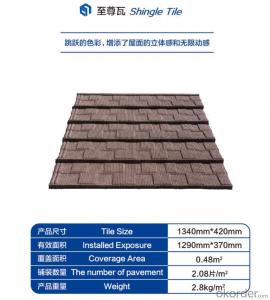

Black Aluminum Sheets - Color Stone Coated Roofing Shingles / Aluminum Zinc Steel Roof Tiles / Sand Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

- Q: How are aluminum sheets tested for quality and compliance with industry standards?

- Quality and compliance with industry standards for aluminum sheets are ensured through a comprehensive range of tests and inspections. These tests guarantee that the desired specifications and performance criteria are met by the sheets. Visual inspection is one of the commonly utilized tests, where the sheets are thoroughly examined for any surface defects like scratches, dents, or cracks. This examination is crucial to ensure a flawless and smooth appearance. Furthermore, dimensional checks are carried out to verify the thickness, width, and length of the sheets. Precise measurements are essential to meet the specific requirements of the intended application. Various tests are conducted to evaluate the mechanical properties. Tensile strength tests assess the maximum load the aluminum sheet can bear before breaking. This aids in determining the structural integrity of the sheet and its ability to withstand external forces. Similarly, hardness tests measure the sheet's resistance to indentation or penetration, providing insights into its durability and resistance to wear. Chemical composition analysis is also undertaken to ensure that the aluminum sheets contain the necessary alloying elements within the specified limits. This analysis helps confirm that the material composition aligns with industry standards, as different alloy compositions can affect the mechanical properties of the sheets and their suitability for various applications. Corrosion resistance tests assess the sheet's capacity to withstand environmental factors like moisture, chemicals, and temperature variations, thereby evaluating its surface integrity. This evaluation is particularly important for applications where aluminum sheets are exposed to corrosive substances or harsh environments. In addition to these tests, non-destructive testing techniques such as ultrasonic testing or eddy current testing may be employed on aluminum sheets. These methods help identify internal defects or irregularities that may not be visible through visual inspection alone. Overall, a combination of visual inspections, dimensional checks, mechanical tests, chemical composition analysis, and surface integrity evaluations are utilized to ensure that aluminum sheets meet the quality standards and compliance requirements set by the industry. These rigorous testing procedures guarantee that the sheets are suitable for their intended purpose and fulfill the expectations of customers.

- Q: Can aluminum sheets be easily shaped or bent into desired forms?

- Yes, aluminum sheets can be easily shaped or bent into desired forms. Aluminum is a highly malleable metal, which means it can be easily manipulated without breaking or cracking. Its low density and high strength-to-weight ratio make it an ideal choice for various applications where shaping or bending is required. Aluminum sheets can be shaped or bent using a variety of methods, including press-braking, roll-forming, or using specialized tools such as a sheet metal brake. The ease of shaping or bending aluminum sheets also makes it a popular choice for industries such as automotive, aerospace, construction, and manufacturing, where customized forms and designs are often needed.

- Q: What are the applications of aluminum sheets?

- The unique properties and versatility of aluminum sheets make them applicable in a wide range of industries. Some common uses for aluminum sheets include: 1. Construction: Aluminum sheets are utilized in various construction applications such as roofing, siding, gutters, and facades. They offer exceptional durability, resistance to corrosion, and the ability to withstand extreme weather conditions. 2. Transportation: The transportation industry extensively employs aluminum sheets, particularly in the manufacturing of automobiles, airplanes, trains, and ships. Their lightweight nature helps reduce fuel consumption, improve vehicle performance, and maintain strength and durability. 3. Packaging: Aluminum sheets are widely used in the food and beverage industry for packaging purposes. They are used in the production of cans, foils, and containers due to their ability to protect the contents from light, moisture, air, and bacteria. 4. Electronics: Aluminum sheets play a role in the production of electronic devices like laptops, smartphones, and tablets. Their excellent thermal conductivity properties make them ideal for heat dissipation, ensuring the longevity and performance of electronic components. 5. Industrial applications: Aluminum sheets find applications in various industrial sectors, including aerospace, marine, chemical, and energy. They are used to manufacture heat exchangers, tanks, pipes, and other equipment due to their corrosion resistance and high strength-to-weight ratio. 6. Decorative purposes: Aluminum sheets are also used for decorative purposes in architecture and interior design. They can be easily shaped, colored, and textured to create attractive facades, wall panels, ceilings, and furniture. 7. Reflective surfaces: Aluminum sheets are commonly employed for their reflective properties. They are used in mirrors, solar panels, light fixtures, and reflective signage to enhance brightness and improve energy efficiency. In conclusion, the exceptional properties of aluminum sheets make them widely applicable in various industries. Their lightweight nature, durability, resistance to corrosion, and thermal conductivity make them the preferred choice for construction, transportation, packaging, electronics, industrial applications, decoration, and reflective surfaces.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into dilute sulphuric acid?

- Because there is oxide on the surface of aluminum, the reaction will be quicker after polishing the oxide with abrasive paper.

- Q: Is it possible to use aluminum sheets for creating roofing tiles?

- <p>Yes, you can use aluminum sheets to make roofing tiles. Aluminum is a popular material for roofing due to its durability, lightweight, and resistance to corrosion. It can be shaped into various styles and sizes to mimic traditional roofing materials like clay or slate. Aluminum roofing tiles are also known for their energy efficiency, as they reflect heat and can help reduce cooling costs. However, it's important to ensure that the aluminum sheets are of good quality and installed correctly to achieve the desired performance and longevity.</p>

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- www.okorder /.. its doesnt burn burn u knw.it just becomes sorta britte.it becomes oxidised...u can got more infro there.try..i read it just now

- Q: Are aluminum sheets suitable for electronics applications?

- Yes, aluminum sheets are suitable for electronics applications. Aluminum is lightweight, highly conductive, and has good thermal properties, making it an ideal material for various electronic components such as heat sinks, enclosures, and printed circuit boards. Additionally, aluminum is corrosion-resistant and cost-effective, making it a popular choice in the electronics industry.

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is lightweight, strong, and has excellent corrosion resistance, making it an ideal material for various automotive components such as body panels, hoods, doors, and engine parts.

- Q: What are the different types of alloys used in aluminum sheet?

- Aluminum sheet incorporates a variety of alloys with distinct characteristics. Some of the most frequently employed alloys include: 1. The 3003 alloy is renowned for its exceptional corrosion resistance and finds utility in situations where moisture exposure is a concern. It is also highly malleable and can be easily welded, making it a popular choice for various structural components. 2. The 5052 alloy boasts remarkable corrosion resistance and excellent formability. It is commonly used in marine and automotive applications, as well as architectural elements. 3. The 6061 alloy provides unparalleled strength and is widely utilized in applications demanding high structural integrity. It is commonly found in the aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. The 7075 alloy is celebrated for its exceptional strength-to-weight ratio and is extensively employed in aerospace and defense applications. Furthermore, it is utilized in the manufacture of bicycle frames, rock climbing equipment, and other high-performance applications. 5. The 2024 alloy is renowned for its strength and outstanding fatigue resistance. It is frequently utilized in aerospace applications, as well as in the production of structural components and fasteners. These aforementioned examples merely scratch the surface of the multitude of alloys used in aluminum sheet. Each alloy possesses its own unique properties and advantages, rendering it suitable for specific industries and applications.

- Q: What is the typical fatigue life of aluminum sheets?

- The typical fatigue life of aluminum sheets can vary depending on several factors such as the alloy used, sheet thickness, manufacturing process, and the specific application it is being used for. Generally, aluminum sheets have a relatively high fatigue strength compared to other materials, allowing them to withstand a large number of cyclic loading cycles before failure. However, it is important to note that fatigue life can be influenced by various factors such as stress levels, loading conditions, and environmental factors like temperature and humidity. Aluminum sheets may experience a decrease in fatigue life when subjected to high stress levels, cyclic loading, or harsh environmental conditions. In certain applications where aluminum sheets are subjected to low stress levels or are not exposed to cyclic loading, they can have an infinite fatigue life. On the other hand, in high-stress applications or when subjected to cyclic loading, aluminum sheets typically have a finite fatigue life that can range from thousands to millions of cycles. To determine the precise fatigue life of aluminum sheets for a specific application, it is recommended to refer to relevant industry standards, test data, or consult with material engineers or manufacturers who can provide more accurate information based on the specific parameters and conditions of use.

Send your message to us

Black Aluminum Sheets - Color Stone Coated Roofing Shingles / Aluminum Zinc Steel Roof Tiles / Sand Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords