Chinese Best Cold Rolled Steel Coil--Smooth and Flat Surface

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

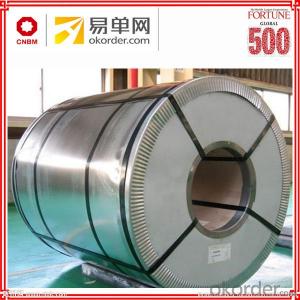

Chinese Best Cold Rolled Steel Coil--Smooth and Flat Surface

1.Structure of Chinese Best Cold Rolled Steel Coil--Smooth and Flat Surface:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed.

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

3. Cold Rolled Steel Images:

4.Cold Rolled Steel Specification:

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~2.0mm

Width: 1250mm MAX

Coil weight:3-12 MT

FAQ

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- The length of the roll is related to its width and thickness, but not to the extent of the zinc layer.

- Q: rust is not a issue. i was looking a D2 steel but heard story's of it chipping and breaking

- Ok, lets define what is Damascus steel. The modern Damascus is basically any steel that shows a pattern. Patterns are accomplished by 1. manipulating the crystal structure or 2. by combining 2 or more different alloys together. The blade you are looking at is referred to as a pattern welded blade. Damascus is only as strong as it's base components + heat treat and design. The strongest will be obtained by combining high carbon and low carbon steels. I do this by using steel cable. The patterns aren't real bold but are interesting none the less. To break it you must brake the hard steel and tear through the soft iron. The laminated stuff works the same way. For greater edge holding I use all high carbon, varying alloy content from simple carbon to chromium/nickle alloys. These are what you normally find in pattern welded blades. A fine pattern that has many lamination's crossing the edge will offer the best edge holding. Properly done one can get the DCE or damascus cutting effect where the soft layers wear away faster than the hard layers almost making the blade self sharpening. Is that blade good? Buy it if you like it, it won't compare to a well made hand forged blade but is much cheaper. sorry for the overload.

- Q: What are the different coil slitting methods used for steel coils?

- Steel coils can be slit into smaller, narrower coils using various methods. These methods serve the purpose of cutting the coils to suit specific applications. 1. The most commonly used method for coil slitting is blade slitting. Circular knives or blades are employed to cut the steel coil into narrower strips. These blades are placed at predetermined intervals and usually attached to a rotating shaft. As the coil passes through the blades, their circular motion slices through the coil, resulting in the desired narrower strips. 2. Another method, known as rotary shear slitting, involves the use of two sets of rotary shear knives to cut the steel coil. These upper and lower sets of knives rotate in opposite directions, creating a scissor-like cutting action. As the coil is fed through the shearing blades, the sharp edges of the knives slice through the coil, producing the desired narrower strips. 3. Sliding shear slitting is yet another method utilized for coil slitting. This method involves a stationary upper knife and a moving lower knife to cut the coil. The lower knife moves back and forth across the coil while the upper knife remains fixed. As the coil passes through the moving knife, it is cut into narrower strips. 4. Crush slitting is a less common method employed for coil slitting. In this method, the steel coil is fed through a set of rollers equipped with blades. Although the blades are not sharp, the pressure exerted by the rollers crushes and fractures the coil, resulting in the creation of the desired narrower strips. 5. Laser slitting is a modern and precise method used for coil slitting. It utilizes a laser beam to cut through the steel coil. The laser beam is directed onto the coil, and its high intensity melts and vaporizes the steel, creating a narrow slit. Laser slitting offers high accuracy and a clean cut, making it suitable for specialized applications. Each of these coil slitting methods possesses its own advantages and limitations. The choice of method depends on factors such as the type of steel, desired strip width, production volume, and required precision. Manufacturers select the most suitable method based on their specific requirements and the properties of the steel coils they are processing.

- Q: What kind of steel should be used for constructing a steel building?

- Please specify what kind of steel, is it structural steel (like wide flange, channel or Z-section) or reinforcing steel? For structural steel, all steel members that passed the requirement of ASTM-A360 are the best quality. While for reinforcing steel, it should passed the requirement of ASTM-D3963 for epoxy coated and ASTM-A615 (Grade 60) for deformed bars.

- Q: I want to save water $$, so I want to use frozen steel to cool my coke. possible or no?

- Wouldn't it be easier to stick your coke in the freezer?

- Q: What are the common coil transportation options?

- The common coil transportation options include trucking, rail transport, and sea freight.

- Q: How are steel coils used in the manufacturing of electrical equipment?

- Steel coils are commonly used in the manufacturing of electrical equipment as they serve as a key component in transformers and motors. These coils are typically made of high-quality steel and are tightly wound to create an electromagnetic field when an electric current passes through them. This allows for efficient power transmission, voltage regulation, and electromagnetic induction, which are essential functions in various electrical devices.

- Q: What is the difference between a steel strip and a coil? The steel strip is flat steel, and the steel coil is made of steel. Is that correct?

- A steel strip is also a coil, usually a narrow strip, also known as a steel strip. The volume is relatively wide. In addition, flat steel is usually hot-rolled out of long strip steel, fixed length 5 and 5.5,6 meters range, steel coil is Kaiping Chang 12501500, length 2.5 meters, 4 meters, 6 meters, ranging from steel plate

- Q: How are steel coils processed for galvanizing or coating?

- Steel coils are processed for galvanizing or coating through a series of steps. First, the coils are cleaned to remove any dirt, grease, or other contaminants. Then, they are dipped into a bath of molten zinc or coated with a protective layer using various methods such as electroplating or hot-dip coating. After the coating process, the coils may undergo further treatments like drying, cooling, and leveling to ensure uniformity and quality.

- Q: How are steel coils used in the manufacturing of crash structures?

- Steel coils are used in the manufacturing of crash structures as they provide strength, durability, and energy absorption capabilities. These coils are typically formed into various shapes and sizes to create components that reinforce the vehicle's body, such as side impact beams or front and rear crumple zones. The steel coils absorb and distribute the impact energy during a crash, helping to protect the occupants by minimizing the force transferred to the passenger compartment.

Send your message to us

Chinese Best Cold Rolled Steel Coil--Smooth and Flat Surface

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords