Cold rolled steel coil from china supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The raw material of cold rolled steel coil/sheet is high quality hot rolled product. Cold rolled steel coil/sheet as defined in the EN 10130/98 standard, with guaranteed maximum mechanical characteristics and guaranteed minimum ductility and formability.

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions and intended for indoor use.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

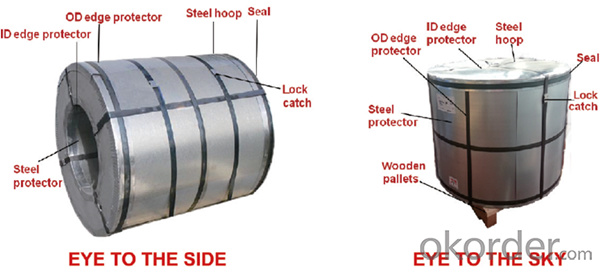

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What are the different methods of cutting steel coils?

- There are several methods of cutting steel coils, including shearing, slitting, laser cutting, and saw cutting.

- Q: All of my friends say that if a car made of mostly carbon fiber would crash into a full steel car, or vice versa, the steel car would be DESTROYED and the carbon fiber would drive away, if not, easily repairable.

- At a reasonably high speed, both cars would be undrivable. That's by design, not due to the strength/weakness of the materials. The energy in an impact needs to go somewhere. Cars are designed so the body and the frame will bend and break, reducing the impact on the occupants. If the car is too rigid the chances of the occupants being injured increases. Carbon fiber composites do have a better strength to weight ratio than steel but they're also a lot less dense, so the same volume of material will have a similar strength. The primary benefit to carbon fiber is that for a part of the same strength the carbon fiber part will weigh less than the steel part.

- Q: I just purchased this Benchmade knife with m390 steel blade and it cost me a fortune but I wanted to know if this new steel is a tool steel. what classifies a tool steel. M390 = 1.9 carbon, 20. chromium, .30 manganese, 1. molybdenum, .60silicon, .60 tugsten, 4. vanadium at 60-62 HRC

- Which has better songs - Number Of the Beast Which has better riffs - British Steel Which has better solos - Number of The Beast Which has better vocals - Number of the Beast Which has a cooler cover - Number of the Beast Which do You prefer - This is a real thinker, almost like Sophies Choice Metal edition. But I have owned Number and the Beast longer than I have owned British Steel. So I go with Iron Maiden Both albums get a perfect 10 because they deserve it, both have great musicianship and both have great vocals

- Q: What are the different types of steel surface finishes for coils?

- There are several types of steel surface finishes for coils, including hot rolled, cold rolled, galvanized, and coated finishes. Each finish offers unique properties and characteristics, such as improved strength, corrosion resistance, or aesthetic appeal. The choice of finish depends on the specific application and desired outcome for the steel coils.

- Q: I wanted to get a cheapo ring and I found one I like, but it's stainless steel. Is that bad? Will it get dull and tarnished fast?

- a lot of people that do a lot of manual labor with their hands prefer stainless steel because it can withstand potential damage on the job.

- Q: What are the common coil loading and unloading techniques?

- Some common coil loading and unloading techniques include using overhead cranes or forklifts to lift and move the coils, using coil cars or transfer tables to transport coils within a facility, utilizing coil hooks or C-hooks to securely hold and transport coils, and employing coil tilters or turnstiles to rotate or position coils for loading or unloading.

- Q: How much should someone sell a 6 ft stainless steel counter? How about one with a sink?

- Ask for the best offer on OKorder and find out.

- Q: what do you think about producebility of low density steel? for example: can density of 1020 steel (or ony others) be decreased without any loss of other properties.

- If a material has a lower density than steel, then it isn't steel.

- Q: I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- This Site Might Help You. RE: Why can aluminum and steel casings not be used for reloading? I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with a zinc-nickel alloy. Zinc-nickel alloy coating provides excellent corrosion resistance and is commonly used in various industries including automotive, construction, and manufacturing.

Send your message to us

Cold rolled steel coil from china supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords