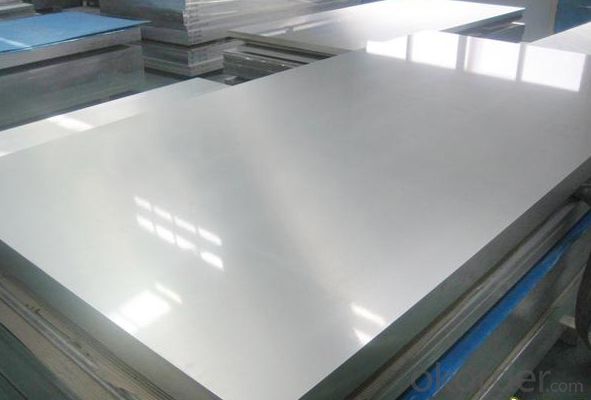

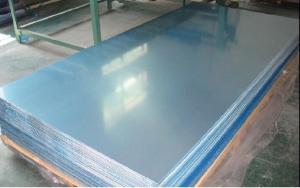

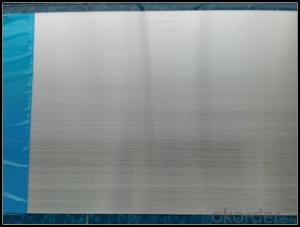

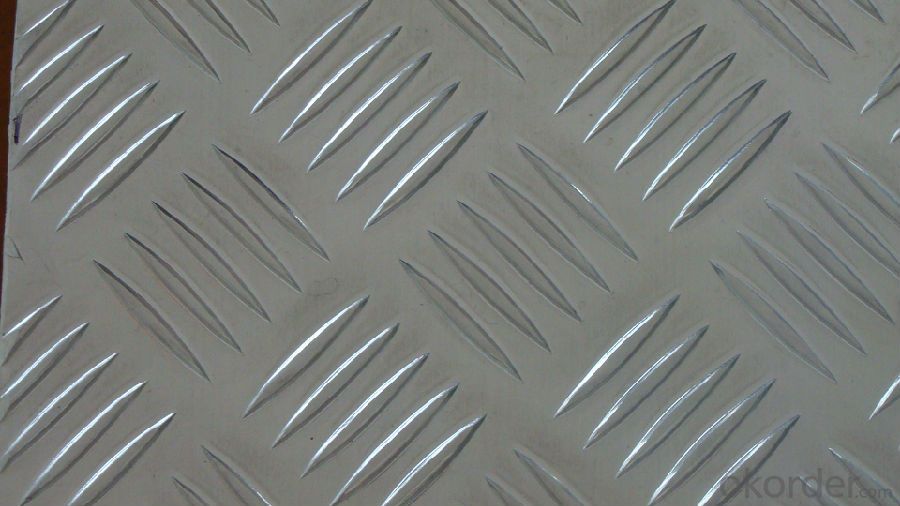

Composite Aluminum Sheets in San Diego - Brushed Aluminum Sheet 2mm Thick and Other Standard Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Discription:

Aluminum Sheets

Alloy No.: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5083, 5754, 8011, 8006, 8079, etc..

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm - 2100mm

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: why could aluminum pot be repaired by knocking the aluminum sheet into the pot but not being bonded by glue?

- the oxidation rate of aluminum's surface is very quick, so we cann't use the method of tin welding, and the cost of argon arc welding is very high,so aluminum pot's repair usually uses riveting. aluminum has low hardness and good ductility, so it can be repaired by tightly knocking, without the bonding of glue. general glue will decomposed in open fire, if we bond pot by glue, the pot after repair won't be able to endure high temperature.

- Q: the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- Q: i want to a material which is similar in properties like aluminium which has similar casting properties and easily available.

- It depends on what properties you are interested in. If you want specific answers, you need to ask specific questions. The previous answerers are not very well informed... There are, in fact, many excellent Al based casting alloys. And... cast alloys of brass, pot metal, lead, etc are not very similar to Al (but, again, it depends on specifically what properties you want). Consult your friendly neighborhood metallurgist but think about exactly what characteristics you need to have. The more completely you can define your requirements, the better someone can advise you on the pros and cons of different material selections.

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: Is it suitable to use aluminum windows in areas with cold weather conditions?

- <p>Yes, you can use aluminum windows in cold climates, but there are considerations. Aluminum is a good conductor of heat, which can lead to heat loss in cold weather. To mitigate this, insulated glass units and thermally broken frames can be used. These designs slow down heat transfer, making aluminum windows more energy-efficient in cold climates. Additionally, proper sealing and weatherstripping are crucial to prevent drafts and ensure the windows perform well in low temperatures.</p>

- Q: Do aluminum cans melt in typical campfires? I know the melting point is about 660 Celsius but do campfires get that high? I thought it would just be that the can becomes disfigured and collapses due to the heat, not due to it melting. Even if it did melt in the fire how would you find the remains? The can in a liquid form would certainly not be confined to one part of the fire and therefore wouldn't solidify in a small pool to see if it had melted or not. Any ideas?

- Campfires would not get that hot. However, even if they were hot enought, the aluminum in the can would not melt. It would oxidize before it had a chance to and turn into a white powder that migles among the ashes.

- Q: How does the price of 101 aluminum sheets compare to other aluminum alloys?

- The cost of 101 aluminum sheets may fluctuate based on various factors like market conditions, demand, and supply. Nonetheless, in general, 101 aluminum alloy is regarded as one of the more affordable choices among aluminum alloys. It is a popular option due to its relatively low price and satisfactory overall performance. When compared to other aluminum alloys, particularly high-strength alloys like 7075 or 6061, 101 aluminum sheets tend to be less expensive. This is because 101 aluminum is a relatively uncomplicated alloy with a lower content of alloying elements, resulting in lower production costs. However, it is important to note that the price difference between aluminum alloys can vary depending on current market conditions and specific requirements. Factors such as sheet thickness, size, and quantity can also impact the final price. Therefore, it is always advisable to consult suppliers or manufacturers to obtain the most accurate and up-to-date pricing information for 101 aluminum sheets in comparison to other aluminum alloys.

- Q: How do aluminum sheets perform in terms of formability?

- Aluminum sheets possess remarkable formability, renowned for their capability to be effortlessly molded and contoured into intricate configurations without encountering any cracks or fractures. The exceptional ductility and malleability of aluminum enable its transformation into diverse shapes, curves, and angles with relative simplicity. This inherent formability renders aluminum sheets highly adaptable for utilization in an array of applications, including automotive body panels, aircraft components, and architectural structures. Moreover, aluminum sheets exhibit commendable resistance to corrosion, further augmenting their performance in various environmental conditions. All in all, aluminum sheets amalgamate formability, strength, and durability, rendering them a favored choice across numerous industries.

- Q: This question asks for a list of various types of aluminum profiles that are typically used in conjunction with aluminum sheets.

- <p>Aluminum profiles are extruded shapes commonly used with aluminum sheets for various applications. The different types include: 1. Angle profiles, which are used for corners and edges. 2. Channel profiles, suitable for creating channels or frames. 3. T-slot profiles, ideal for modular systems requiring adjustable components. 4. U-channel profiles, used for covering edges and creating frames. 5. H-profiles, often used in structural applications. 6. Flat bar profiles, used for simple straight edges. 7. Round and square tube profiles, used for structural support and design elements. 8. Special profiles, which are custom-made for specific applications. These profiles are chosen based on the structural needs and design requirements of the project.</p>

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

Send your message to us

Composite Aluminum Sheets in San Diego - Brushed Aluminum Sheet 2mm Thick and Other Standard Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords