Color Aluminum Sheets with Mapp Gas - Orange Pattern Embossed and PE Painted Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Orange Pattern Embossed and PE Painted Aluminum Coils

We professionally produce stucco embossed and coated aluminum coils, which are widely used in refrigerators, ice-boxes, cold storage, freezer, etc.

Stucco embossed and coated aluminum sheets look more beautiful and better at strength and rigidity than normal aluminum coils.

We normally use 3105, H44 as base coils. Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

2. Main Features of Orange Pattern Embossed and PE Painted Aluminum Coils

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

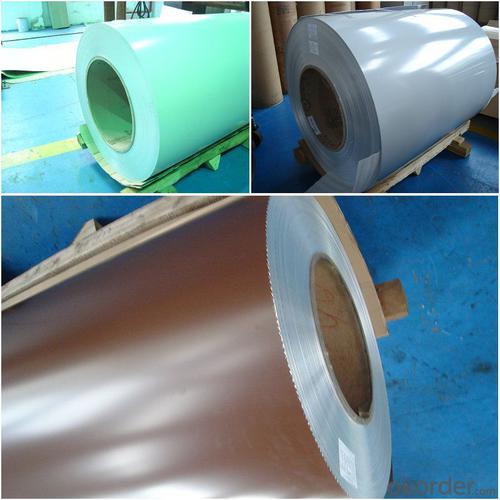

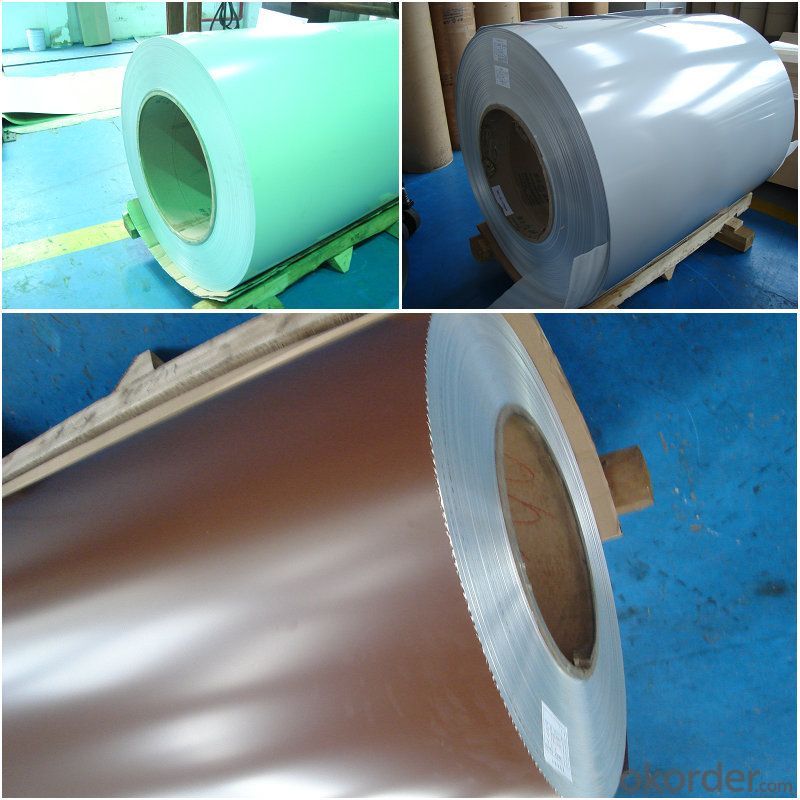

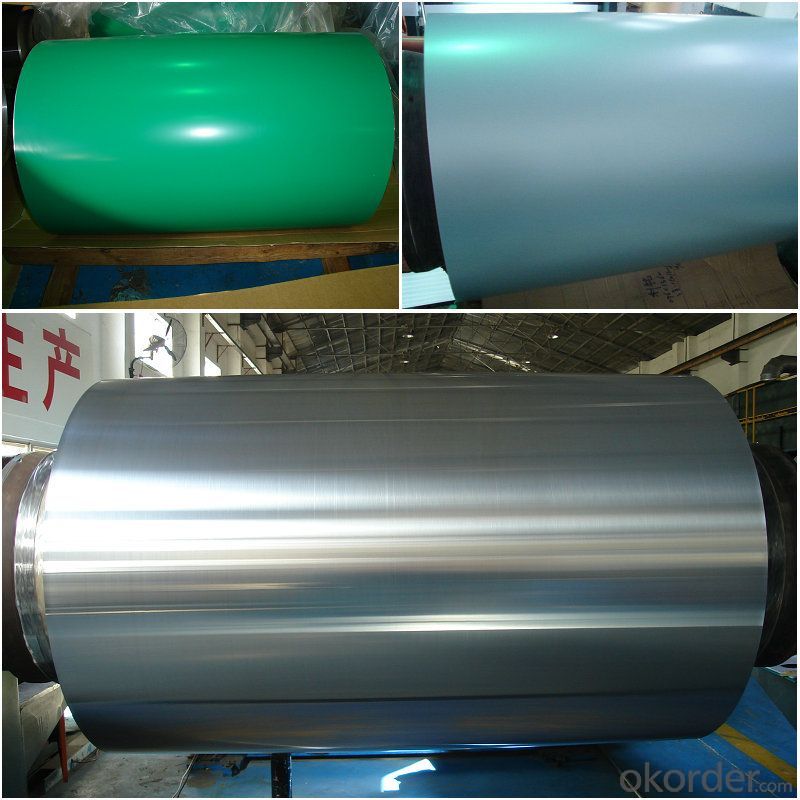

3. Orange Pattern Embossed and PE Painted Aluminum Coils Images

4. Specification of Orange Pattern Embossed and PE Painted Aluminum Coils

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Are aluminum sheets suitable for outdoor uses like fences or signs?

- <p>Yes, aluminum sheets are commonly used for outdoor applications such as fences and signage. Aluminum is lightweight, durable, and resistant to corrosion, making it ideal for outdoor conditions. It can withstand various weather elements without rusting. Additionally, aluminum can be easily formed into different shapes and sizes, and it's available in a wide range of colors and finishes, which makes it versatile for both functional and aesthetic purposes in outdoor settings.</p>

- Q: Can aluminum sheets be easily shaped or bent into desired forms?

- Yes, aluminum sheets can be easily shaped or bent into desired forms. Aluminum is a highly malleable metal, which means it can be easily manipulated without breaking or cracking. Its low density and high strength-to-weight ratio make it an ideal choice for various applications where shaping or bending is required. Aluminum sheets can be shaped or bent using a variety of methods, including press-braking, roll-forming, or using specialized tools such as a sheet metal brake. The ease of shaping or bending aluminum sheets also makes it a popular choice for industries such as automotive, aerospace, construction, and manufacturing, where customized forms and designs are often needed.

- Q: How does the surface finish affect the optical properties of aluminum sheet?

- The surface finish of aluminum sheet can greatly impact its optical properties. A smooth surface finish can enhance the reflectivity and brightness of aluminum, making it more reflective and shiny. On the other hand, a rough surface finish can scatter and diffuse light, reducing the reflectivity and making the aluminum appear dull. Therefore, the surface finish plays a crucial role in determining the optical qualities of aluminum sheet.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- The Principle behinf Microwave oven heating is that it heats up only water molecules, that is, the frequency of microwaves can only heat up water molecules ( make them oscillate and hence heat up). So if there is any trace of water or moisture on any object that you keep in the oven, it will heat up and that heat will be conducted throughout the object. Hence the foil with moisture is effectively heated whereas dry foil have no water moecule and hence will not be heated up. Hope it helps:) Can explain better if you tell me which level you are studying:)

- Q: Explain the pros and cons of utilizing aluminum sheets in the construction of car body panels.

- <p>Aluminum sheets offer several advantages for car body panels, such as reduced weight, which can improve fuel efficiency and handling. They also have high resistance to corrosion, enhancing the vehicle's durability. Additionally, aluminum is easier to recycle, contributing to environmental sustainability. However, there are downsides, including higher cost compared to steel, which can affect the vehicle's price. Aluminum is also less malleable, making it more challenging to repair after accidents, potentially leading to higher repair costs. Furthermore, aluminum's lower strength compared to steel can necessitate thicker panels to achieve the same structural integrity, which may offset some of the weight savings.</p>

- Q: What are the different packaging options available for aluminum sheets during transportation?

- To ensure the safety and intactness of aluminum sheets during transportation, various packaging options are available. Some commonly employed choices are: 1. Wooden Crates: Strong and durable wooden crates offer formidable protection against impacts and rough handling. These crates can be tailored to the size and weight of the sheets. 2. Cardboard Boxes: For smaller quantities or sheets of smaller sizes, cardboard boxes are a popular option. The sheets are stacked and securely packed inside the boxes, which are then sealed to prevent movement or damage during transit. 3. Pallets: Wooden or plastic platforms called pallets provide convenient handling and transportation. The sheets are stacked and fastened to the pallets using straps, ensuring stability and protection during shipping. 4. Stretch Wrap: Another alternative is to tightly wrap the aluminum sheets together using a plastic film. This stretch wrap secures the sheets in place, shielding them from scratches and minor damages. 5. Protective Film: It is common practice to apply a protective film on the surface of the aluminum sheets before packaging. This film acts as a barrier, safeguarding against moisture, dust, and scratches during transportation. 6. Edge Protectors: To prevent damage to the edges of the aluminum sheets, edge protectors made of plastic or cardboard can be used. These protectors absorb impacts, ensuring the sheets remain intact. 7. Customized Packaging: Depending on the specific requirements and transportation method, customized packaging solutions can be devised. Foam inserts, dividers, or additional cushioning materials can be utilized to provide maximum protection during transit. Choosing the appropriate packaging option is crucial and should be based on factors such as size, weight, fragility of the aluminum sheets, mode of transportation, and distance to be traveled. Proper packaging is paramount in preventing damage and ensuring the sheets arrive at their destination in optimal condition.

- Q: Can aluminum sheets be used for wall cladding?

- Yes, aluminum sheets can be used for wall cladding. Aluminum is a popular choice for cladding due to its lightweight nature, durability, and corrosion resistance. It can be easily shaped and installed, making it a versatile option for various architectural applications, including wall cladding.

- Q: What are the properties of anodized aluminum sheets?

- Anodized aluminum sheets have a protective oxide layer that provides increased corrosion resistance, durability, and a decorative finish. They are lightweight, non-toxic, and offer excellent heat and electrical conductivity. Additionally, anodized aluminum sheets are easy to clean, resistant to fading and scratching, and can be dyed in various colors for aesthetic purposes.

- Q: Can aluminum sheet be used for electrical grounding applications?

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a highly conductive material, making it suitable for use in grounding systems. It is often used in various electrical applications due to its low resistance and excellent electrical conductivity. Aluminum sheet can effectively carry electrical current and safely dissipate it into the ground, ensuring the protection of electrical systems and preventing electrical hazards. Additionally, aluminum's lightweight and corrosion-resistant properties make it a preferred choice for grounding applications in various industries, including construction, automotive, and aerospace.

Send your message to us

Color Aluminum Sheets with Mapp Gas - Orange Pattern Embossed and PE Painted Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords