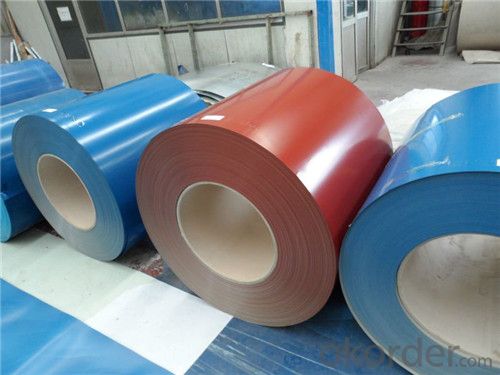

color Coated gAlvanized Cold rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications

Color Coated Steel Coil/PPGI/Prepainted Galvanized Steel Coils

Standard: JIS,ASTM,GB,DIN.

Technique: Hot dipped Cold-rolled PPGI

Nominal Thickness: 0.13mm-1.5mm

Nomina Width: 600mm-1250mm

Coil Weight: 3MT-8MT.

Zinc Coating: 40g-275g

Surface Finish: normal coated, embossed patterns, printed patterns

Color Coated Steel Coil/PPGI/Prepainted Galvanized Steel Coils :

1.Best price,high quality

2.12 years history

3.Special factory

3.ISO,SGS,BV

Feature OF ppgi steel coil /ppgi sheet :

1. The sheets excellent with weather resistance and color stability , long life span up to 25--40 years and 10 year free from color fading .

2. Decorative ability, bring the roof fantastic wavy look and multi-dimensional effect.

3. Good load-carrying ability and anti-impact resistance , the test show no crack happened after 1 kg steel ball drop from 3 meters on sheet.

4. Excellent corrosion resistance , free from corrosion of varoius chemical substances such as acid ,alkali and salt .

5. Heat insulation , the coefficient of heat conductivity is 0.325W/M.K, which is 1/310 of clay tile and 1/5 of cement tile , it can reduce cooling costs in your home or office .

6. Good fireproofing performance , according to GB8624-2006 fireproofing ≥class B.

7. excellent waterproof performance , no water absorb and seep.

8. Green and environment friendly , dont contain asbestos and any redioactive element , can be recycled.

9. Easy to install , 960mm effective width and customized length ensure fast installation .

10. Self-cleaning performance , it dont absorb dust and very easy clean by rain.

| Prepainted Galvanized Steel Sheet Grade | Chemical Composition % | Mechanic Property | ||||||

| C | Si | Mn | S | P | T.S | Y.S | E.L | |

| x103 | x103 | x102 | x103 | x103 | Mpa | Mpa | % | |

| JIS G3302 SGCC | 12 | 30 | 41 | 31 | 21 | 480 | 300 | 13 |

| JIS G3302 SGCH | 12 | 10 | 21 | 18 | 8 | 680 | 650 | |

| ASTM A653 CS.B | 20 | 30 | 60 | 35 | 30 | 386 | 205~380 | 20 |

| EN 10346 DX51D+Z | 29 | 21 | 18 | 1.8 | 11 | 355 | 245 | 38 |

| G550 | 20 | 6 | 73 | 5 | 17 | 715 | 654 | 8 |

- Q: How are steel coils used in the manufacturing of industrial compressors?

- Steel coils are used in the manufacturing of industrial compressors as they are shaped and formed into various components of the compressor, such as the casing, cylinder, and piston. The steel coils provide strength, durability, and stability to these components, allowing the compressor to withstand high pressure and perform efficiently in industrial applications.

- Q: How are steel coils used in the production of power transmission towers?

- Steel coils are used in the production of power transmission towers as they provide the necessary strength and durability to support the towers and withstand the transmission lines' weight and environmental conditions. The steel coils are shaped and welded into various sections and components, such as the legs, base plates, and cross arms, which are then assembled to create the tower structure. The coils' high tensile strength ensures the towers can withstand the mechanical stresses and loads imposed by the transmission lines, making them a crucial component in the construction of power transmission towers.

- Q: i got the belly button ring from icing and its surgical steel are they the same things?

- yes they are same kind of steel

- Q: Can steel coils be transported by air?

- Yes, steel coils can be transported by air.

- Q: Is 440 steel relatively strong or weak?

- Grade 440C is one of the highest strength stainless steels. It is also very wear resistant. Good for use as ball bearings and other high wear applications. 400C has the highest carbon content of the 440 steels. 440A and 440B are identical but have lower carbon contents and have lower strengths and higher corrosion.

- Q: What are the common uses of pre-painted steel coils?

- Pre-painted steel coils are commonly used in various industries such as construction, automotive, and appliances. They are utilized for manufacturing roofing and wall panels, garage doors, ductwork, and other building components. In the automotive sector, pre-painted steel coils are employed to produce body panels, trims, and other exterior parts. Additionally, they find applications in the manufacturing of household appliances like refrigerators, washing machines, and ovens.

- Q: What are the different types of coatings applied to steel coils?

- There are multiple types of coatings that can be applied to steel coils, including galvanized coatings, which involve applying a layer of zinc to prevent corrosion; organic coatings, such as paints or lacquers, which provide protection and enhance aesthetics; and metallic coatings, like aluminum or tin, which offer corrosion resistance and improved appearance.

- Q: Why cold rolled stainless steel sheet is lower than cold rolled stainless steel coil?

- Kaiping is the flat coil set into common size. A negative tolerance is the actual thickness of the plate, not the thickness of the mark.

- Q: How are steel coils used in the manufacturing of furniture?

- Steel coils are used in the manufacturing of furniture to provide structural support and stability. They are commonly used in the construction of sofa frames and mattress bases to ensure durability and longevity. The coils are typically formed into springs, which are then incorporated into the furniture to enhance comfort and provide a responsive seating or sleeping surface.

- Q: How are steel coils used in the production of metal ductwork?

- The production of metal ductwork relies heavily on steel coils. Typically constructed from high-quality steel, these coils serve as the primary raw material for manufacturing ductwork. To begin the process, the steel coil is unwound and then cut into specific lengths based on the required dimensions of the ductwork. These lengths are then shaped using specialized machinery, such as roll formers or bending machines, to achieve the desired form. The steel coils are essential in providing the necessary strength and durability to the ductwork, ensuring its ability to withstand the pressure and environmental conditions it may encounter during operation. Additionally, the composition of the coil allows for easy fabrication and customization, enabling manufacturers to produce ductwork in various shapes and sizes to meet specific project requirements. Moreover, steel possesses inherent properties that make it an ideal material for ductwork. Its resistance to corrosion and fire makes it highly desirable. Steel coils can also be coated with protective layers, such as galvanized or stainless steel finishes, to further enhance their longevity and performance. This added protection ensures that the ductwork remains intact and functional, even in harsh environments or when exposed to corrosive substances. In conclusion, steel coils are indispensable in the production of metal ductwork as they provide the necessary raw material for fabrication. Their strength, durability, and customization capabilities make them a crucial component in the manufacturing process, resulting in reliable and long-lasting ductwork systems.

Send your message to us

color Coated gAlvanized Cold rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords