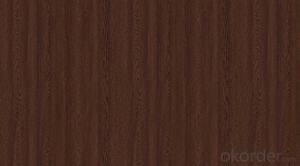

color bond surface coating steel plate--XY017

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Color bond surface coating steel plate :

2.More than ten years experiences, the products are sold to the domestic city and some international cities we strivc to develop production of color coating steel plate the plating (aluminum )zinc steel. Coil cheickness between 0.6mm and 1.5mm and the width from 600mm to 1250mm and a variety of high durability of color coating steel plate.

3.The company has multiple layer patterns for customers to choose The company provides products deep processing services ,meet the various needs of customers on board specifications All of out products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world

4. If you ate interested in any of our products or would like to discuss a custom order please feel free to contact us we are looking forward to forming successful business relationships with new clients around the world in the near future.

5.We can design the color and thickness according to customers' requirements. The delivery time is only 30 day after you confirm the order.

- Q: Can steel sheets be used for transportation equipment?

- Yes, steel sheets can be used for transportation equipment. Steel is a widely used material in the transportation industry due to its strength, durability, and cost-effectiveness. Steel sheets are commonly used in the construction of various transportation vehicles such as cars, trucks, buses, trains, ships, and airplanes. They can be used for the body panels, chassis, frames, and other structural components of these vehicles. Steel sheets offer excellent mechanical properties, including high tensile strength and impact resistance, making them suitable for withstanding the stresses and demands of transportation applications. Additionally, steel is also known for its ability to be easily formed and welded, allowing manufacturers to create complex shapes and structures required for transportation equipment.

- Q: Are steel sheets suitable for automotive body panels?

- Yes, steel sheets are suitable for automotive body panels. They provide excellent strength, durability, and crash-resistance, making them a popular choice in the automotive industry. Additionally, steel sheets are cost-effective and easily customizable, making them an ideal material for automotive body panels.

- Q: What are the different types of finishes available for steel sheets?

- There are several different types of finishes available for steel sheets, each offering unique properties and aesthetic appeal. Some of the most common finishes include: 1. Mill Finish: This is the standard finish that is achieved after the steel sheet has been manufactured. It has a rough, dull appearance, typically with visible surface imperfections. 2. Hot Rolled Finish: This finish is achieved by subjecting the steel sheet to high temperatures during the manufacturing process, resulting in a scaly, rough surface. It is commonly used for structural applications where appearance is not a primary concern. 3. Cold Rolled Finish: This finish is achieved by cold rolling the steel sheet, which smooths out the surface and creates a clean, matte appearance. It is commonly used for applications that require a smooth and uniform surface, such as automotive panels or appliances. 4. Galvanized Finish: This finish is achieved by applying a layer of zinc to the steel sheet through a process called galvanization. It provides excellent corrosion resistance and is commonly used in outdoor applications, such as roofing or fencing. 5. Electroplated Finish: This finish is achieved by electroplating a thin layer of metal, such as chromium or nickel, onto the steel sheet. It provides enhanced corrosion resistance, improved aesthetics, and can be available in various colors. 6. Powder-Coated Finish: This finish involves applying a dry powder coating onto the steel sheet and then curing it with heat. It provides a durable and attractive finish, with various color options available. Powder coating also offers excellent corrosion resistance. 7. Brushed Finish: This finish is achieved by brushing the surface of the steel sheet with an abrasive material, creating a distinctive brushed pattern. It is commonly used for decorative applications, such as architectural elements or kitchen appliances. 8. Polished Finish: This finish involves polishing the steel sheet to create a smooth and reflective surface. It is commonly used for decorative applications that require a high level of aesthetics, such as ornamental pieces or jewelry. Overall, the choice of finish for steel sheets depends on the specific requirements of the application, including factors such as durability, corrosion resistance, aesthetics, and cost.

- Q: How are steel sheets inspected for defects?

- Steel sheets are inspected for defects using various techniques and methods to ensure their quality and reliability. One common method is visual inspection, where trained inspectors carefully examine the surface of the steel sheet for any visible defects such as cracks, scratches, dents, or surface irregularities. This is typically done under proper lighting conditions to enhance visibility. Another technique is magnetic particle inspection, which is used to detect surface or near-surface defects in ferromagnetic materials like steel. In this method, a magnetic field is applied to the steel sheet, and iron particles are then applied to the surface. If there are any defects, these particles will be attracted and form visible indications, allowing inspectors to identify the location and size of the defect. Ultrasonic inspection is another commonly used method that involves the use of high-frequency sound waves to detect internal defects in steel sheets. Ultrasonic waves are passed through the material, and any changes in the wave patterns caused by defects are detected by sensors. This non-destructive testing method can identify defects such as voids, cracks, or inclusions that may not be visible to the naked eye. Other techniques used for defect detection in steel sheets include eddy current testing, where electrical currents are induced in the material to detect surface defects, and X-ray inspection, which uses high-energy X-rays to reveal any internal flaws. Overall, a combination of visual inspection and non-destructive testing methods is employed to thoroughly inspect steel sheets for defects, ensuring that only high-quality sheets are used in various applications like construction, automotive, or manufacturing industries.

- Q: What is the density of steel sheets?

- The density of steel sheets typically ranges from 7.8 to 8.1 grams per cubic centimeter.

- Q: What is the average moisture resistance of steel sheets?

- The average moisture resistance of steel sheets can vary depending on the specific type of steel and its protective coatings. Generally, steel sheets have good moisture resistance due to their inherent corrosion resistance properties. However, the resistance can be further enhanced by applying various surface treatments such as galvanization, which adds a layer of zinc to protect against moisture and corrosion. In terms of specific values, it is difficult to provide an exact average moisture resistance without considering the specific steel grade, thickness, and coating. Typically, steel sheets with galvanized coatings can provide excellent moisture resistance, with some studies reporting corrosion rates as low as 0.1-0.5 micrometers per year in highly corrosive environments. It is crucial to note that the performance of steel sheets in resisting moisture can also be influenced by other factors such as the presence of scratches, cuts, or exposure to chemicals. Regular maintenance, inspection, and proper handling of steel sheets can help ensure their optimal moisture resistance over time.

- Q: Can steel sheets be painted after installation?

- Yes, steel sheets can be painted after installation. The paint can adhere to the surface of the steel sheets, providing protection against corrosion and enhancing their appearance.

- Q: What are the different edge finishes available for steel sheets?

- Some of the different edge finishes available for steel sheets include mill edge, sheared edge, slit edge, deburred edge, and rounded edge.

- Q: Can steel sheets be used for cladding or facade systems?

- Yes, steel sheets can be used for cladding or facade systems. Steel is a durable and versatile material that offers excellent structural support and weather resistance. It can be shaped into various profiles and finishes, making it suitable for creating aesthetically pleasing and functional building facades.

- Q: Can steel sheets be used in aerospace applications?

- Yes, steel sheets can be used in aerospace applications. While steel is not as commonly used as other materials like aluminum or titanium in aerospace, it can still be employed in certain specific applications such as structural components or engine parts where its high strength, durability, and resistance to extreme temperatures are beneficial.

Send your message to us

color bond surface coating steel plate--XY017

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords