Goodman Aluminum Coils - Color Coating Aluminum Coil 1050 3003 for Curtain Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

Name | 3003 Aluminum Coil |

Brand | CNBM |

Alloy | 1100H-18, 3003-H24,3003-H26,3005-H26,8011,3004,3105,5005,etc. |

Thickness | 0.1~1.5mm |

Width | <2000mm< span=""> |

MOQ | 1 MT |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 1MT - 2MT |

2. Application of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

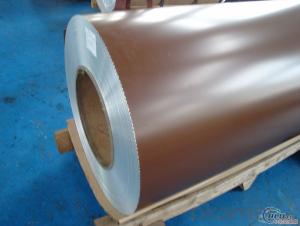

5. Image of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

6. Package and shipping of Color Coating Aluminium Coil 1050 3003 for Curtain Wall Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils contribute to energy-efficient windows and doors?

- Aluminum coils contribute to energy-efficient windows and doors by providing excellent thermal conductivity and allowing for better insulation. The coils are typically used to create frames for windows and doors, and their high thermal conductivity helps to transfer heat or cold more effectively. This allows for improved energy efficiency as the frames can effectively trap heat inside during winters and prevent heat from entering during summers, reducing the need for excessive heating or cooling. Additionally, aluminum coils are durable and low-maintenance, making them a sustainable and long-lasting choice for energy-efficient windows and doors.

- Q: What are the potential applications of painted aluminum coils?

- Painted aluminum coils possess a broad range of potential applications, thanks to their durability, versatility, and aesthetic appeal. The construction industry, for instance, frequently utilizes painted aluminum coils for roofing and siding materials. By providing protection against corrosion, UV rays, and harsh weather conditions, the painted coating enhances the longevity of the aluminum. Moreover, painted aluminum coils find use in the manufacturing of transportation vehicles. Due to aluminum's lightweight nature, it serves as an ideal material for automotive parts like body panels and trim. The painted coating not only improves the vehicle's appearance but also safeguards it against scratches and dents. Another potential application of painted aluminum coils lies in the production of household appliances. The painted coating imparts a distinct finish to appliances such as refrigerators, ovens, and washing machines, increasing their visual appeal. Additionally, the protective layer helps prevent damage from everyday use, thus extending the lifespan of the appliances. Furthermore, the signage industry benefits from painted aluminum coils. These coils can be adorned with vibrant colors and designs, making them suitable for creating attention-grabbing signs and billboards. Their durable painted coating ensures that the signage remains vibrant and intact even when exposed to outdoor environments. In the furniture industry, painted aluminum coils can be utilized to manufacture various pieces like chairs, tables, and cabinets. Aluminum's lightweight quality makes the furniture easy to move and transport, while the painted coating adds a stylish and contemporary touch to the designs. Overall, painted aluminum coils offer immense potential across diverse industries, ranging from construction and automotive to appliances, signage, and furniture. Their combination of durability, versatility, and aesthetic appeal has established painted aluminum coils as a popular choice in various sectors.

- Q: What is the difference between pre-painted and natural aluminum coils?

- Pre-painted and natural aluminum coils refer to two different types of aluminum coils used in various industries. The main difference between pre-painted and natural aluminum coils lies in their surface finish. Pre-painted aluminum coils, as the name suggests, are coated with a layer of paint or a protective coating before they are delivered to the customers. This coating is applied in a controlled environment, ensuring a uniform and durable finish. The pre-painted coating provides several advantages such as enhanced corrosion resistance, improved aesthetics, and better weatherability. It also allows for a wide range of color options, making it suitable for architectural applications where color matching is important. On the other hand, natural aluminum coils are left untreated and retain their original metallic appearance. These coils are typically used in applications where the natural aluminum finish is desirable, such as in the manufacturing of consumer electronics, automotive parts, and other industrial products. Natural aluminum coils are known for their excellent thermal conductivity, lightweight nature, and high strength-to-weight ratio. In summary, the difference between pre-painted and natural aluminum coils lies in their surface finish. Pre-painted aluminum coils are coated with a protective layer of paint, offering enhanced corrosion resistance, improved aesthetics, and color options. Natural aluminum coils, on the other hand, retain their original metallic appearance and are often used in applications where the natural aluminum finish is preferred.

- Q: What is the formula to calculate the wall thickness of aluminum coil?

- Aluminum coil thickness*aluminum coil width*aluminum coil curl*aluminum density (the density of aluminum alloy: 2.73, the density of pure aluminum: 2.71)

- Q: the ingredient on the back says aluminum?also ..what is sodium benzoate?Is all this stuff that terrible for you? Or does it mean something else?

- The aluminum is in the baking powder. Very common but you can buy it without it, it is much healthier for you. Aluminum is correlated to Alzheimer's and ADD. Baked goods taste much better without the aluminum too. Benzoate of soda, a preservative that can alter your DNA. Not too good for you, no matter what the FDA may say about it. All told, if you are concerned for your health, keep to organic as much as possible and made from scratch too. Way too much junk is put in our food and health products.

- Q: Can aluminum coils be used in the manufacturing of beverage cans?

- Yes, aluminum coils can be used in the manufacturing of beverage cans. Aluminum is a commonly used material for manufacturing beverage cans due to its various advantages. Aluminum coils are typically rolled into thin sheets, which are then cut, formed, and coated to create the final can shape. These coils provide a lightweight, durable, and corrosion-resistant material that is suitable for storing and preserving beverages. Additionally, aluminum is a highly recyclable material, making it an environmentally friendly choice for beverage can production.

- Q: What are some common applications for aluminum coils?

- Due to their exceptional qualities and versatility, aluminum coils find widespread use in various industries. They are particularly utilized in: 1. Construction: The construction industry extensively employs aluminum coils for roofing, cladding, and insulation purposes. Their lightweight nature makes them ideal for reducing overall structure weight and providing excellent corrosion resistance. 2. Transportation: The automotive and aerospace industries widely utilize aluminum coils. In the automotive sector, they are employed in the manufacturing of heat exchangers, radiators, and condensers, as well as lightweight body panels, improving fuel efficiency. In the aerospace industry, aluminum coils are used to manufacture aircraft parts with a high strength-to-weight ratio, such as wings, fuselages, and engine components. 3. Electrical and Electronics: The electrical and electronics industry employs aluminum coils in various applications. They are commonly used in the production of transformers, motors, and generators due to their excellent conductivity and lightweight nature. Aluminum coils also find use in electrical cable manufacturing, as they offer good electrical conductivity and resistance to corrosion. 4. Packaging: The packaging industry extensively uses aluminum coils due to their excellent barrier properties. They are commonly employed for packaging food and beverages, pharmaceuticals, and other consumer products. Aluminum coils provide an impermeable barrier against moisture, oxygen, and light, ensuring the preservation and protection of packaged goods. 5. Heating, Ventilation, and Air Conditioning (HVAC): Aluminum coils are widely integrated into HVAC systems for their excellent heat transfer properties. They are commonly found in air conditioning systems, heat pumps, and refrigeration units. Aluminum coils facilitate efficient heat exchange, ensuring effective cooling and heating processes. In conclusion, aluminum coils are widely employed in the construction, transportation, electrical and electronics, packaging, and HVAC industries. Their lightweight nature, corrosion resistance, excellent conductivity, and heat transfer properties make them highly versatile and valuable in these sectors.

- Q: Can aluminum coils be used for electrical enclosures?

- Yes, aluminum coils can be used for electrical enclosures. Aluminum is a commonly used material for enclosures due to its excellent conductivity, lightweight nature, and resistance to corrosion. It provides good protection against electromagnetic interference and can effectively dissipate heat. Additionally, aluminum coils can be easily formed and fabricated into various shapes and sizes, making them suitable for electrical enclosures in different applications.

- Q: What are the electrical conductivity properties of aluminum coils?

- Aluminum coils have excellent electrical conductivity properties. Aluminum is a highly conductive metal, second only to copper. It possesses low resistivity and can effectively carry electrical current, making it a preferred choice for various electrical applications such as power transmission, wiring, and electrical coil windings.

- Q: Can aluminum coils be embossed or textured?

- Aluminum coils possess the capability to undergo embossing or texturing, thereby enabling the creation of patterns or designs on their surface. This can be achieved through mechanical or chemical processes. The resulting embossed or textured surface not only enhances the visual appeal but also improves the functionality of the aluminum coil, by augmenting its grip or minimizing glare. Consequently, these aluminum coils, with their embossed or textured features, have found widespread utilization across industries like construction, automotive, and packaging.

Send your message to us

Goodman Aluminum Coils - Color Coating Aluminum Coil 1050 3003 for Curtain Wall Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords