Steel sheet in coil cold rolled from alibaba website

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 57623 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

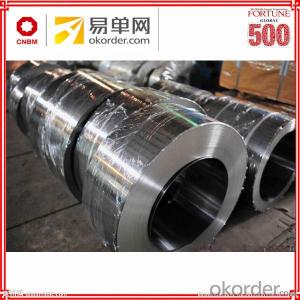

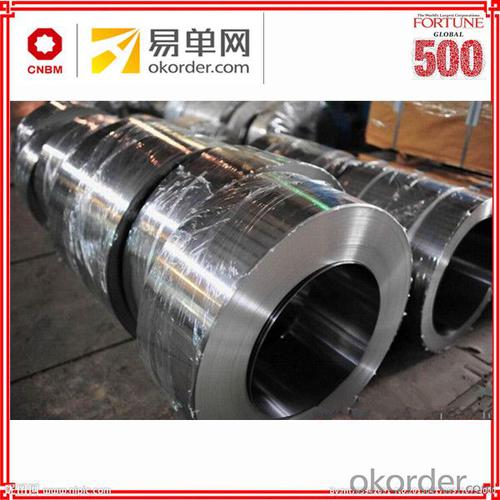

Cold Rolled Steel coil is a mill product made with a high degree of gauge accuracy and uniformity of physical characteristics.

The smooth deoxidized matte finish gives an excellent base for paint, lacquer and enamel. Box annealing and absence of scale

permit stamping and moderate drawing operations. Sheets bend flat on themselves without cracking. Oiling protects Surface

against rust. The application of surface oil to cold rolled steel coil/sheet is intended to provide protection from corrosion ("rusting")

during shipment and warehousing.

Because cold rolled steel sheet is prone to rusting, standard practice is to apply a rust-preventative oil at the exit end of the temper mill (the last processing step). Rust-preventative oils are different than forming lubricants in that they contain special corrosion-inhibiting additions. In addition to the oil, Curtis Steel maintains clean, dry environments in climate controlled warehouses at all its facilities

to ensure our coils and sheets arrive to you in prime condition.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

Packing:

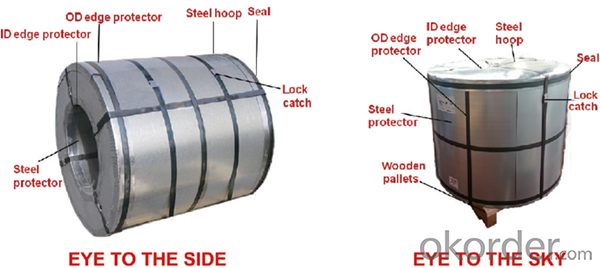

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: Are steel sheets suitable for food storage applications?

- Yes, steel sheets are highly suitable for food storage applications. They are durable, resistant to corrosion, and provide a hygienic and safe storage environment for food products. Steel sheets can maintain the freshness and quality of food while protecting it from external contaminants.

- Q: How do steel sheets perform in cryogenic environments?

- Steel sheets perform well in cryogenic environments due to their low thermal expansion coefficient, high strength, and good ductility. At extremely low temperatures, steel retains its structural integrity, resists cracking or brittleness, and maintains its mechanical properties. This makes steel sheets suitable for various applications in cryogenic industries, such as liquefied natural gas (LNG) storage tanks, aerospace components, and scientific research facilities.

- Q: Are the steel sheets suitable for outdoor signage?

- Yes, steel sheets are suitable for outdoor signage. Steel is known for its strength, durability, and resistance to weather conditions. It can withstand harsh outdoor environments, including extreme temperatures, rain, wind, and sunlight, without warping or deteriorating. The thickness of steel sheets can be adjusted based on the size and design of the signage to ensure stability and longevity. Additionally, steel sheets can be easily customized and painted to match the desired aesthetic, making them a popular choice for outdoor signage projects.

- Q: Can steel sheets be used in energy applications?

- Yes, steel sheets can be used in energy applications. Steel sheets are commonly used in the construction of power plants, wind turbines, and solar panels due to their high strength, durability, and resistance to extreme temperatures. They are also used in the manufacturing of energy-efficient appliances and energy storage systems.

- Q: What are the different surface finishes for steel sheets?

- There are several different surface finishes for steel sheets, including mill finish, brushed finish, mirror finish, embossed finish, and coated finish.

- Q: Are steel sheets resistant to warping under heat?

- Yes, steel sheets are generally resistant to warping under heat due to their high melting point and thermal stability.

- Q: How do you prevent rusting on steel sheets?

- To prevent rusting on steel sheets, a few effective methods can be employed. Firstly, applying a protective coating such as paint, varnish, or a specialized rust-resistant primer can create a barrier between the steel and moisture, preventing rust formation. Additionally, keeping steel sheets dry and avoiding prolonged exposure to moisture, especially in humid environments, can significantly reduce the risk of rusting. Regularly inspecting and promptly addressing any scratches or damages on the steel surface by applying touch-up paint or protective sealants is also crucial in preventing rust from spreading. Finally, storing steel sheets in a dry and well-ventilated area can further minimize the chances of rust formation.

- Q: Can steel sheets be used in furniture applications?

- Yes, steel sheets can be used in furniture applications. Steel sheets are commonly used in the construction of various furniture pieces such as tables, chairs, shelving units, and storage cabinets. They provide strength, durability, and a modern aesthetic to furniture designs. Additionally, steel sheets can be easily formed and shaped into different configurations, making them versatile for various furniture styles and functions.

- Q: How thick is steel filing cabinet usually made of steel plates?

- A lot of people will hold 0.6 of the said 0.8 material, this is because the cold rolled plate after forming electrostatic spraying powder and environmental protection, so it is actually only 0.6mm 0.8mm bare steel, on this point, if you are purchasing large quantities of words, can use vernier caliper to card

- Q: What is the difference between a smooth and patterned steel sheet?

- A smooth steel sheet has a uniform surface without any visible texture or pattern, while a patterned steel sheet has a deliberate design or texture imprinted on its surface for aesthetic or functional purposes.

Send your message to us

Steel sheet in coil cold rolled from alibaba website

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 57623 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords