Color Roofing Sheets/Al-Zn Galvanized Steel Coil/PPGI in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Application of Color Roofing Sheets:

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

2.Features Color Roofing Sheets:

.Uses hot dip galvanized steel sheet as the base material

.Zinc layer protection, dope on the zinc layer can cover and protect the steel base from corrosion

.Good dilvery and competitive price, acceptable payment terms for LC or DP.

.We have stictly qualtiy controll system to assure the quality of all our products, our quality control system dot let any materials do shipment if the quality is not qualified.

3.Surface Finish of Color Roofing Sheets:

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

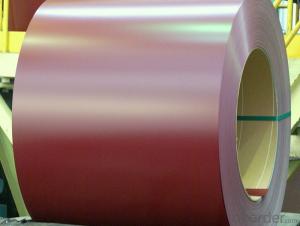

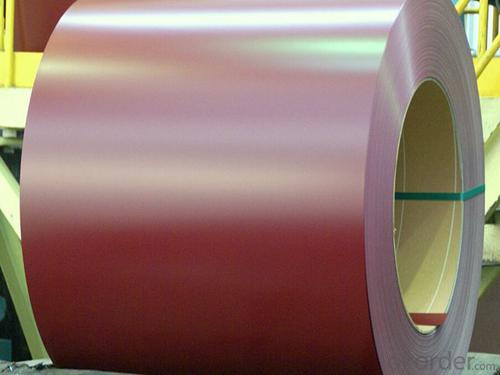

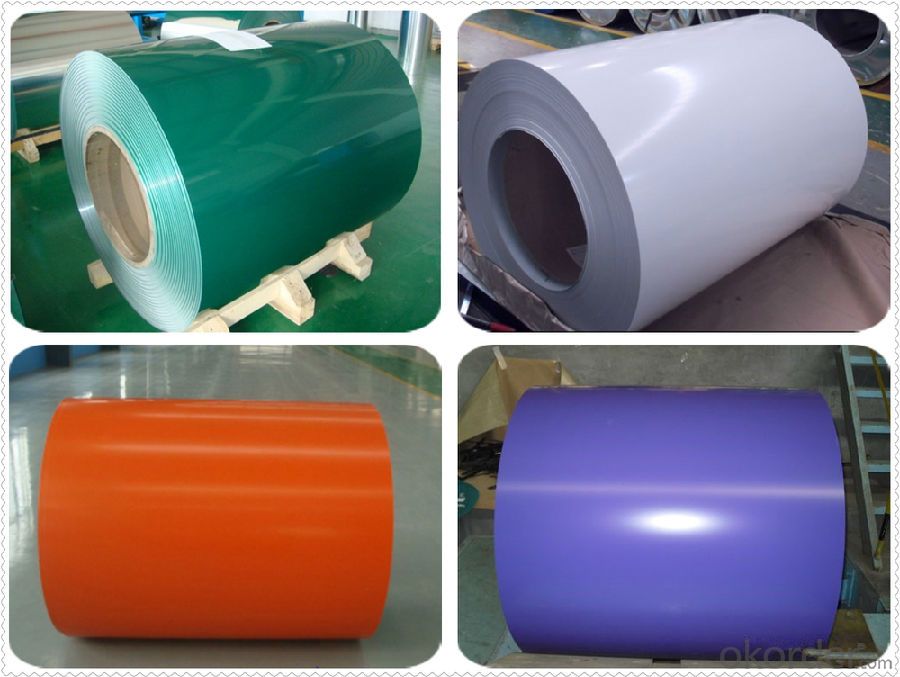

4.Color Roofing Sheets image:

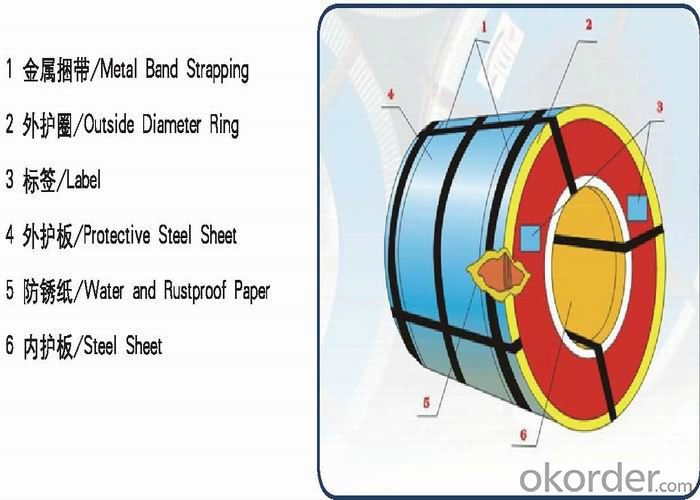

5.Packaging:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry for various applications such as manufacturing aircraft components, structural parts, and engine components.

- Q: Is steel easier to weld?Which is more brittle/less flexible?

- You should not attempt to do any traditional welding of steel to aluminum as they can form a hard and brittle inter metallic compound known as iron aluminide. You would have to employ a process that did not melt either species. Cladding could be an option but you are kind of limited to flat products that are sandwiched together. There is also explosive which does almost the same thing as cladding. Friction stir welding might be possible but I cant vouch for that. The temperature does get pretty hot, so I am not sure what would happen. But any of these suggestions would take specialized equipment not available to the average user. For weight, Al is 2.7 g/cc and Iron is about 7.8 so it is about 3 times heavier for the same volume. How strong either of them are greatly depends on specific alloys and heat treatment. I think some of the strongest aluminum alloys have a yield strength of about 50,000 psi which would relate to a relatively weak steel. For steel, there are alloys that can have yield strengths in the hundreds of thousands psi.

- Q: How are steel coils used in the production of automotive exhaust systems?

- Steel coils are used in the production of automotive exhaust systems as they are shaped and formed into various components such as pipes, mufflers, and catalytic converters. These coils are cut, bent, and welded to create the necessary shapes and sizes required for efficient exhaust flow and noise reduction. Additionally, the strength and durability of steel make it an ideal material for withstanding high temperatures and harsh conditions that exhaust systems endure.

- Q: What are the common applications of pre-painted galvanized steel coils?

- Pre-painted galvanized steel coils have a wide range of applications across various industries. Some of the common applications include: 1. Construction: Pre-painted galvanized steel coils are extensively used in the construction industry for roofing, wall cladding, and structural components. The coating on these coils provides excellent corrosion resistance and durability, making them suitable for both residential and commercial buildings. 2. Automotive: These coils are also widely used in the automotive industry for manufacturing parts and components such as body panels, interior trims, and underbody protection. The pre-painted coating enhances the aesthetic appeal of the vehicles while providing protection against rust and corrosion. 3. Appliances: Pre-painted galvanized steel coils are commonly used in the production of home appliances such as refrigerators, ovens, washing machines, and air conditioners. The smooth and durable coating on these coils ensures a long-lasting and visually appealing finish for the appliances. 4. Furniture: The pre-painted galvanized steel coils find application in the furniture industry for manufacturing cabinets, shelves, and other furniture components. The coating on these coils adds a decorative touch to the furniture while offering protection against scratches and wear. 5. Electrical and Electronics: These coils are utilized in the electrical and electronics industry for manufacturing switchboards, control panels, and enclosures. The pre-painted coating provides insulation and protection against electrical hazards, making them suitable for such applications. 6. Agricultural Equipment: Pre-painted galvanized steel coils are also used in the agricultural sector for manufacturing equipment like grain silos, livestock shelters, and poultry houses. The corrosion-resistant coating on these coils ensures the durability and longevity of the agricultural structures. 7. Signage and Advertisement: The vibrant and visually appealing colors of pre-painted galvanized steel coils make them a popular choice for signage and advertisement boards. The coated surface provides a smooth and glossy finish that enhances the visibility and attractiveness of the signage. In summary, the common applications of pre-painted galvanized steel coils include construction, automotive, appliances, furniture, electrical and electronics, agricultural equipment, and signage and advertisement. These coils offer excellent corrosion resistance, durability, and aesthetic appeal, making them suitable for a wide range of industries and applications.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear slitting, loop slitting, and single-knife slitting.

- Q: What are the characteristics of hot-rolled steel coils and cold rolled steel coils? What loading and unloading tools should be used? What items should be paid attention to?

- When placing materials to roll on both sides of the main pad wood pallets, prevent rolling back and forth. In addition the floor should be thickened, cannot have uneven or debris, because the line of steel coils when gravity concentrated in contact with the ground floor, there is a fracture easily, debris, easy to leave the indentation in the steel roll.

- Q: What are the common coil inspection techniques?

- Common coil inspection techniques include visual inspection, magnetic particle inspection, eddy current testing, ultrasonic testing, and radiographic testing.

- Q: Can steel coils be used in electrical applications?

- Certainly, electrical applications can make use of steel coils. In the realm of electrical circuits, steel coils often serve as magnetic cores in transformers and inductors, which are indispensable components. The steel employed in these coils typically consists of high-quality electrical steel, possessing distinct magnetic attributes, including low core losses and high permeability. These attributes empower the steel coils to efficiently transmit electrical energy between various circuit components. Furthermore, steel coils can also find utility in other electrical applications, such as the construction of electric motors and generators. Taking everything into account, steel coils are extensively employed in electrical applications due to their magnetic properties and their capacity to handle high currents and temperatures.

- Q: How are steel tape measures installed?

- The spring piece is fixed on the shaft, the other end is connected with the measuring tape core, fixed tape shell with a shaft, the spring plate and a circle around the axis of the ruler core, wrapped after the ruler core extends from the outer end of the incision length of the shell, gently pull, the spring is tightened, the pull out the part from the incision and then removed around the shaft, then gently pull out, and then put the ruler core tied to the shaft, removed from the incision so repeatedly, until the spring to put all the ruler core recovery. Then a cotter pin on the central shaft installed on the lid, will tighten the screws.

- Q: What is the current value of steel? Is it expected to increase in value?

- The steel in steel cents is the same as the steel in soup cans you throw out all the time. There is no sense in holding steel cents for their value as scrap. There are way too many steel cents around for them to ever have much numismatic value.

Send your message to us

Color Roofing Sheets/Al-Zn Galvanized Steel Coil/PPGI in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords