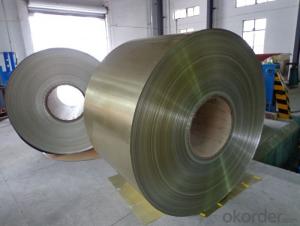

Palatiuzed Aluminum Coils for Color Coated Aluminum Roll in Cladding Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Color Coated Aluminium Roll For Aluminium Cladding Panel

Specifications

Grade | 1050,1060,1070, 1100, 1200, 2024,3003, 3004,3005, 3105, 5005,5052 5182,5754,8011 etc |

Thickness | 0.1~1.5mm |

Width | 100~2500mm |

Surface Treatment | PVDF and PE coated |

Temper | O-H112 |

Hardness | More than 2H |

Yield(≥MPa) | 160 |

Ultimate Strength(≥MPa) | 175 |

Elongation(≥%) | 6 |

Packing Material | Moisture-proof agent, steel tape bundle, wooden pallet, brown paper |

Method | Vertical(eye to sky) or horizontal(eye to wall) |

Standard Specification | 1000mm×C, 1200mm×C, etc |

Shipping | Container Loading or Bulk Pack |

Characteristics

1) Excellent weather-proof durability

2) Anti-ultraviolet

3) High erosion resistance

4) Stable color and gloss

5) Good mechanical processing performance

6) Abrasion resistance

7) Anti-impact

8) High flexibility

Application

1) Construction material further processing

2) Solar cell frame, solar battery frame

3) Glass curtain wall frame

4) Interior decoration

5) Elevator decoration

6) Signs, nameplate, bags making.

7) Automobile parts material

8) Office and Household appliances: HVAC equipments

9) The consumer electronics: mobile phones, digital cameras, MP3 .etc.

Coating varieties

Polyester Coatings (PE)

PE (polyester) coatings exhibit an excellent combination of hardness, flexibility, flow, appearance, and superior resistance to dirt retention in indoor and outdoor applications. These coatings are highly resistant to abrasion, metal marking, staining, and marring, and require minimal maintenance. Glazetech uses polyester paints which provide excellent colour and gloss retention properties.

Polyvinylidene Fluoride Coatings (PVDF)

PVDF (polyvinylidene fluoride) is a chemical resistant thick film barrier coating commonly used in architectural applications where both excellent appearance and substrate protection must be maintained over a long period of time. This coating is unaffected by most chemicals and solvents and has excellent wear and abrasion resistance. PVDF also has a high dielectric strength, excellent resistance to weathering and the ability to self extinguish.

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What’s the coating of top side?

--A: PVDF and PE coating

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112, T3, T4, T6

- Q: Can aluminum coils be used in the production of aluminum composite ceilings?

- Yes, aluminum coils can be used in the production of aluminum composite ceilings. Aluminum coils are often used as the base material for manufacturing aluminum composite panels, which are then used to create ceilings. These coils are typically made of high-quality aluminum alloy and have undergone various processes to ensure their strength, durability, and aesthetic appearance. The aluminum coils are coated with a protective layer, such as PVDF or polyester, to enhance their resistance to weathering, UV rays, and corrosion. This coating also allows for a wide range of color options, providing flexibility in design choices for aluminum composite ceilings. Overall, aluminum coils are an essential component in the production of aluminum composite ceilings, offering a lightweight, fire-resistant, and long-lasting solution for various architectural and interior design applications.

- Q: What is the thickness range of aluminum coils?

- The thickness range of aluminum coils typically varies between 0.15mm to 4mm.

- Q: How do aluminum coils contribute to sustainable transportation systems?

- Aluminum coils play a significant role in promoting sustainable transportation systems in several ways. Firstly, aluminum is a lightweight material that helps reduce the overall weight of vehicles, resulting in improved fuel efficiency and reduced carbon emissions. The use of aluminum coils in vehicle manufacturing can contribute to enhancing the fuel economy of automobiles, which is crucial for sustainable transportation. Moreover, aluminum is a highly recyclable material, with nearly 75% of all aluminum ever produced still in use today. This recyclability factor makes aluminum coils a sustainable choice as they can be easily recycled and reused without compromising their quality. By incorporating recycled aluminum coils into vehicle production, manufacturers can reduce energy consumption and greenhouse gas emissions associated with primary aluminum production. Additionally, aluminum is highly resistant to corrosion, making it a durable material for various automotive applications. The longevity of aluminum coils ensures that vehicles require less maintenance and replacement parts, reducing waste and contributing to sustainable transportation systems. Furthermore, the use of aluminum coils in electric vehicles (EVs) is particularly advantageous. EVs require lightweight components to maximize battery efficiency and increase the driving range. Aluminum coils fulfill this requirement by providing the necessary lightweight construction without compromising safety or performance. By enabling the production of lightweight EVs, aluminum coils contribute to the wider adoption of electric vehicles, which have a significantly lower carbon footprint compared to traditional internal combustion engine vehicles. In summary, aluminum coils contribute to sustainable transportation systems by reducing vehicle weight, improving fuel efficiency, and reducing carbon emissions. Their recyclability, durability, and compatibility with electric vehicles further enhance their sustainability credentials. Incorporating aluminum coils in vehicle manufacturing is a step towards achieving a greener and more sustainable transportation future.

- Q: How do aluminum coils compare to other types of metal coils?

- Aluminum coils have several advantages and disadvantages when compared to other types of metal coils. One of the main advantages of aluminum coils is their lightweight nature. Aluminum is significantly lighter than other metals such as copper or steel, making it easier to handle and transport. This lightweight property also makes aluminum coils more cost-effective in terms of shipping and installation. Furthermore, aluminum coils are highly resistant to corrosion, which is a significant advantage in many applications, especially in humid or corrosive environments. This resistance to corrosion makes aluminum coils suitable for outdoor use, such as in air conditioning systems or refrigeration units. Additionally, aluminum coils have excellent thermal conductivity, allowing for efficient heat transfer. This property makes them highly efficient in heat exchange applications, such as in HVAC systems or automotive radiators. However, aluminum coils also have some drawbacks. Compared to copper coils, aluminum coils have lower electrical conductivity, which can result in higher energy consumption and reduced efficiency in certain applications. Additionally, aluminum is a softer metal than copper or steel, which means that aluminum coils may be more susceptible to damage or bending. In summary, aluminum coils offer advantages such as lightweight, corrosion resistance, and thermal conductivity. However, they may have lower electrical conductivity and be more prone to damage compared to other types of metal coils. The choice between aluminum coils and other types of metal coils ultimately depends on the specific application and its requirements.

- Q: Aluminum alloy coil quotation = = how much is the price?

- 8.3 kilometers, towards the Heze / Dongping /G35 direction, a little right turn, into the Canton Expressway11. along the economy wide highway 280 meters, Ji'nan Yin Jia Lin hub interchange after about 160 meters, go straight into the economy wide highway12., along the Canton Expressway 50.7 kilometers, in Pingyin exports, slightly turn right into the Pingyin interchange13., along the Pingyin interchange 510 meters, 650 meters after crossing Pingyin, straight14. drive 440 meters, turn left ahead into G220 (old)15. along the G220 (old) 1.1 km road, go straight into the Ping Street16. along the Ping Street 3.1 km road, turn left into the road rose17. drive along Rose Road for 510 meters, to the finish line (on the right side of the road)Terminus: Pingyin forever Aluminium Industry Co., Ltd.

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Yes, aluminum coils can be used in the production of aircraft fuel tanks. Aluminum is a lightweight and durable material that is commonly used in the aerospace industry due to its high strength-to-weight ratio. Its corrosion-resistant properties also make it an ideal choice for fuel tanks, as it can withstand the harsh conditions and chemicals found in aviation fuel. The use of aluminum coils allows for efficient manufacturing processes, as they can be easily formed and welded into the desired tank shape. Additionally, aluminum has excellent thermal conductivity, which helps dissipate heat generated during flight and prevents the fuel from overheating. Overall, aluminum coils are a suitable and widely-used material in the production of aircraft fuel tanks.

- Q: What are the maximum and minimum coil weights available?

- The maximum and minimum coil weights available can vary depending on the specific type of coil being referred to. In the context of electrical coils, such as those used in transformers or motors, the maximum and minimum coil weights are determined by factors such as the size and material of the wire used, the number of turns in the coil, and the intended application. These coils can range from very small and lightweight to much larger and heavier, with weight limits typically specified by manufacturers. For example, a small coil might have a maximum weight of a few grams, while a larger coil could weigh several kilograms. It is important to consult the specifications provided by the manufacturer or supplier of the specific coil to determine the maximum and minimum coil weights available for a particular application.

- Q: Yep a slogan...the element Aluminum

- Aluminum, unlucky # 13. or...Aluminum, fun to say-hard to chew. Aluminum says, stop staring at my cans. I 3 recycling.

- Q: Can the little can opening cap things on an aluminum can be recycled? My friend told me if you fill a two liter bottle with them you can get loads of cash. Is this true?

- Yes. Aluminium can be recycled. (watch the TV ad, UK) No. You would need tons of the stuff ( a tonne of copper is only around ?1000) They are usually colleced for charity. And they save up all the 2 litre bottles full! Feel the weight, aluminium is very light.

- Q: This question asks about potential health hazards linked to the use of aluminum coils in culinary settings.

- <p>There are some concerns about using aluminum cookware due to the potential for aluminum to leach into food, especially at high temperatures or in acidic environments. While the human body needs small amounts of aluminum, excessive intake can be harmful. It has been linked to neurological disorders, although the evidence is not conclusive. Most health organizations, including the FDA, consider aluminum cookware safe for general use. However, for those who are concerned, alternatives like stainless steel, cast iron, or non-stick coatings are available. It's always best to follow manufacturer's guidelines and avoid using aluminum cookware for acidic or highly acidic foods to minimize any potential risk.</p>

Send your message to us

Palatiuzed Aluminum Coils for Color Coated Aluminum Roll in Cladding Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords