Concrete Pump Truck Parts Elbow Bend DN100 R285 90DGR 148MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1.Adopt the new plasma quenching and chromium plating process, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

2.Service life: 55000-150000 CBM Concrete. The elbow possesses good toughness properties, and can well protect the inside.

3.Possess quality certification of ISO 9001:2000. Can pass CE test.

4.We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

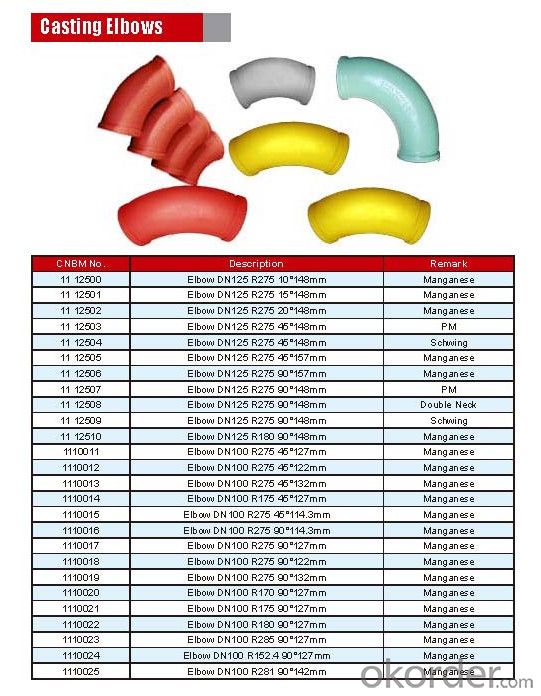

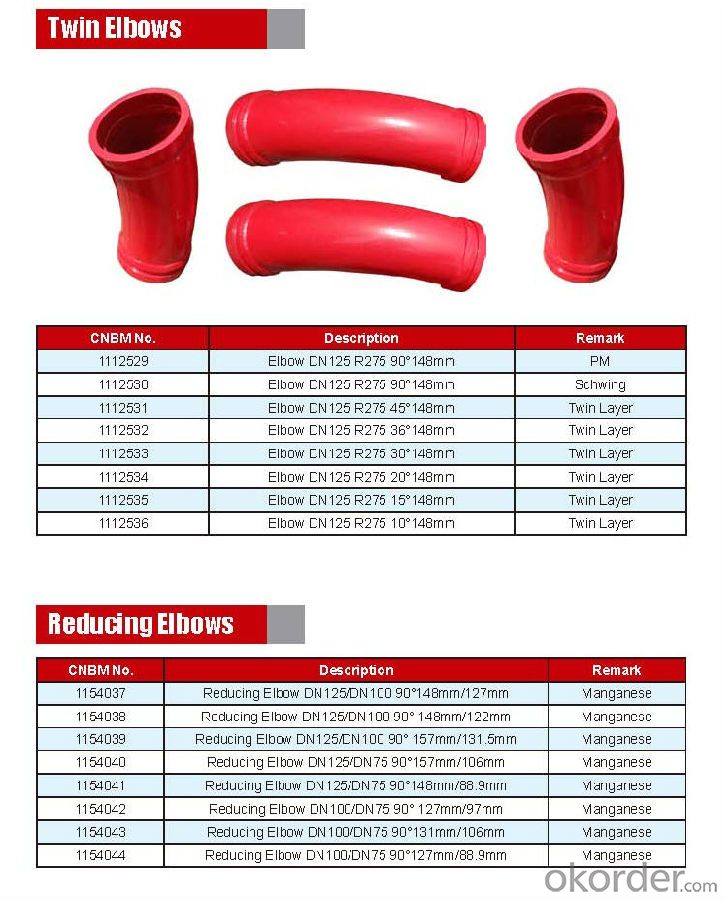

Product Specifications:

Technology: Cast

Dimension: DN100

Radius: 285mm

Degree: 90D

Material: Mn13-4

Weight: 13.5kg

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Every 70pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for more than ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: What kind of concrete pump truck?

- But the drawback is that the delivery speed is slow. Delivery height is better than vehicular pump. Among them, the more moderate is the car pump. But the advantage is that the arm pump can do, it can do, that is, when construction, need to install the pump ahead of time, relatively troublesome. But the relative pump speed and delivery height are higher

- Q: Are there any specific brands or manufacturers that are recommended for concrete pump spare parts?

- Yes, there are several brands and manufacturers that are highly recommended for concrete pump spare parts. Some of the top brands in the industry include Putzmeister, Schwing, Sany, and Zoomlion. These brands are known for their high-quality products, reliability, and durability. They have a wide range of spare parts available for various models of concrete pumps, ensuring that customers can find the specific parts they need. Additionally, these brands have established a strong reputation in the market and have a vast network of dealers and distributors worldwide, making it easier for customers to access their spare parts. It is always advisable to choose spare parts from reputable brands and manufacturers to ensure the longevity and performance of your concrete pump.

- Q: What are the different types of concrete pump hopper pins?

- There are several types of concrete pump hopper pins, including snap pins, lynch pins, and clevis pins. These pins are used to secure the hopper to the pump and ensure it stays in place during operation.

- Q: How can one ensure proper functioning of concrete pump spare parts after installation?

- To ensure proper functioning of concrete pump spare parts after installation, it is important to follow a few key steps. Firstly, it is crucial to carefully inspect and clean the parts before installation to ensure they are free from any debris or damage. Additionally, it is essential to use high-quality parts from reputable manufacturers to ensure durability and reliability. Regular maintenance and lubrication of the spare parts is also necessary to prevent wear and tear. Lastly, it is important to operate the concrete pump within its specified limits and avoid overloading, as this can cause stress on the spare parts and lead to malfunctioning.

- Q: How can you determine when a concrete pump pipe needs to be replaced?

- There are several factors to consider when determining if a concrete pump pipe needs to be replaced. 1. Visual Inspection: Conduct a thorough visual inspection of the pipe. Look for any cracks, damage, or signs of wear and tear. Pay particular attention to the ends of the pipe where it connects to the pump and nozzle, as these areas are more prone to damage. 2. Performance: Observe the performance of the concrete pump. If you notice a decrease in pumping efficiency, such as reduced output or difficulties in maintaining pressure, it could indicate a problem with the pipe. Additionally, if there is excessive leakage or blockages in the pipe, it may be a sign that replacement is necessary. 3. Age and Usage: Consider the age of the pipe and the amount of usage it has undergone. Concrete pump pipes have a limited lifespan, and with time and extensive use, they can become worn out and lose their structural integrity. If the pipe is old and has been used extensively, it may be time to replace it. 4. Regular Maintenance and Repairs: If the pipe has undergone frequent repairs or maintenance, it could be an indication that it is nearing the end of its lifespan. While regular maintenance can prolong the life of a concrete pump pipe, if it has reached a point where repairs are becoming more frequent and costly, it may be more cost-effective to replace it. 5. Safety Considerations: Safety should be a top priority when determining if a concrete pump pipe needs replacement. If there are any significant structural issues or concerns about the pipe's ability to handle the pressure, it is essential to replace it to avoid any potential accidents or hazardous situations. Ultimately, the decision to replace a concrete pump pipe should be based on a combination of visual inspection, performance evaluation, age, usage, regular maintenance, and safety considerations. It is advisable to consult with a professional or experienced technician who can assess the pipe's condition and provide expert advice on whether replacement is necessary.

- Q: How can one determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts?

- Determining the appropriate viscosity and temperature range for lubricants used in concrete pump spare parts requires the consideration of multiple factors. Below are some steps that can assist in determining the suitable viscosity and temperature range: 1. Refer to the manufacturer's recommendations: To begin with, consult the specific guidelines or recommendations provided by the manufacturer for the concrete pump spare parts. The manufacturer may specify the required viscosity and temperature range for the lubricants used in their equipment. 2. Gain a clear understanding of the operating conditions: It is essential to have a comprehensive understanding of the operating conditions in which the concrete pump spare parts will be utilized. Factors such as ambient temperature, pump speed, load, and pressure should be taken into account. These factors can significantly impact the viscosity requirements and temperature range of the lubricant. 3. Assess the performance characteristics of the lubricant: Different lubricants possess distinct performance characteristics that make them suitable for particular applications. Look for lubricants specifically formulated for heavy-duty tasks, offering excellent wear protection and displaying good thermal stability. These performance characteristics ensure that the lubricant can endure the demanding conditions of a concrete pump. 4. Viscosity requirements: The viscosity of the lubricant plays a crucial role in ensuring proper lubrication and safeguarding of the concrete pump spare parts. Heavy-duty applications generally require higher viscosity lubricants, while lighter loads may be better suited with lower viscosity lubricants. The viscosity requirements may also differ depending on the specific pump parts, such as bearings, gears, or seals. Referring to the manufacturer's guidelines and seeking advice from lubricant suppliers can help determine the ideal viscosity range for the concrete pump spare parts. 5. Consider the temperature range: The temperature range within which the concrete pump operates is another significant aspect to consider. Lubricants should be capable of maintaining their viscosity and performance across the expected temperature range. Extreme temperatures can cause lubricants to lose their effectiveness, potentially leading to equipment damage or failure. Consequently, it is important to select lubricants with a temperature range suitable for the operating conditions of the concrete pump. 6. Consult with experts: If uncertainty persists regarding the appropriate viscosity and temperature range, it is advisable to seek advice from lubricant manufacturers, suppliers, or industry experts. They can offer valuable insights and recommendations based on their expertise and experience with concrete pump spare parts. By adhering to the manufacturer's recommendations, comprehending the operating conditions, evaluating the lubricant's performance characteristics, and seeking professional advice, it becomes possible to determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts. This will ensure optimal lubrication and extend the lifespan of the equipment.

- Q: How can the concrete pump be installed and used?

- Concrete conveying pipe joints should be sealed tightly, pipe should be firmly connected. The vertical pipe shall be no less than 10m horizontal pipe with check valve. The vertical pipe shall not be attached directly to the outlet of the concrete pump.

- Q: What are the indications of a faulty concrete pump hydraulic motor?

- Some indications of a faulty concrete pump hydraulic motor may include decreased pumping efficiency, irregular or inconsistent flow of concrete, unusual noises or vibrations, leaks or drips in the hydraulic system, excessive heat in the motor, or difficulty in starting or stopping the motor.

- Q: Is the main pump of the concrete pump electric control or hydraulic control?

- The main pump behind the oil pump to provide the size of the oil with the greater the current the higher the higher the higher the displacement,

- Q: How do I ensure the compatibility of mechanical components in concrete pump spare parts?

- To ensure the compatibility of mechanical components in concrete pump spare parts, it is crucial to consider several factors. First, it is important to identify the specific make and model of the concrete pump and its components. This information will help in sourcing the correct spare parts that are designed to fit and function properly with the existing system. Additionally, it is recommended to consult the manufacturer's documentation or reach out to their customer support for guidance. They can provide detailed specifications and compatibility guidelines for the mechanical components. It is essential to match the dimensions, tolerances, and materials of the spare parts to the original components to ensure a proper fit and optimal performance. Furthermore, working with reputable suppliers or distributors who specialize in concrete pump spare parts can greatly enhance compatibility assurance. These professionals have extensive knowledge and experience in the industry and can guide you in selecting the right components that are compatible with your specific concrete pump model. Regular maintenance and inspection of the mechanical components are also essential to identify any wear or damage. By addressing any issues promptly and replacing worn-out parts with compatible ones, you can ensure the overall compatibility and longevity of the mechanical components in your concrete pump spare parts.

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN100 R285 90DGR 148MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords