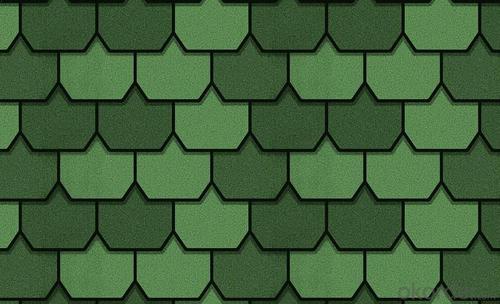

color bond surface coating steel plate--XY009

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Color bond surface coating steel plate :

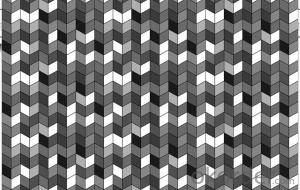

2.More than ten years experiences, the products are sold to the domestic city and some international cities we strivc to develop production of color coating steel plate the plating (aluminum )zinc steel. Coil cheickness between 0.6mm and 1.5mm and the width from 600mm to 1250mm and a variety of high durability of color coating steel plate.

3.The company has multiple layer patterns for customers to choose The company provides products deep processing services ,meet the various needs of customers on board specifications All of out products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

4.If you ate interested in any of our products or would like to discuss a custom order please feel free to contact us we are looking forward to forming successful business relationships with new clients around the world in the near future.

5.We can design the color and thickness according to customers' requirements. The delivery time is only 30 day after you confirm the order.

- Q: Can steel sheets be used for solar panel manufacturing?

- Yes, steel sheets can be used for solar panel manufacturing. Steel is a versatile and widely used material in various industries, including renewable energy. It has several advantages that make it suitable for solar panel manufacturing. Firstly, steel is a durable and robust material, which provides structural integrity to solar panels. It can withstand harsh weather conditions and protect the delicate photovoltaic (PV) cells inside the panels. This durability ensures a longer lifespan for the solar panels, reducing maintenance and replacement costs. Secondly, steel sheets can be easily fabricated into different shapes and sizes, allowing for customization based on the specific requirements of solar panel designs. This flexibility in manufacturing enables the creation of efficient and aesthetically pleasing solar panels. Furthermore, steel is a cost-effective material compared to other alternatives like aluminum or glass. It is widely available and has relatively low production costs, making it an economical choice for solar panel manufacturing. However, it is important to note that steel sheets used in solar panel manufacturing are typically coated with protective layers to enhance their corrosion resistance and prevent any adverse effects on the PV cells. These coatings protect the steel from environmental factors such as moisture or chemicals, ensuring the longevity and performance of the solar panels. In conclusion, steel sheets can indeed be used for solar panel manufacturing due to their durability, versatility, cost-effectiveness, and ease of fabrication. With appropriate coatings, steel can provide a reliable and efficient solution for the production of solar panels, contributing to the growth of the renewable energy sector.

- Q: What are the different sheet metal finishing techniques for steel sheets?

- Some of the different sheet metal finishing techniques for steel sheets include deburring, grinding, polishing, sanding, and painting.

- Q: What is the difference between a laminated and non-laminated steel sheet?

- Laminated steel sheets, which are produced by bonding multiple layers of steel with adhesive or resin, are known for their increased strength and durability. This lamination process enhances their resistance to bending, impact, and corrosion. Additionally, it reduces noise and vibration in applications like automotive bodies or construction materials. In contrast, non-laminated steel sheets consist of a single layer of steel without undergoing the lamination process. While these sheets are still robust and long-lasting, they may not possess the same level of resistance to bending, impact, and corrosion as laminated steel sheets. They are commonly used in roofing, siding, and general fabrication. The key distinction between laminated and non-laminated steel sheets lies in their composition and properties. Laminated steel sheets offer superior strength, durability, and resistance to various forces, making them ideal for demanding applications where structural integrity is crucial. On the other hand, non-laminated steel sheets are more cost-effective and suitable for applications where high strength and durability are not the primary requirements.

- Q: What is steel concrete?

- Steel reinforced concrete (Steel Reinforeed Concrete, referred to as SRC) refers to the concrete structure of main steel, and is equipped with a longitudinal and transverse stirrup reinforcement structure, is a main form of steel and concrete composite structure.

- Q: How are steel sheets protected during storage in outdoor environments?

- Steel sheets are protected during storage in outdoor environments through the application of various protective measures. These measures may include the use of weather-resistant coatings, such as galvanization or paint, to prevent corrosion and rusting. Additionally, steel sheets can be stored on pallets or racks to minimize contact with the ground and reduce the risk of moisture accumulation. Covering the sheets with tarpaulins or using weatherproof storage containers further shields them from direct exposure to rain, snow, and sunlight. Regular inspections and maintenance are crucial to ensure the effectiveness of these protective measures and to address any potential issues promptly.

- Q: How can steel plates with a thickness of 1MM be welded?

- 1mm steel plate is best made by spot welding or flash welding, for example, electrical welding will cause plate deformation

- Q: Can steel sheets be used for transportation applications?

- Transportation applications can indeed make use of steel sheets. Steel has gained immense popularity in the automotive and aerospace sectors owing to its exceptional strength, durability, and resistance to corrosion. Chassis, body panels, doors, and structural parts in various transportation components are often constructed using steel sheets. These sheets offer remarkable structural integrity and can endure substantial loads, making them ideal for vehicles and aircraft. Moreover, steel sheets can be effortlessly shaped, welded, and machined, enabling customization and efficient manufacturing procedures.

- Q: What is the process of embossing on steel sheets?

- Embossing on steel sheets involves the creation of raised or recessed designs on the surface. This technique is commonly used for texture enhancement, aesthetic improvement, or to enhance the mechanical properties of the steel. To begin the embossing process, the steel sheets are prepared. This involves cleaning the surface to remove any dirt, oils, or coatings that could interfere with the embossing. The sheets are then inspected for imperfections or defects that may impact the embossing quality. Once prepared, the steel sheets are placed in an embossing machine consisting of two or more rollers. These rollers have engraved patterns that will be transferred onto the steel sheets. They are typically made of hardened steel or other durable materials. As the steel sheets pass through the embossing machine, pressure is applied to the rollers, causing them to press against the steel surface. This creates a plastic deformation in the sheet, resulting in the desired raised or recessed pattern. The depth and intensity of the embossing can be adjusted by controlling the pressure applied by the rollers. In certain cases, heat may be used during the embossing process to soften the steel sheets, making them more malleable. This allows for deeper and more intricate embossing patterns. The temperature and duration of the heating process depend on the type of steel and desired outcome. After embossing, the steel sheets may undergo additional treatments such as cleaning, coating, or polishing to further enhance their appearance and protect them from corrosion. These finishing steps ensure that the embossed steel sheets meet quality standards and are ready for use. Overall, embossing on steel sheets is a versatile and effective method for adding texture and visual interest. It requires careful preparation, precise machinery, and skilled operators to achieve consistent and high-quality results.

- Q: What is the weight of each steel sheet?

- The weight of each steel sheet depends on its dimensions and thickness, as steel comes in various sizes and densities.

- Q: What is the difference between a perforated and expanded steel sheet?

- A perforated steel sheet is a flat metal sheet with evenly spaced holes, typically created through a mechanical punching process. On the other hand, an expanded steel sheet is formed by cutting and stretching a solid metal sheet, resulting in a grid-like pattern with diamond-shaped openings. While both provide ventilation, drainage, and visibility, perforated sheets offer more precise hole patterns and sizes, making them suitable for applications that require specific hole arrangements. Expanded sheets, on the other hand, provide a more rigid structure, making them ideal for walkways, catwalks, and platforms.

Send your message to us

color bond surface coating steel plate--XY009

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords