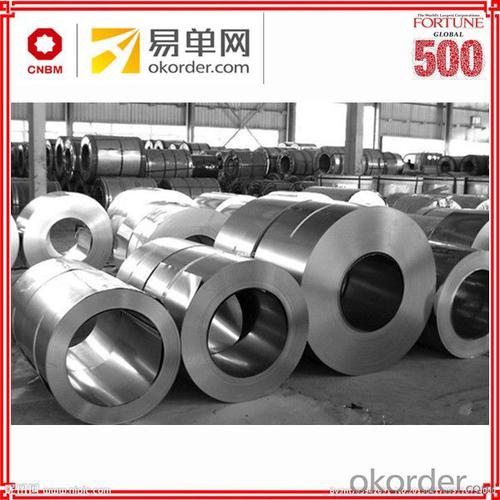

Cold steel coil building material prices china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 54223 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolled sheet products have been available for many, many years, and have been successfully used for a multitude of

applications. Today's cold rolled sheet products are much improved over those used in the past. They offer better control of

thickness, shape, width, surface finish, and other special quality features that compliment the emerging need for highly

engineered end use applications.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

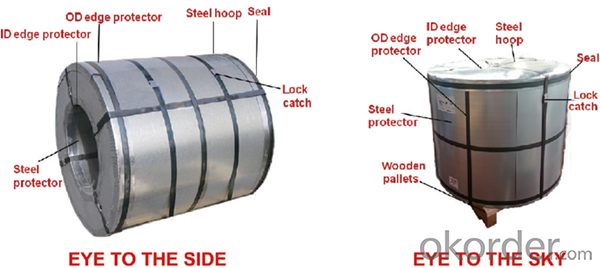

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: How are steel coils processed for slitting or edge trimming?

- Steel coils are processed for slitting or edge trimming by feeding the coil into a slitting or trimming machine. The machine uses sharp rotating blades to cut the coil into smaller strips or remove the excess material from the edges. This process helps to create narrower coils or achieve precise edge dimensions for various applications.

- Q: why do you need to heat steel when hardening, molecules etc etc

- Heat treatment deforms the crystal micro structure of the Steel. With heat (and cold) treatment the organisation or Diffusion of the micro particles can be manipulated. There is a higher concentration of particles after heat treatment, thus making the micro structure of the steel more dense, and the physical performance of the steel better. Stronger. Hope this helps ! Please like.

- Q: Does te game end with broken steel? What is broken steel? I bouht it cuz my buddy said I should.

- Broken Steel is an addon that lets you continue the story after the business with the final battle for the Purifier and extends to level cap to... 30? 40? Can't quite remember. In Broken Steel you side with the BoS to wipe up what is left of the Enclave in the Capital Wastelands, in the end infiltrating and (possibly) destroying a huge armored crawler-base (or you can blow up the Citadel, the BoS HQ, your call). Anyway the game won't end after your final decision and you can continue wreaking havoc over the wasteland, exploring, whatever.

- Q: Hi All,I was wanting to know,on the quality bikes such as Trek,Giant etc is the aluminum frames as strong as the steel frame bikes? I have heard conflicting reports on this,so thought I would ask here for more input.Thanks!

- Steel is stronger than aluminum. But, you have to consider the strength to weight ratio and stiffness. Modern aluminum frames use hydro-forming to optimize the tube shapes. They also use modern welding and bonding techniques. In short, a good aluminum frame can be better than a steel frame and have less weight. Consider a Cannondale CAAD alloy frame or a hybrid composite/alloy frame such as a Cannondale Six. Cannondale is know for pioneering alloy frames.

- Q: What is the average width tolerance for steel coils?

- The average width tolerance for steel coils can vary depending on the specific requirements and standards set by the industry. However, a common range for width tolerance in steel coils is typically around ±0.005 to ±0.030 inches.

- Q: I noticed that Jimmy Page finger picked on a steel acoustic guitar on quite a few tracks like Stairway to heaven and other ones and I was wondering how did he do it? I know it is more difficult to finger pick on a steel acoustic because of the rougher steel strings and higher tensions so I was wondering do they make specific strings that allow for fingerstyle playing? Also Randy Rhoads finger picked a steel acoustic on Dee along with a Classical guitar.

- First okorder /... In truth their are many, many players who finger pick acoustic guitars, once you get the hang of the various picking patterns it's not extremely difficult to do. There aren't really any specific strings that are required to finger pick. It will mostly come down to the players preference and the type of music they are doing. It is actually more difficult to finger pick an electric guitar since you have less room between the strings and the pickup so you will find that a lot of times you will hit the pickup with the metal finger pick which can be a bit disturbing but practice helps. Pat SImmons of the Doobie Brothers uses finger picks on a Gibson ES335 all the time.

- Q: What are the different types of steel coil surface treatments for durability?

- There are several different types of steel coil surface treatments that can enhance the durability of the material. 1. Hot-dip galvanizing: This process involves immersing the steel coil in a bath of molten zinc, creating a protective zinc coating on the surface. Hot-dip galvanizing provides excellent corrosion resistance and can extend the lifespan of the steel coil. 2. Electro-galvanizing: In this method, a thin layer of zinc is electrodeposited onto the surface of the steel coil. Electro-galvanizing offers good corrosion resistance and is commonly used for indoor applications or where a thinner coating is desired. 3. Powder coating: Powder coating involves applying a dry powder paint to the surface of the steel coil and then curing it under heat. This creates a durable, uniform, and attractive finish that is resistant to chipping, scratching, and fading. 4. Organic coatings: Organic coatings, such as acrylics, polyesters, or fluoropolymers, are often applied to steel coils to provide protection against corrosion, UV rays, and other environmental factors. These coatings can enhance the durability and aesthetics of the steel coil. 5. Chromate conversion coating: This treatment involves applying a thin layer of chromate onto the surface of the steel coil. Chromate conversion coatings provide corrosion resistance and can improve the adhesion of subsequent paint or powder coating layers. Each of these surface treatments offers unique benefits in terms of corrosion resistance, durability, and appearance. The choice of treatment depends on the specific application requirements and the level of protection needed for the steel coil.

- Q: How do steel coils compare to stainless steel coils?

- Steel coils and stainless steel coils find extensive use in various industries due to their robustness and durability. Nevertheless, selecting the appropriate material necessitates considering some essential distinctions between the two. One of the primary disparities lies in the composition of the materials. Steel coils, primarily comprising iron and carbon, incorporate additional elements to enhance specific properties. Conversely, stainless steel coils contain iron, carbon, and a substantial amount of chromium, which imparts them with distinctive corrosion-resistant attributes. Owing to the presence of chromium, stainless steel coils outperform regular steel coils in their resistance to corrosion, tarnishing, and rust. This renders stainless steel coils highly suitable for applications within environments characterized by elevated humidity, moisture, or exposure to corrosive substances. On the contrary, steel coils are more susceptible to rust and may necessitate supplementary protective coatings or treatments to avert corrosion. Another notable differentiation concerns the visual appearance of the two materials. Stainless steel coils boast a lustrous and reflective surface, endowing them with an aesthetically pleasing allure. They commonly find application in contexts where appearance holds significance, such as kitchen appliances, architectural structures, or decorative purposes. Conversely, steel coils exhibit a matte or dull finish and are frequently employed in industrial applications where visual aesthetics are of secondary concern. In terms of strength, both steel and stainless steel coils exhibit excellent mechanical properties. However, stainless steel coils generally demonstrate greater tensile strength and enhanced resistance to high temperatures. Consequently, they prove well-suited for applications necessitating strength, such as the construction, automotive, or aerospace industries. Lastly, cost represents a factor warranting consideration while comparing steel coils to stainless steel coils. Steel coils generally offer a more cost-effective option due to the lower expense of raw materials and simpler manufacturing processes. Nevertheless, when factoring in the added value of corrosion resistance and longevity, stainless steel coils may emerge as a more economical choice in the long run, requiring less maintenance and replacement. To conclude, steel coils and stainless steel coils possess distinct properties and characteristics, rendering them suitable for specific applications. Stainless steel coils exhibit superior corrosion resistance, a glossy appearance, and heightened tensile strength, while steel coils prove more cost-effective. Ultimately, the selection between the two hinges on the precise requirements of the application, encompassing factors such as the environment, aesthetics, strength, and budget.

- Q: Hey Guys, I'm planning on purchasing a bmx bike and I have been recommended by many people the Kink Launch 2012. I'm thinking of getting it but the frame is made from High Tensile steel and I know the chromoly is stronger and more expensive, but I plan to use my bmx just to chill, ride with friends and some times go through dirt trails at my park, I would like to know, how strong Hi Tensile steel is and can it handle jumps not massive jumps but like jumps where you get like 3 feet high (1m) just for fun, I might go to the skate park but I'm not gonna do tail whips and massive jumps, I just want it as a mobile piece of transportation. I don't want to buy a mtb because I already had 3 of them and they are not practical to take with you on holidays.So, do you think the Kink Launch 2012 is good enough or should I cough up an extra $80 and get the gap ($500 AU)? As I said I ain't gonna do huge jumps.

- High tensile steel could mean almost anything. SAE 4130 Chrome-Moly steel is the de-facto standard for steel bikes frames. High tensile steel could actually mean the same thing since chrome-moly is classified as high strength steel. The strength of the frame depends as much on the quality of the welds and on the size/thickness of the tubing as much as anything else. I'd say what kind of steel you use makes only a minor difference. One reason you want to buy bikes from reputable name-brand companies is they tend to have strict quality controls, this is particularly important when it comes to welds. Welds are always the weakest part of any bike frame, don't let anyone tell you different. 99% of the time if something in the frame breaks, it'll be at the welds. hope this helps.

- Q: What are the different methods of coil slitting for precision cuts?

- There are several methods of coil slitting for precision cuts, including rotary slitting, loop slitting, and double knife slitting. Rotary slitting involves using a circular blade to cut through the coil, while loop slitting utilizes a looping mechanism to create tension and then cuts the coil with a straight blade. Double knife slitting, on the other hand, employs two blades that move in opposite directions to cut the coil. These methods enable precise and efficient cutting of coils into narrower strips for various industrial applications.

Send your message to us

Cold steel coil building material prices china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 54223 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords