point is close to the head of the reclaimer arm.

- Scraper Chain Drive

Scraper chain drive is installed on the drive shaft of the driving sprocket wheels sets at the unloading end of the reclaimer arm, this drive has only one constant speed in normal.

- Cable Reel

The power supply and central control of the reclaimer are realized by a fixed cable pit in the track accessories, the cable reel is mounted on the fixed end beam. When the reclaimer moves, the cable can carry out the power supply and central control of the reclaimer through the cable reel.

FAQ

Is the scraper reclaimer system using single scraper or double scraper?

Using single scraper or double scraper must be combined with productivity requirements and scraper arrangement space, and the most reasonable layout form is selected by detailed design.

Is there any obstacle to land transportation of this large equipment?

Considering the different forms of equipment transportation, in the case of land transportation, the equipment design stage according to the route transport restrictions to carry out the disintegration scheme, to ensure the unimpeded of land transportation.

Is the equipment which leave the factory equipped with random spare parts or vulnerable parts?

According to the characteristics of the equipment for the use of high frequency, easy to wear parts with random spare parts, also provide spare parts list for the owners to choose, the spare parts should be signed with the owner what has a greater impact on cost.

How long is the equipment maintenance intervals?

Different parts of the equipment maintenance intervals and methods are different, and refer to the equipment maintenance instructions.

Send your message to us

Gantry Scraper Reclaimer,Mining Equipment,Reclaimer,Scraper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords