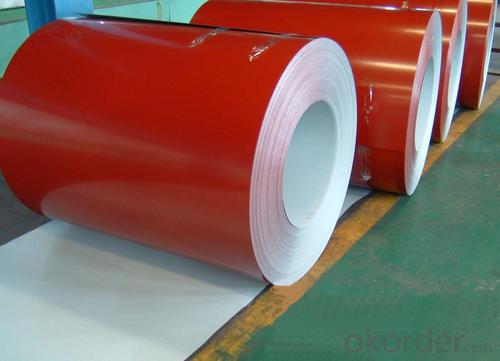

Color Coated Galvanized Cold Rolled Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color coated hot rolled steel coil takes hot-dip galvanized steel coil asits basic material. Factory adopts the newest technologies and the mostadvanced equipments to degrease, rinse, chemical transform the cold-rolledsteel coils or galvanized steel coils. Then we make primary and refined lavation

for the steel strips. We use worldwide advanced solidify furnace to solidify the coasting surface.This kind of color painted coils has excellent capability of decoration, molding,

corrosion resistance ability. It keeps the products with color coatings inflamboyant color for a long time.Nowadays, it has become the most perfect building materials in construction, transportation,

manufacture, light industry, office furniture, household electric appliances,

food package, and other areas all over the world.

Features:

1) Thickness: 0.2 - 1.5mm

2) Width:<1250mm

3) Lacquer: according to customer's needs

4) The color-coated steel coil is produced by hot-galvanized steel and color-coated with the paint produced according to the American standards

5) The combining force between the galvanized steel and the paint is very strong

6) The surface is polish

7) Coat fabric 2/2 (two coats for top / two coats for bottom)2/1 (two coats for top / single coat for bottom)1/1 (single coat for top / single coat for bottom)

8) Colors: white, black, sky blue, bright red, yellow

9) Can be used in building material field, galvanized wire steel tape and all other fields.

- Q: Hi I was thinking about buying this knife, but i wasn't sure if it was good because it's stainless steel.

- This isn't really a question for this section, but I'm still happy to help out since I'm a big cutlery nerd as well. One thing to look out for when buying a knife is a lack of specifics on what steel is being used. High Carbon Stainless Steel doesn't tell you what the steel is, just what it MIGHT be. Chances are it's something along the lines of 420HC or 440A, both of which are softer steels. They aren't the worst steels around, but they are very quick to dull. You'd be better off looking at the Balisongs of Benchmade. They'll cost more, but you'll know that you're getting something made with quality materials and that won't break on you. And if it does break for some odd reason, Benchmade's warranty and customer service are both fantastic. Although if a more questionable knife is okay with you as long as the price isn't too high, then at least 420HC and 440A aren't too brittle and will take a decent edge even though they'll dull quickly. As for whether stainless steel is good for a knife or not, that depends on the type of stainless steel and what you're going to use the knife for. Many stainless steels are more brittle than a carbon steel, so high carbon stainless steels are a bit more likely to rust but a little tougher as well. In a butterfly knife, a steel like that is a good way to go, although the steels used by Benchmade, as I mentioned, are of a much better quality.

- Q: How are steel coils used in the production of steel fasteners?

- Steel coils are used in the production of steel fasteners by being processed into flat strips or wires, which are then cut, shaped, and threaded to create various types of fasteners such as screws, bolts, and nuts. The coils provide a continuous supply of steel material that is easily manipulable and can be efficiently transformed into the desired shape and size for fastener production.

- Q: What is the average shelf life of a painted steel coil?

- The average shelf life of a painted steel coil can vary depending on several factors such as the type of paint used, the storage conditions, and the level of exposure to environmental elements. However, on average, a painted steel coil can have a shelf life ranging from 5 to 20 years.

- Q: What are the main challenges in handling and processing steel coils?

- The main challenges in handling and processing steel coils include their large size and weight, which require specialized equipment and techniques for safe transportation and storage. Coils also tend to have sharp edges, posing a risk of injury. Additionally, maintaining the integrity and quality of the steel during processing can be challenging due to the potential for surface damage, rust, or deformation. Proper handling, storage, and processing techniques are crucial for minimizing these challenges and ensuring the efficient production of steel products.

- Q: How are steel coils labeled for identification?

- Steel coils are typically labeled for identification using a combination of unique alphanumeric codes, barcodes, or labels that include important information such as the coil's dimensions, weight, grade, production date, and supplier details.

- Q: How do steel coil manufacturers ensure timely delivery?

- Timely delivery is ensured by steel coil manufacturers through a variety of strategies and measures. Their first priority is to maintain a well-coordinated system for production and supply chain management. This involves efficiently scheduling production processes, monitoring inventory levels, and closely coordinating with raw material suppliers. In addition, advanced forecasting techniques are often employed by steel coil manufacturers to predict product demand. By analyzing historical data, market trends, and customer behavior, they can anticipate future orders and plan production accordingly. This proactive approach minimizes the risk of delays and allows for better allocation of resources. Furthermore, close collaboration with transportation and logistics companies is essential to ensure smooth and timely delivery. Strategic partnerships are established and favorable agreements negotiated to facilitate efficient transportation of steel coils to customers. This includes optimizing routes, utilizing reliable carriers, and closely tracking shipments to promptly address any unforeseen issues. Moreover, buffer stocks may be maintained by manufacturers to mitigate the impact of unexpected disruptions, such as equipment failures or supplier delays. By having a safety stock of finished products, they can quickly respond to urgent orders and uphold their delivery commitments. Lastly, effective communication plays a crucial role in ensuring timely delivery. Steel coil manufacturers maintain open lines of communication with their customers, keeping them informed about production progress and potential delays. This transparency allows for proactive problem-solving and helps manage customer expectations. In conclusion, steel coil manufacturers employ efficient production and supply chain management systems, advanced forecasting techniques, collaboration with transportation and logistics companies, buffer stocks, and effective communication to ensure timely delivery. These strategies collectively enable them to meet delivery deadlines and provide reliable service to their customers.

- Q: i recently got an industrial piercing and instead of getting pierced with a metal bar i have a PTFE bar .. i eventually want to put in a metal bar but what kind do i get? whats the difference between a surgical steel and titanium bar?thanks

- 316L steel is the most basic metal used in body jewelry. It is the basic requirement of metal to be used in initial piercings and for healing. There are better grades but usually they cost more as well. For most people this grade of steel works just fine. Titanium is usually preferred over steel because it contains no nickel and it weighs almost 50% less than steel. Titanium can come in plain polish which looks just like steel AND it can come in a variety of colors (but NOT red or black). Titanium is super for people with sensitive skin to steel. It does cost a little more but is well worth it.

- Q: How are steel coils used in the manufacturing of tubes?

- Steel coils are used in the manufacturing of tubes by being processed through a series of steps such as slitting, forming, and welding. These coils are slit into narrower strips, which are then formed into a cylindrical shape and welded together. This process allows for the efficient production of seamless or welded tubes, which can be used in various industries such as construction, automotive, and oil and gas.

- Q: What are the different methods of coil recoiling for narrow strip widths?

- There exists a variety of techniques for coil recoiling targeted at narrow strip widths. One technique, known as slitting and recoiling, entails slicing the wide coil into narrower strips and then rewinding them onto a smaller coil. This is typically accomplished using a slitting machine, which can make precise cuts to achieve the desired strip widths. Another approach, referred to as edge trimming and recoiling, involves trimming the edges of the wide coil to generate narrower strips. The remaining material is then rewound onto a smaller coil. This method is commonly employed when the coil edges are damaged or uneven and need to be removed before recoiling. Furthermore, there is a method called tension recoiling. In this process, the wide coil is threaded through a series of tensioning devices that aid in achieving the desired strip widths. The tensioning devices can apply controlled pressure to the coil edges, enabling precise recoiling of narrow strips. Additionally, some companies opt to employ laser cutting technology for coil recoiling. This technique entails using a laser beam to slice the wide coil into narrow strips, which are then rewound onto a smaller coil. Laser cutting offers exceptional precision and accuracy, making it an ideal choice for narrow strip widths. In summary, the various methods of coil recoiling for narrow strip widths consist of slitting and recoiling, edge trimming and recoiling, tension recoiling, and laser cutting. Each approach possesses its own merits and is selected based on the specific requirements and capabilities of the manufacturing process.

- Q: How are steel coils inspected for camber?

- Steel coils are inspected for camber by using a straight edge or a camber gauge, which is placed on top of the coil to measure any deviation from straightness. The operator checks the distance between the straight edge and the coil at various points along its length to determine the amount of camber present.

Send your message to us

Color Coated Galvanized Cold Rolled Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords