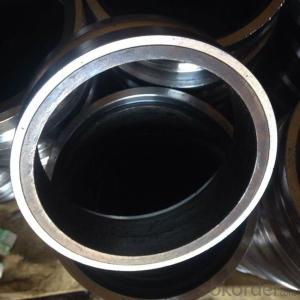

Concrete Pumps Spare Parts Welding Flange Double Layer DN125MM X 35MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

The Concrete Pumps Spare Parts Welding Flange Double Layer DN125MM X 35MM normally made by special MN13-4 insert, to make sure the quanlity of elbows according to customer’s requests we usually keep the content of MN strictly over 15%, it will have a longer life as well, package will be in plywood box or cartons and put into container.

Scope of Application of the Goods

The Concrete Pumps Spare Parts Welding Flange Double Layer DN125MM X 35MM is a concrete pumps parts for combined use with other concrete parts in for concrete pumps and truck pumps. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This seals can only be used in Schwing type concrete pumps and truck pumps as well, but not in any other operations.

Product Advantages:

OKorder's Concrete Pumps Spare Parts Welding Flange Double Layer DN125MM X 35MM Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (5-10 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

Specifications:

DN:125MM

Width:35MM

Material: ST52,MN

FAQ:

Q1: How long about delivery time Concrete Pumps Spare Parts Welding Flange Double Layer DN125MM X 35MM ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Concrete Pumps Spare Parts Welding Flange Double Layer DN125MM X 35MM?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically 7 to 30 workdays.

Q4: If we can produce some goods according to customers request?

A4: Yes, we can produce Welding Flange Double Layer DN125MM X 35MM according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design for porduction of seals.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world.

- Q: How can a faulty filter affect the pumping process?

- A faulty filter can impede the pumping process by allowing debris, contaminants, or particles to pass through and clog or damage the pump components. This can result in reduced efficiency, increased wear and tear, decreased flow rates, and potential pump failure.

- Q: How often should hopper grate clamps be inspected or replaced in a concrete pump?

- Regular inspections of hopper grate clamps in a concrete pump are essential to ensure they are functioning correctly. It is recommended to inspect them on a monthly basis. However, the frequency of inspection may vary based on how frequently the pump is used and the operating conditions it is subjected to. If the concrete pump is used extensively or exposed to harsh environments, more frequent inspections may be needed, such as every two weeks or even weekly. Conversely, if the pump is used infrequently or operates in less demanding conditions, inspections can be done less frequently, such as every two to three months. The objective of these inspections is to detect any signs of wear, damage, or deterioration in the hopper grate clamps. Any loose or worn-out clamps should be replaced promptly to prevent accidents or interruptions during concrete pumping operations. Ensuring the hopper grate clamps are in good condition is crucial for safety and to effectively secure the hopper grate, preventing any undesired material spillage. By conducting regular inspections and timely replacements of hopper grate clamps, the efficiency and reliability of the concrete pump can be maintained. This will ensure uninterrupted operation and minimize the risk of potential issues.

- Q: What are the indicators of a faulty concrete pump seal?

- There are several indicators that can suggest a faulty concrete pump seal. These include: 1. Leakage: One of the most obvious signs of a faulty seal is leakage of concrete or water around the seal area. If you notice any fluid seeping out from the seal, it is a clear indication of a problem. 2. Reduced pumping efficiency: A faulty seal can result in reduced pumping efficiency. If you notice that the concrete pump is not delivering the expected amount of concrete or is struggling to pump the material, it could be due to a seal issue. 3. Increased noise and vibration: A faulty seal can cause increased noise and vibration during the operation of the concrete pump. Unusual sounds or excessive vibration can indicate that the seal is not functioning properly, and further inspection may be required. 4. Premature wear and tear: If the seal is faulty, it can lead to premature wear and tear of other components in the pump system. This can be observed through the degradation of other parts such as gaskets, bearings, or pistons. Regular inspections can help identify such issues. 5. Inconsistent pressure: A faulty seal can result in inconsistent pressure while pumping concrete. If you notice variations in the pressure output or irregular flow of concrete, it may be a sign of a seal problem. 6. Excessive heat: Another indicator of a faulty seal is the generation of excessive heat in the seal area. If the seal is not functioning properly, it can cause friction and heat buildup, which can be felt or observed by touch. It is important to address any indication of a faulty concrete pump seal promptly to prevent further damage to the pump system and ensure the safety and efficiency of the operation. Consulting a professional or contacting the manufacturer for guidance and repair is recommended in such cases.

- Q: Can concrete pump spare parts be coated with UV-resistant coatings for outdoor applications?

- Yes, concrete pump spare parts can be coated with UV-resistant coatings for outdoor applications. UV-resistant coatings are specifically designed to protect surfaces from the damaging effects of ultraviolet (UV) radiation, which can cause fading, cracking, and deterioration over time. By applying UV-resistant coatings to concrete pump spare parts, the parts can be safeguarded against the harmful effects of prolonged exposure to sunlight and other environmental elements. This helps to extend the lifespan of the spare parts and ensures their optimal performance in outdoor applications. Additionally, UV-resistant coatings can also provide added protection against other forms of weathering, such as moisture, temperature fluctuations, and chemical exposure. Therefore, coating concrete pump spare parts with UV-resistant coatings is a recommended practice to enhance their durability and maintain their functionality in outdoor settings.

- Q: What is the purpose of a concrete pump agitator motor?

- The purpose of a concrete pump agitator motor is to ensure the consistency and quality of the concrete mixture being pumped. It is responsible for keeping the concrete mixture well-mixed and preventing it from settling or separating during the pumping process. The agitator motor helps to maintain a uniform and homogenous mixture, which is crucial for achieving strong and durable concrete structures. By continuously agitating the concrete inside the pump, the motor helps to prevent any blockages or clogs that could potentially disrupt the pumping operation. Overall, the purpose of a concrete pump agitator motor is to enhance the efficiency and effectiveness of the concrete pumping process, ultimately resulting in better construction outcomes.

- Q: What is the farthest pumping distance of concrete pump truck?

- Concrete pump, commonly known as to pump, or supporting pump, pumping height is determined by the power of the engine, 08 years in Guangzhou pearl, vanda heavy section pump made of C100 high strength concrete vertical height of 411 meters world record, the engine for the 572KW

- Q: Are there any specific maintenance practices for concrete pump spare parts?

- Concrete pump spare parts should be regularly inspected for signs of wear or damage. This involves checking for visible defects like cracks, leaks, or any other issues. If any problems are found, the spare parts should be immediately replaced or repaired to prevent further damage. Regular cleaning is also essential for concrete pump spare parts. These parts often come into contact with cement, water, and other substances that can cause build-up and affect their performance. Cleaning them regularly will remove debris and residue, ensuring optimal functionality. Lubrication is another important maintenance practice for concrete pump spare parts. Properly lubricating moving components like bearings, seals, and pistons reduces friction and wear, extending the lifespan of the parts. It's crucial to use the correct lubricants recommended by the manufacturer and follow their application guidelines. Proper storage is also vital for maintaining spare parts. They should be stored in a clean, dry environment, away from chemicals or substances that could damage them. Additionally, spare parts should be protected from physical damage, such as being dropped or bumped. Lastly, it's recommended to adhere to the manufacturer's maintenance and replacement guidelines. Regular servicing and inspections by qualified technicians can help identify potential issues early on and prevent major breakdowns or failures. In summary, following specific maintenance practices like regular inspection, cleaning, lubrication, proper storage, and adherence to manufacturer's guidelines are crucial for ensuring optimal performance and longevity of concrete pump spare parts.

- Q: Why would the plugging concrete pump pipe

- Pump operator in pumping construction should concentrate, always pay attention to pumping pressure meter readings, once found that the pressure gauge reading suddenly increased, should immediately anti pump 2-3 stroke, and then pump, pipe can be excluded

- Q: How does the concrete pump work?

- Pump in place should be flat and solid, without obstacles around, no overhead transmission line. The pump shall not be parked on the slope.

- Q: What is the function of a concrete pump hydraulic motor?

- The function of a concrete pump hydraulic motor is to provide the necessary power and force required to operate the concrete pump. The hydraulic motor is responsible for converting hydraulic energy into mechanical energy, which allows the pump to work efficiently and effectively. It drives the pumping mechanism, allowing the concrete to be pumped through the pipeline and delivered to the desired location. The hydraulic motor also controls the speed and direction of the pump, enabling precise placement of the concrete. Overall, the concrete pump hydraulic motor plays a crucial role in ensuring the smooth operation and successful delivery of concrete in construction projects.

Send your message to us

Concrete Pumps Spare Parts Welding Flange Double Layer DN125MM X 35MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords