Color Coated Pre-Painted Steel Coil or Steel Sheet in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

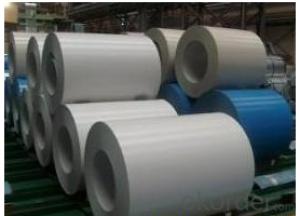

1.Structure of Color Coated GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Color Coated GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3. Color Coated GI/GL Steel Coil Images

4.Color Coated GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Color Coated GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I have heard using the BRASS casing is the best thing for an AR-15? Should i just use Brass or Steel?

- Many people have to jam a cleaning rod muzzle end first, using a hammer to bang out steel cased ammo out of an Ar rifle. This has happened to me 3 times and will Never happen again. It said its harder on the extractor, well that is not so but the case will be badly damaged by the extractor and I don't think that is a good thing for any extractor. Any individual pushing steel cased ammo must be selling it...Don't Buy It!!!

- Q: What are the common methods of packaging steel coils for transportation?

- There are several common methods of packaging steel coils for transportation. One widely used method is to use steel strapping or bands to secure the coils together. This method involves tightly wrapping the coils with steel bands and securing them with metal buckles or seals. The strapping helps to keep the coils in place and prevents them from shifting or rolling during transportation. Another common method is to use wooden pallets or skids to stack and transport the steel coils. The coils are placed on the pallets and secured with steel strapping or bands. This method provides stability and allows for easy handling and loading onto trucks or other transportation vehicles. Some steel coils are also packaged in wooden crates or boxes. These crates are typically made of strong and durable wood and are designed to protect the coils from external impacts or damage during transportation. The crates are often reinforced with steel bands or strapping to provide additional strength and stability. In addition to these methods, some steel coils are packaged in specialized containers or units. These containers are specifically designed to hold and secure steel coils for transportation. They often have built-in mechanisms or features that make loading and unloading the coils easier and safer. It is important to note that the specific method of packaging steel coils for transportation may vary depending on factors such as the size and weight of the coils, the mode of transportation, and any specific requirements or regulations in place.

- Q: How much does a steel coil weigh?

- The weight of a steel coil can vary depending on its dimensions and thickness. However, on average, a steel coil can weigh anywhere between 2 to 20 tons.

- Q: What are the common methods of protecting steel coils from corrosion?

- There are several common methods used to protect steel coils from corrosion. 1. Coating: One of the most effective methods is to apply a protective coating on the surface of the steel coil. Various types of coatings such as paint, epoxy, or zinc can be used to create a barrier between the steel and the corrosive environment. These coatings provide excellent corrosion resistance and prevent moisture and oxygen from reaching the steel surface. 2. Hot-dip galvanizing: This method involves immersing the steel coil in a bath of molten zinc, which creates a thick layer of zinc coating on the surface. The zinc coating acts as a sacrificial barrier, protecting the steel from corrosion. Hot-dip galvanizing is particularly effective in harsh environments or for long-term outdoor exposure. 3. VCI (Volatile Corrosion Inhibitor) packaging: VCI packaging is a method where steel coils are wrapped in a specially designed film or paper that contains volatile corrosion inhibitors. These inhibitors vaporize and form a protective layer on the surface of the steel, preventing corrosion. VCI packaging is commonly used for short-term storage or transportation of steel coils. 4. Desiccants: Moisture is a major contributor to corrosion. Therefore, using desiccants such as silica gel or activated alumina can help absorb moisture and maintain a dry environment around the steel coils. Desiccants are often used in conjunction with other protective methods to enhance corrosion protection. 5. Proper handling and storage: Proper handling and storage practices can significantly reduce the risk of corrosion. Steel coils should be stored in a dry environment away from moisture sources. They should also be handled with clean gloves to prevent the transfer of corrosive contaminants. Regular inspection and maintenance of the storage area are essential to identify and address any potential corrosion risks. By employing one or a combination of these methods, steel coils can be effectively protected from corrosion, ensuring their durability and integrity.

- Q: What are the common defects in steel coils?

- There are several common defects that can occur in steel coils during the manufacturing or handling processes. These defects can affect the quality and performance of the steel, and it is important to identify and address them to ensure the production of high-quality steel products. Some of the common defects in steel coils include: 1. Edge waves or buckles: This defect occurs when the edges of the steel coil become wavy or buckled. It can be caused by improper winding, uneven cooling, or excessive tension during the manufacturing process. Edge waves can lead to difficulties in further processing and affect the appearance of the final product. 2. Coil breaks: Coil breaks are longitudinal breaks or cracks that occur in the steel coil due to excessive strain or stress. These breaks can be caused by improper winding, uneven cooling, or excessive tension during the manufacturing process. Coil breaks can lead to product quality issues and are a major concern in the steel industry. 3. Surface defects: Surface defects in steel coils can include scratches, pits, or stains on the surface. These defects can be caused by improper handling, surface contamination, or inadequate cleaning processes. Surface defects can affect the appearance of the steel and may also lead to corrosion or other performance issues. 4. Slivers: Slivers are thin strips or flakes that can peel off from the edges of the steel coil. They can be caused by poor edge trimming, improper handling, or defects in the rolling mill. Slivers can cause difficulties in further processing and may also affect the surface quality of the final product. 5. Weld defects: In steel coils that are made by welding multiple strips together, weld defects can occur. These defects can include incomplete fusion, porosity, or cracks in the weld area. Weld defects can weaken the steel and affect its mechanical properties, making it unsuitable for certain applications. 6. Shape defects: Shape defects in steel coils can include camber, coil set, or crossbow. These defects can be caused by uneven cooling, improper winding, or tension variations during the manufacturing process. Shape defects can make it difficult to process the steel and may lead to dimensional inaccuracies in the final product. It is essential for manufacturers and users of steel coils to be aware of these common defects and take appropriate measures to prevent or mitigate them. Quality control measures, proper handling procedures, and regular inspections can help in identifying and addressing these defects to ensure the production and use of high-quality steel products.

- Q: How are steel coils used in the manufacturing of furniture?

- Steel coils are commonly used in the manufacturing of furniture as they provide structural support and stability. They are typically used in the construction of sofa frames, mattress foundations, and other furniture pieces that require strength and durability. The coils are often incorporated into the furniture's framework or used as a base for cushions and upholstery, ensuring long-lasting and comfortable products.

- Q: What are the different types of steel coil cutting blades?

- There are several different types of steel coil cutting blades, including shear blades, slitting blades, and rotary slitter knives. Shear blades are used for straight cuts and are typically made of high-speed steel or carbide. Slitting blades are designed for cutting coils into narrower strips and can be made of high-speed steel or tungsten carbide. Rotary slitter knives are used in rotary slitting machines and come in various configurations, such as circular or straight-edged blades, depending on the specific cutting requirements.

- Q: How do steel coils contribute to sound insulation in buildings?

- Steel coils can contribute to sound insulation in buildings due to their high density and ability to absorb and dampen sound waves. The compact arrangement of steel coils within walls or floors helps to reduce the transmission of sound, thus providing a barrier against noise and enhancing the overall acoustic performance of the building.

- Q: Are steel coils susceptible to damage during storage or transportation?

- Yes, steel coils are susceptible to damage during storage or transportation. Steel coils are often heavy and can be prone to deformation, bending, and scratching if mishandled. Additionally, improper stacking or securing during transportation can lead to shifting or movement of the coils, which can cause damage. Furthermore, exposure to moisture, extreme temperatures, or corrosive substances can also affect the integrity of the steel coils. Therefore, it is crucial to handle, store, and transport steel coils carefully to minimize the risk of damage and ensure their quality and usability.

- Q: How are steel coils used in the production of metal bridges?

- Steel coils are used in the production of metal bridges as they are rolled into the desired shape and size to form the structural components of the bridge, such as beams, girders, and support structures. These coils provide the necessary strength and durability to withstand the weight and stress of the bridge, ensuring its long-term stability and safety.

Send your message to us

Color Coated Pre-Painted Steel Coil or Steel Sheet in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords