Cold rolled coil steel coil hight quality building materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 52734 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolled steel coil/sheet is one of the main raw material of furniture automotive parts, industry steel parts, building construction,

raw material of color painted coil. Meanwhile we can provide full hard raw material they are properly used in the high strength

construction.

Because cold rolled steel sheet is prone to rusting, standard practice is to apply a rust-preventative oil at the exit end of the temper mill (the last processing step). Rust-preventative oils are different than forming lubricants in that they contain special corrosion-inhibiting additions. In addition to the oil, Curtis Steel maintains clean, dry environments in climate controlled warehouses at

all its facilities to ensure our coils and sheets arrive to you in prime condition.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

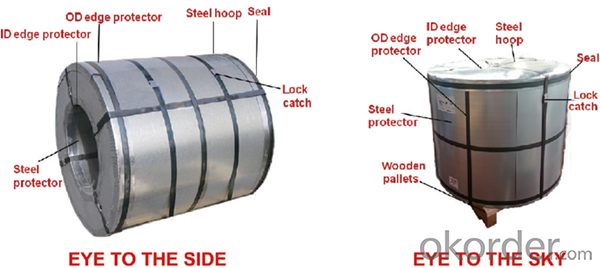

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What are the different types of steel coil cutting processes?

- Various industries utilize several different steel coil cutting processes. These processes include: 1. Shearing: The most widely used and simplest method of steel coil cutting involves utilizing a shear blade to cut the coil material into desired lengths. This can be done either manually or with the assistance of automated machinery. 2. Slitting: A process designed to cut wide coils into narrower strips, slitting involves passing the coil material through a set of circular knives that cut the steel into smaller coils or strips of the desired width. 3. Laser cutting: Renowned for its precision and efficiency, laser cutting involves using a high-powered laser to melt or vaporize the material along a predetermined path. This method is commonly employed for intricate designs or when high accuracy is required. 4. Plasma cutting: Another method of cutting steel coil involves using a plasma torch that generates a high-velocity jet of ionized gas to melt the material. Plasma cutting is known for its speed and ability to cut through thick materials. 5. Waterjet cutting: This process utilizes a high-pressure stream of water mixed with abrasive particles to cut through steel coil. Waterjet cutting is frequently chosen when the material being cut is sensitive to heat or when precision is necessary. 6. Saw cutting: A traditional cutting method, saw cutting involves using a saw blade with teeth to cut through the material. It is particularly effective for thicker materials and can be performed manually or with the aid of automated machinery. These represent just a few of the many steel coil cutting processes commonly employed. The choice of cutting method relies on several factors such as the material's type and thickness, desired accuracy, speed, and cost-effectiveness.

- Q: What is the process of slitting steel coils into narrower strips?

- The process of slitting steel coils into narrower strips involves unwinding the steel coil and passing it through a set of rotating circular blades. These blades cut the coil into narrower strips of the desired width. The strips are then rewound onto separate coils or packaged for further processing. This slitting process allows for the production of multiple narrower strips from a single large coil, making it more versatile and efficient for various applications.

- Q: I've heard on some 1911 forums that the slides of Armscor guns are now extruded. What is extruded steel? How is it made? Are they strong (4140carbon steel was used in the process).

- Extrusion okorder /

- Q: What are the environmental benefits of using steel coils?

- There are several environmental benefits associated with using steel coils. Firstly, steel is a highly recyclable material. Steel coils can be easily recycled and repurposed into new steel products, reducing the need for mining and extraction of raw materials. Recycling steel also requires less energy compared to producing it from scratch, resulting in lower greenhouse gas emissions and a smaller carbon footprint. Additionally, steel is known for its durability and longevity. When used in construction or manufacturing applications, steel coils can last for decades without losing their structural integrity. This reduces the need for frequent replacements, which in turn reduces the consumption of resources and energy required for production. Furthermore, steel is highly resistant to corrosion and weathering, making it a suitable choice for outdoor applications. This resistance to decay means that steel coils can withstand harsh environmental conditions and maintain their functionality for extended periods. This reduces waste generation and the associated environmental impacts of replacing damaged or deteriorated materials. Lastly, steel is a versatile material that can be used in a wide range of industries and applications. Its versatility allows for efficient use of resources, as steel coils can be easily adapted and customized to meet specific project requirements. This versatility also enables the use of steel in sustainable building designs, such as energy-efficient structures or green buildings that incorporate renewable energy systems. In conclusion, the environmental benefits of using steel coils include their recyclability, durability, resistance to corrosion, and versatility. By choosing steel coils for various applications, we can contribute to resource conservation, reduced carbon emissions, and a more sustainable future.

- Q: This question is directed to anyone who has played or know someone who plays a lap or pedal steel guitar.I've been a guitarist for about 8 years now and have played a variety of styles from rock, fingerstyle/classical, singer/songwriter acoustic stuff, ect, and now I've really had an interest in learning how to play a lap steel or pedal steel guitar. I am completely new to the instrument(s), so I'm seeking all the information I can. I do know that a pedal steel is a lot more expensive, so I'm probably looking to start on a lap steel for now. Basically how should I get started? Should I find a cheap lap steel at a pawn shop or purchase something new? Are there any good method books out there? I'm a pretty experienced guitarist, so should I expect to get the hang of it quickly? Is there much of a market for a lap/pedal steel player? haha.Also, I am left handed. How much trouble would it be to re-string a steel guitar? Or would I be better off getting a left-handed model?

- Hello okorder / I'm not familiar with the brand...it's certainly not commonly played....but it has the features you need for a starter guitar.

- Q: What are the different coil packaging machine configurations used for steel coils?

- There are several different coil packaging machine configurations used for steel coils, including horizontal coil packaging machines, vertical coil packaging machines, and orbital coil packaging machines. Horizontal coil packaging machines are typically used for smaller steel coils and provide a horizontal wrapping process. Vertical coil packaging machines are designed for larger steel coils and perform a vertical wrapping process. Orbital coil packaging machines use a rotating ring to wrap steel coils in a circular motion, providing maximum stability and protection. Each configuration offers specific advantages and is chosen based on the size and shape of the steel coils being packaged.

- Q: What are the different types of steel coil finishing tools?

- There are several types of steel coil finishing tools, including slitters, shears, levelers, and recoilers. These tools are used to cut, flatten, and rewind steel coils to achieve the desired shape and surface finish.

- Q: What are the main factors that affect the surface quality of steel coils?

- The main factors that affect the surface quality of steel coils include the quality of the raw materials used, the manufacturing process, the cleanliness of the production environment, the equipment and tools used, and the skill and expertise of the operators.

- Q: How long does the coating on steel coils last?

- The longevity of the coating on steel coils can vary depending on a variety of factors including the type of coating, environmental conditions, and usage. However, with proper maintenance and protection, a well-applied coating can typically last anywhere from 10 to 30 years.

- Q: I want to get one of these knives but I am having trouble deciding which is the best overall knife??ThanksSOG Trident tigerSOG Vulcan TantoSOG Bi-Polar (Serrated)Cold Steel ScimitarCold Steel Recon 1

- Look up a knife maker called Bench Made, the knife i recommend is the CQC7 its a tanto tip half serrated blade all low glare black folding with pocket clip. it has one of the hardest steel blades. You need to learn about steel hardness the harder the blade the sharper it can get and the harder the longer it will hold a edge. but hard steel can get brittle it can snap now as softer steel will bend and dull quick. the bench-made CQC7 goes for around $100 or that ball park...enjoy read some about the knife and think about what you want it for....my CQC7 can cut a coat hanger by pulling the serrate across the hanger!!

Send your message to us

Cold rolled coil steel coil hight quality building materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 52734 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords