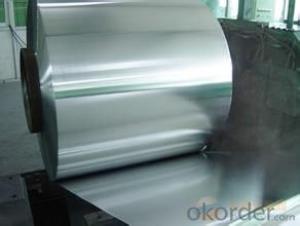

COLD ROLLED STEEL COILS/SHEETS SPCC/DC01

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Name | Cold Rolled Sheet Coil |

Material | SPCC/SPCD/SPCE/DC01/ST12/ ST14/SPCD/DC03/DC04 ect. |

Grade Standard | JIS G3302, EN10142, ASTM653, ASTM95 |

Thickness | 0.15-3.5mm |

Width | 600mm-1500mm |

Coil ID | 508-610mm |

Coil OD | max 1500mm |

Weight | 3-10 Tons |

Tolerance | Thickness tolerance:+/-0.02mm; Width tolerance:+/-5mm |

Surface | No-skin passed or Skin passed, Tensile leveled |

Surface Treatment | Chromate/Unchromate passivation, fingerprint resistant treatment, oiled/unoiled |

Annual Output | 350,000MT |

Application | Construction, hardware, home applicances, interior decoration |

General Application of Cold Rolled Steel Coil:

Classification | Designation | Characteristics | Main applications |

Commercial quality | SPCC SPCCT | Commercial quality suitable for bending fabrication and simple forming; this is the type in greatest demand. | Refrigerators, cabinets, power distribution baords and drums. |

Drawing quality | SPCD | Drawing quality second only to that of SPCEN. Excellent uniformity. | Automobile floor and roof panels. |

Deep-drawing quality | SPCE SPCF | Deep-drawing quality.With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn. | Automobile fenders and quarter panels |

Extra deep-drawing quality | SPCG | Extra-low-carbon steel sheets with highest workability | Automobile internal panels and deep-drawn parts |

- Q: What is the fatigue strength of steel sheets?

- The fatigue strength of steel sheets refers to the maximum stress level that the sheets can sustain for a certain number of cycles without failing due to fatigue.

- Q: What are the advantages of using steel sheets in automotive manufacturing?

- Automotive manufacturing can benefit from the utilization of steel sheets for several reasons. Firstly, the high strength and durability of steel sheets make them well-suited for enduring the demanding conditions and stresses encountered by vehicles on the road. This remarkable strength ensures the production of safer and more dependable vehicles, as steel sheets provide a robust protective structure capable of absorbing impact energy in the event of a collision. Secondly, steel sheets possess exceptional formability, allowing them to be easily shaped and molded into various intricate designs required for automotive components. This adaptability permits the creation of precise and elaborate parts, guaranteeing a flawless fit and optimal performance. Moreover, steel sheets exhibit commendable resistance to corrosion, a crucial characteristic for automotive applications. Vehicles encounter a variety of environmental factors such as moisture, salt, and chemicals, which can lead to rust and corrosion. However, by utilizing steel sheets with protective coatings, manufacturers can ensure that their vehicles have an extended lifespan and preserve their aesthetic appeal. Additionally, steel sheets present themselves as a readily available and cost-effective alternative to other materials used in automotive manufacturing. Steel is extensively utilized in numerous industries, which has resulted in the establishment of a well-developed supply chain for steel sheets. This accessibility not only guarantees a consistent supply for automotive manufacturers but also assists in maintaining manageable production costs. Lastly, steel sheets possess excellent thermal conductivity, which is essential for effective heat dissipation in automotive applications. Vehicles generate a substantial amount of heat, particularly in the engine and exhaust systems. Steel sheets aid in efficiently transferring and dissipating this heat, preventing overheating and ensuring optimal performance. In conclusion, the advantages of utilizing steel sheets in automotive manufacturing encompass high strength and durability, exceptional formability, commendable resistance to corrosion, cost-effectiveness, and efficient heat dissipation. These factors make steel sheets the preferred choice for the production of safe, reliable, and long-lasting vehicles.

- Q: Are steel sheets suitable for railway track construction?

- Steel sheets are indeed suitable for constructing railway tracks. The reason lies in the exceptional durability and strength of steel as a material, which makes it perfect for withstanding the heavy loads and constant traffic of trains. Railway tracks often utilize steel sheets as the foundation, providing a stable base for the rails and ensuring reliability and stability. Furthermore, steel possesses remarkable resistance to wear, corrosion, and deformation, which are vital factors in maintaining the long-term performance of railway tracks. Its high strength-to-weight ratio also allows for lighter track structures and reduces the need for frequent maintenance. All in all, steel sheets are a favored option in railway track construction due to their robustness, longevity, and cost-effectiveness.

- Q: Can steel sheets be used for fire-rated doors?

- Yes, steel sheets can be used for fire-rated doors. Steel is a commonly used material for fire-rated doors due to its inherent fire-resistant properties and durability.

- Q: Can steel sheets be used for radiation shielding?

- Yes, steel sheets can be used for radiation shielding. Steel is a dense material that effectively blocks and attenuates various forms of radiation, making it suitable for shielding applications in industries such as nuclear power, healthcare, and aerospace.

- Q: Can steel sheets be used for manufacturing machinery parts?

- Indeed, machinery parts can be manufactured using steel sheets. Steel, as a material, possesses remarkable versatility and durability, thereby offering exceptional strength and rigidity necessary for the production of diverse machinery components. The malleability, ease of cutting, and weldability of steel sheets enable the creation of intricate shapes and structures essential for machinery parts. Furthermore, steel exhibits commendable resistance against corrosion, guaranteeing the longevity of the machinery components. Moreover, steel sheets ensure dimensional stability and can endure substantial loads and elevated temperatures, rendering them a perfect selection for the manufacturing of machinery parts.

- Q: Can the steel sheets be used for kitchen countertops?

- Kitchen countertops can indeed be made from steel sheets. Steel proves itself as a durable and enduring material, capable of withstanding high temperatures, rendering it fitting for kitchen purposes. Moreover, it is resistant to stains, scratches, and water damage, simplifying cleaning and maintenance. Furthermore, steel countertops can lend a sophisticated and contemporary appearance to any kitchen. Nevertheless, it is essential to be mindful that steel is susceptible to scratches and dents, necessitating caution when handling sharp utensils or heavy objects on the countertop.

- Q: What are the different packaging options available for steel sheets?

- There are various packaging options available for steel sheets, depending on their size, shape, and intended use. Some common packaging options include: 1. Wooden crates: Steel sheets are often packed in wooden crates, which provide sturdy protection and prevent damage during transportation. The sheets are secured inside the crate using straps or bands to ensure they remain in place. 2. Steel frames: Another option is to package steel sheets in steel frames. This method provides extra protection and stability, especially for larger or heavier steel sheets. The frame is designed to securely hold the sheets in place and prevent any shifting during transit. 3. Coil packaging: Steel sheets that are in the form of coils are often packaged differently. They can be wrapped in plastic or paper to protect them from moisture, dust, and other environmental factors. The coils are then typically placed on pallets to facilitate easy handling and transportation. 4. Bundles: Steel sheets can also be bundled together using steel straps or bands. This packaging method is commonly used for smaller sheets or when multiple sheets need to be packaged together. The bundles can be further secured with shrink wrap or plastic covers to ensure they stay intact during shipping. 5. Custom packaging: Depending on specific requirements or customer preferences, steel sheets can be packaged in custom-designed packaging. This can include using foam padding or inserts to protect delicate or sensitive surfaces, or using specialized containers for specific applications such as food-grade steel sheets. Overall, the packaging options for steel sheets are diverse and can be tailored to meet the needs of different industries and customers. The choice of packaging will depend on factors such as sheet size, weight, level of protection required, and transportation method.

- Q: Are steel sheets suitable for elevator shafts?

- Yes, steel sheets are suitable for elevator shafts. Steel is a widely used material in the construction industry due to its strength, durability, and fire resistance properties. Elevator shafts require a material that can withstand heavy loads, provide structural integrity, and meet safety standards. Steel sheets fulfill all these requirements, making them a suitable choice for elevator shafts. Steel sheets can be fabricated to the desired shape and size, allowing for flexibility in design. Additionally, steel can be easily maintained and repaired, ensuring the longevity of the elevator shaft.

- Q: Is color steel plate the same as color steel tile?

- Color steel plate color steel plate refers to color coated steel plate, color coated steel plate is a kind of organic coated steel plate.Color steel plate coating is cold-rolled steel sheet, galvanized steel sheet, after surface chemical treatment, coating (roll coating) or composite organic film (PVC film, etc.), and then baked, cured and made of products.

Send your message to us

COLD ROLLED STEEL COILS/SHEETS SPCC/DC01

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords