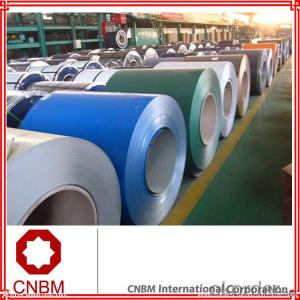

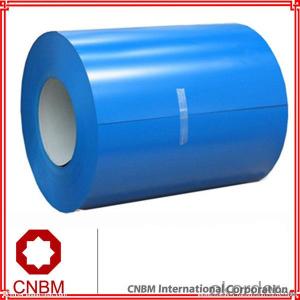

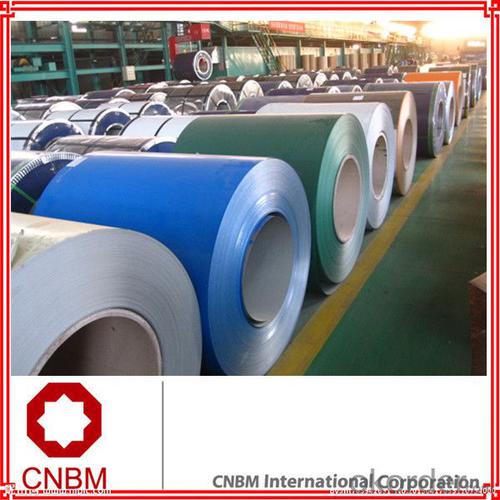

Color coated steel coil base material GL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 31234 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Brief of Product

Product Features

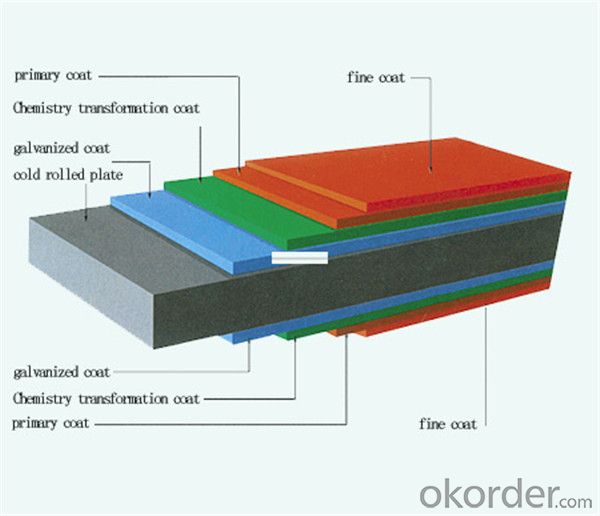

1 Extending service life of products:

Color coating is for protecting steel substrate and for promoting corrosion control effects. Subject to the environment, the different coating combination promotes environmental resisting functions (such as heat resistance, corrosion resistance, humidity resistance, bending resistance, weathering resistance, impact resistance, acid / alkali resistance, chemical resistance and pollution resistance) to offer ultra durability.

2 Better forming ability:

Coating Layer has good bending ability and in high speed forming, it maintains good forming ability and would not cracking or peel off. The coating could be adjusted to meet for different substrate general use, drawing, deep drawing or lock forming, structural use and other purposes.

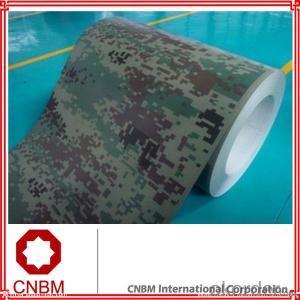

3 ariable colors:

With different glosses and colors, it displays beautiful appearance that allow for new product designs, diversified creative elements and higher living quality.

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

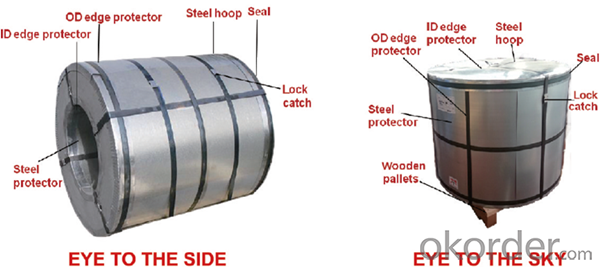

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our service:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: I recently got in a car accident with a steel mailbox, on a snowy day. I was wondering if i can do anything since the steel mailbox caused my car to be totaled. Otherwise it would have been fine and would have suffered only minor damage. Anything I can do here to maybe get some money back? Thanks!

- Let me get this straight. You were driving too fast for conditions, lost control due to driving too fast, hit a stationary mailbox, car is totaled due to driving too fast for conditions, and you want to be reimbursed? Sorry, you are dead wrong. It is your duty to maintain control of your car at all times. If there was any damage to the mailbox, you are the one liable.

- Q: Can steel coils be coated with luminescent materials?

- Yes, steel coils can be coated with luminescent materials.

- Q: How are steel coils tested for quality?

- Steel coils are tested for quality through a variety of methods including visual inspection, dimensional measurements, chemical composition analysis, and mechanical testing. These tests ensure that the steel coils meet the required standards for strength, durability, and other performance parameters.

- Q: How do steel coils contribute to the energy efficiency of buildings?

- Steel coils contribute to the energy efficiency of buildings in several ways. Firstly, steel coils are often used in the construction of roofs and walls, providing a durable and well-insulated structure that helps to minimize heat transfer and reduce energy loss. Additionally, steel coils can be coated with reflective materials, such as cool roof coatings, which help to reflect the sun's heat and reduce the cooling load on the building. Lastly, steel coils are also commonly used in the manufacturing of HVAC systems, ensuring efficient heating and cooling operations, further enhancing the energy efficiency of buildings.

- Q: Can steel coils be stamped?

- Yes, steel coils can be stamped. Stamping is a common process used to shape and form steel coils into various shapes and sizes for different industrial applications.

- Q: How are steel coils straightened?

- Steel coils are straightened using a process called leveling, which involves passing the coil through a series of rollers that apply pressure to gradually remove any bends or deformations in the steel.

- Q: What are the common coil defects and their causes?

- Common coil defects include: 1. Coil breaks: These are caused by improper handling, excessive tension, or defects in the raw material. They result in breaks or fractures in the coil. 2. Edge waves: Edge waves occur due to uneven tension during winding, improper coil alignment, or excessive elongation. This leads to wavy or uneven edges in the coil. 3. Buckling or wrinkling: Buckling or wrinkling can be caused by excessive elongation, improper winding tension, or uneven cooling. It results in irregularities or folds in the coil surface. 4. Slivers: Slivers are thin strips of material that can be present on the surface of the coil. They are typically caused by poor shearing or cutting processes, improper cleaning, or debris in the production line. 5. Oil spots: Oil spots are oily or greasy stains that can appear on the coil surface. They are usually caused by inadequate cleaning or lubrication during the manufacturing process. 6. Coating defects: Coating defects can include uneven or inconsistent coating, bubbles, or peeling. These defects can be caused by issues with the coating application process, improper drying or curing, or contamination in the coating material. It is important to address these coil defects promptly to ensure product quality and prevent further issues during subsequent processing or usage.

- Q: Cold rolled steel coil steel, what is the difference?

- Cold: hot rolled steel coil as raw material by pickling descaling after cold rolling, the finished rolling hard volumes, due to continuous deformation caused by cold hardening the volume rolling hard strength, hardness, toughness index rise decline, so the stamping performance will deteriorate, only for a simple deformation of parts. Rolled hard rolls can be used as raw material for hot galvanizing plants. Because the hot galvanizing units are equipped with annealing lines, the steel coils are rolled continuously at room temperature. Its strength is very high, but toughness, weldability is slightly worse, bright surface, not easy to corrosion, in order to prevent rust, the factory surface is coated with a protective layer of oil (hot rolling did not). Because of the complexity of the process, the price is higher.

- Q: What are the different methods of edge trimming for steel coils?

- There are several methods of edge trimming for steel coils, depending on the specific requirements and application. Some of the common methods include: 1. Slitting: This is one of the most common methods used to trim the edges of steel coils. It involves passing the coil through a set of circular knives that cut the edges into narrower strips. Slitting can be done in-line during the manufacturing process or as a separate operation. 2. Shearing: Shearing is another popular method used for edge trimming. It involves using a set of blades to cut the edges of the coil in a straight line. Shearing is often used when precise and clean cuts are required, and it can be done manually or with the help of automated machinery. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser to trim the edges of steel coils. This method provides precise and smooth cuts, and it is often used when high accuracy and quality are essential. Laser cutting can be incorporated into the production line or performed as a standalone process. 4. Grinding: Grinding is a method that involves using abrasive wheels or belts to remove material from the edges of steel coils. It is commonly used to remove burrs, rough edges, or surface imperfections. Grinding can be done manually or with the help of automated machines, depending on the scale and complexity of the trimming process. 5. Waterjet cutting: Waterjet cutting is a method that utilizes a high-pressure jet of water mixed with abrasive particles to trim the edges of steel coils. This method is known for its versatility and ability to cut through a wide range of materials and thicknesses. Waterjet cutting is typically used when complex shapes or intricate designs need to be achieved. Overall, the choice of edge trimming method for steel coils depends on factors such as the desired accuracy, speed, complexity of the edges, and the specific requirements of the application. Different methods offer varying levels of precision, efficiency, and cost-effectiveness, allowing manufacturers to select the most suitable technique for their specific needs.

- Q: What are the common coil handling challenges?

- Common coil handling challenges include the risk of coil damage during handling and transportation, difficulties in aligning and positioning coils accurately, issues with coil slippage and instability, as well as the need for specialized equipment to safely and efficiently handle large and heavy coils. Additionally, managing coil edges and preventing injuries to workers are also common challenges faced in coil handling processes.

Send your message to us

Color coated steel coil base material GL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 31234 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords