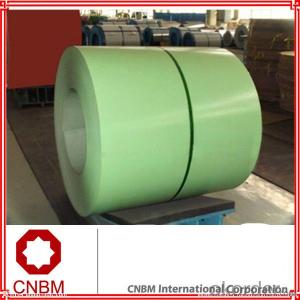

Color Coated Steel Coils Based on Gi Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Surface Treatment:Coated

Technique:Cold Rolled

Standard:JIS

Type:Steel Coil

Special Use:High-Strength Steel Plate

Application:Building Material, Roofing, Household Appliance, E

Export Markets:Global

Additional Info.

Packing:Standard Export and Seaworthy Packing

Standard:GB/T12754, JIS3312, EN 10169 ASTM A755

Origin:China

Product Description

Color coated Prepainted Galvanized Steel Coils

Grade: SGCC, DX51D, CGCC

Thick: 0.17-0.8, Width: 58-1250mm

Coat: PE, SMP, HDP, PVDF

PPGI PPGL Prepainted Steel coil:

Color coated Prepainted galvanized Steel Coils

Certificate: ISO 9001/14001

The main specification is as belows:

Standards: GB/T12754, JIS3312, EN 10169 ASTM A755

Thickness: 0.14-0.8mm; Width: 914-1250mm

Tolerance: +2/0mm, thickness tolerance: +0.02/-0.02mm (or according to customers' request).

Coating mass: Top; 13-25, Back: 5-10

Coil weight: 5-8 metric tons

Coil DM: I. D: Φ 508m/610mm O. D: Max Φ 1500mm

Coating type: PE, SMP, HDP, PVDF

Common performance of front coating:

(1). Thickness: ≥ 20μ M

(2). Pencil Hardness: 2H

(3). 60° Specular glossiness of coating: >60

(4). 180° Bend: ≤ 3T

(5). Impact: ≥ 9J

(6). Salt Fog Resistant: ≥ 500h

(7). Color difference: <3Δ E

Application :

1. Construction: (Outside) workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door

(Inside) door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter

2. Electrical appliance: Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker

3. Furniture: Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf

4. Carrying trade: Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board

5. Others: Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment

Specification:

| NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

| CERTIFICATE | ISO9001 | ||

| STANDARD | GB/T-12754 JIS G 3312 EN 10169 ASTM A755 | GB/T-2518 JIS G 3302 EN 10142/10427 ASTM A653 | GB/T-14798 JIS G 3321 EN 10215 ASTM A792 |

| GRADE | SGCC DX51D SGCH CGCD1-CGCD3 CGC340-CGC570 GRADE | SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

| MODEL NO | 0.16MM-1.0MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc |

| SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating | |

| APPLICATION | Structural use ,roofing, corrugated roofing, commercial use, household appliance, industry, family | ||

| SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: How are steel coils used in the production of marine vessels?

- Steel coils are used in the production of marine vessels primarily for their strength, durability, and corrosion resistance. These coils are shaped and formed into various components such as hulls, decks, and bulkheads, providing a sturdy framework for the entire vessel. By utilizing steel coils, marine vessels gain the necessary structural integrity to withstand harsh marine environments and ensure the safety and reliability of the vessels.

- Q: What is stainless steel coil used for?

- Stainless steel coil is primarily used in various industries for its durability, corrosion resistance, and aesthetic appeal. One of the most common applications is in the manufacturing and construction sectors, where stainless steel coils are utilized to produce a wide range of products such as kitchen appliances, cutlery, automotive parts, and architectural structures. The corrosion-resistant properties of stainless steel make it an ideal choice for applications that require resistance to moisture, chemicals, and harsh environmental conditions. Additionally, the high strength and heat resistance of stainless steel coils make them suitable for use in industrial equipment, heat exchangers, and piping systems. Moreover, the aesthetic appeal of stainless steel, with its sleek and modern appearance, is often preferred in the design and production of consumer goods, including furniture, jewelry, and decorative items. Overall, stainless steel coil is a versatile material that finds extensive usage across various industries due to its excellent mechanical properties, resistance to corrosion, and aesthetic versatility.

- Q: How are steel coils recycled?

- Steel coils can be recycled through a process that involves melting them down in a furnace, removing impurities, and then shaping the molten steel into new coils or other steel products. This recycling method helps conserve resources, reduce waste, and significantly cut down on energy consumption compared to producing steel from raw materials.

- Q: What are the advantages of using steel coils in construction?

- There are several advantages of using steel coils in construction. Firstly, steel coils offer exceptional strength and durability, making them suitable for supporting heavy loads and withstanding harsh environmental conditions. Additionally, steel coils provide a high degree of flexibility, allowing for customization and versatility in construction projects. Moreover, steel coils are fire-resistant and non-combustible, enhancing the safety of structures. Furthermore, they have excellent corrosion resistance, requiring minimal maintenance and ensuring long-term structural integrity. Lastly, steel coils are readily available and cost-effective, making them a preferred choice in the construction industry.

- Q: What is the size range of steel coils?

- The size range of steel coils can vary depending on the specific requirements and applications, but generally, they can range from a few inches to several feet in width and from a few thousand pounds to several tons in weight.

- Q: can steel boil and turn into a gaseous state?? if so how hot does it have to be for it to boil

- well what for yo? melting point of steel is 800 degrees, oxidation being 1400 degrees.

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through a process known as galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing the steel from coming into direct contact with moisture and oxygen, which are the main causes of corrosion. Additionally, other protective measures such as painting or coating the steel with anti-corrosion materials may also be employed to further enhance its resistance against corrosion.

- Q: the difference between the original steel and mild steel from percentage of carbon

- Carbon steel includes mild steel. Mild carbon steel(as it is referred to) contains .05 - .29% carbon. Medium carbon steel is from .30 - .59%. High carbon steel is from .60 - .99%. Ultra high carbon steel is from 1.00 - 2.00%. Steel is considered carbon steel up to 2.1%. Past that it is considered cast iron. The more carbon in the steel the harder and less ductile and maleable it is and also the more brittle it is. The less carbon in the steel more it will bend and shape without breaking. So in essence carbon adds strength but takes away from its elasticity. If you are interested in this subject an interesting source is swordmaking where hardness(carbon content) is crucial. The information behind this subject is pretty infinite.

- Q: and what are the four main elements in STAINLESS steel? x

- decreasing the carbon content fabric will strengthen the ductility, which will make it greater versatile. Carbon in metallic varieties brittle cementite (iron carbide) which will strengthen the hardness and capability of metallic.

- Q: On a fixie frame what should i get an aluminum frame or a steel frame

- I'm afraid you have opened a can o'worms. Aluminum as a material is roughly 1/2 the weight of steel. Aluminum as a material is also roughly 1/3 the strength of steel. his means you need 3 times more aluminum to make a frame as strong as steel which makes the aluminum frame 25% heavier. That being said, well designed and more expensive aluminum frames can easily weigh less than low zoot steel. Buying a cheap bike with an aluminum frame will ALWAYS weigh more than a middle of the road bike with a steel frame. ...and THAT being said, high end steel can easily weigh less than a high quality aluminum frame... note we are talking frames in the $2000 range- just for the frame. So, based on your explanation and attendant budget of the bikes you are considering, buy the steel bike. You won't be losing or gaining anything... except saving money.

Send your message to us

Color Coated Steel Coils Based on Gi Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords