Concrete Pipeline DN150 Cleaning Ball And Column

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

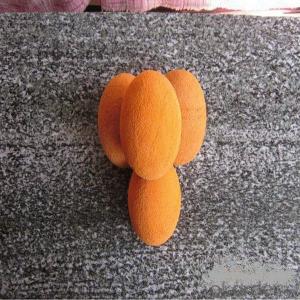

Concrete Pipeline DN150 Cleaning Ball And Column

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q: Is work in rubber products harmful to health?

- Work in a rubber factory is harmful to health.When the rubber vulcanization molding, high temperature reaction releases sulfur dioxide, sulfur dioxide, sulfur dioxide, hydrogen sulfide gas three. If the workshop dust suction measures are not enough, these gases will pollute the workshop environment, workers will suck into the body, endanger health.

- Q: What are the application fields of waste tire rubber powder?

- Waste tire rubber powder from 900 to 1200 waste tire as the main raw material, the production method of low temperature refrigeration by air turbine (0.425mm) 40 mesh to 200 mesh (0.0750mm) crumb rubber with high fineness, tensile strength, the proportion of small, good liquidity.

- Q: Why is rubber forest a green desert?

- Long ago, the people have the knowledge of the use of wild rubber. Before Columbo came to the new world, no one outside the Americas knew that there was a species called rubber, and never thought that there would be a magical liquid out of the tree trunk that could change the progress of human civilization one day.

- Q: Bought a mouse pad, a little rubber, how to remove?

- The best way is to put the balcony outside, let it go to taste naturally, generally a few days can be, do not expose to the sun, we are all solved like this.The mouse pad more or less have to taste, taste the most common cloth pad, because the part is in addition to cloth rubber, relatively the rubber is not very high, even as the high-end gaming mouse pad will have a pungent taste, which is unable to avoid, but really I don't smell in use also, not in the mood to smell, unless you put the nose close to become obvious.It is best not to wash casually or rub some potions, this will only backfire, and occasionally wash the mouse pad, you can, because the wash will be more degumming.

- Q: How is rubber made? What kind of equipment do you need? How much is it?

- Machining process:This process involves basic processes such as plasticization, mixing, calendering or extrusion, forming and vulcanizing. Each process has different requirements for the product and cooperates with a number of auxiliary operations. In order to make all the necessary coordination agent in rubber, rubber Plasticating must first go through improving the plastic; then by mixing carbon black and all kinds of rubber and rubber additives are evenly mixed into rubber; rubber shaped blank after extruding; and then the textile materials and rolled hanging glue or glue (or metal material) together formed into semi-finished products; finally after vulcanization will have final semi-finished products made of high elastic plastic. The products with higher precision requirements, such as oil seals, O rings and seals, also need trimming and deburring, and manual trimming, mechanical trimming and cold trimming can be used.

- Q: What is the difference between natural and synthetic rubber?

- Natural rubber is mainly derived from the Hevea tree. When the epidermis of this rubber tree is cut open, it will shed milky juice. It is called latex, and the latex will be natural rubber when it is condensed, washed, molded and dried.

- Q: What kinds of vulcanized rubber do you have?

- According to the sources and methods of raw materials: rubber can be divided into two categories: natural rubber and synthetic rubber. Among them, the consumption of natural rubber accounted for 1/3, and the consumption of synthetic rubber accounted for 2/3.

- Q: What is the relationship between the hardness and tensile strength of rubber pad?

- The molecular weight increases, increasing the fan Edward force, the chain segment is not easy to slip, the equivalent of molecules formed between physical crosslinking points with the molecular weight increased, the tensile strength increased to a certain extent reached equilibrium; the microstructure of the molecule, such as the effect of CIS and trans type structure; crystallization and orientation.

- Q: What is rubber good for making weapons?

- Rubber is needed for vehicles, tires, rubber boats, clothing, shoes, medical devices, etc.

- Q: What are the causes of the rubber products breach?

- Measures to prevent aging: from the point of view of aging, one of the main reasons is the polymer structure itself. Therefore, it is important to improve the structure of polymers to improve their aging ability. For example, in rubber vulcanization, there are still unsaturated double bonds, and rubber products in use and it is difficult to avoid the erosion of sunlight, oxygen, ozone, so people on the synthesis of new varieties, to avoid or reduce the polymer chain of rubber double bonds, such as ethylene and propylene two monomer by copolymerization made two yuan B two rubber, different from other synthetic rubber is one of the major characteristics in the structure of the backbone is not completely saturated with double bond, making it the most ozone resistance, chemical resistance, high temperature resistant rubber aging; there is a kind of antioxidant, such as adding oxygen or ozone to prevent aging caused by antioxidants. Add UV stabilizers, heat stabilizers, preservatives and other unfavorable factors, and caused by aging.

Send your message to us

Concrete Pipeline DN150 Cleaning Ball And Column

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords