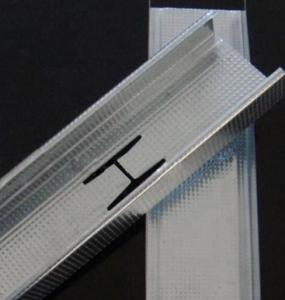

Cold formed Profile Steel Drywall for ceiling structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cold formed Profile Steel Drywall for ceiling structure

Instruction

Drywall Metal Profile

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe,

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Cold formed Profile Steel Drywall for ceiling structure

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

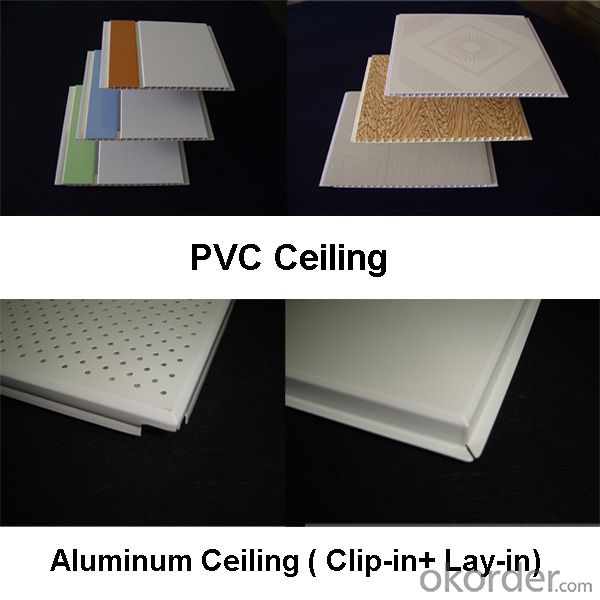

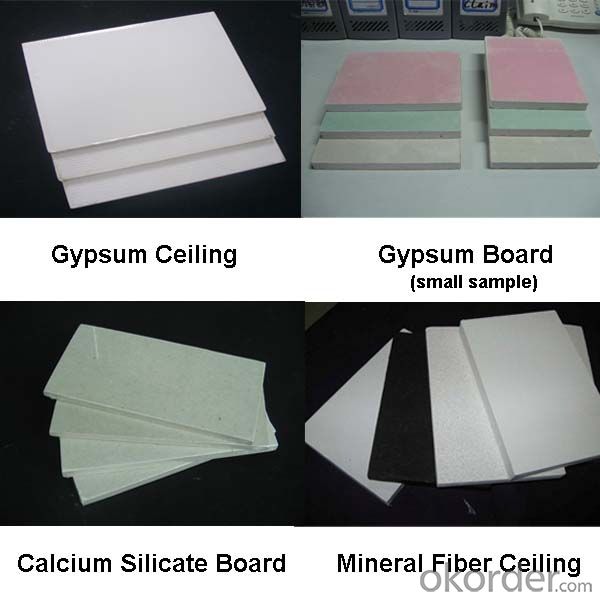

Other products we supply:

Cold formed Profile Steel Drywall for ceiling structure

- Q: Shanghai light steel keel ceiling, wall quotes

- Depends on the use of good and bad materials. Ordinary ceiling also 30-40, partition 35-45, I was doing this is what the project. Can contact me. Offer

- Q: Light steel keel wall circuit how to wear pipe

- Install the crossed keel (lower threshold). Fixed with a nail, or first drilling, and with the expansion bolts connected to fixed. Installation should be installed according to the center line and edge, both ends of the top to the structural wall (column) surface, the final fixed point from the structure of the facade should not be greater than 100mm; nail or expansion bolt spacing should not be greater than 800mm. Installation should ensure that the keel level and straightness.

- Q: Home improvement in the partition

- Light steel keel, wood keel wall: light steel keel is a substitute for wood keel products, fire effect is significant (when using wood keel to brush fire retardant coating). As a partition wall of the external use of the plate there are gypsum board, Ed panels and aluminum-plastic panels, according to the actual requirements. If you want to do noise effects, in the middle of the installation of rock wool or mineral wool sound-absorbing panels;

- Q: Waterproof gypsum board for toilet partition and paste tile installation steps?

- Bathroom wall on the calcium silicate board filled with less than 3CM steel mesh; fixed with a code nail gun; and then use 1: 3 of the cement mortar smear 2-3CM thick. After leveling the hair according to the normal process of paving wall.

- Q: Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- Light steel keel life in humid environment Short brick block from the weight of large but because the single volume of small transport more convenient light partition board can be used for humid environment but a single volume upstairs is not convenient to install as light steel keel convenience The cost gap is not big

- Q: Light steel keel partition wall door how to do

- On the light rail keel at the door, apply one or two layers (at least one of the two sides of the upper hinge) to the joinery board - to ensure that the weight of the hinge carrying the door firm.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- 1, the main structure is completed, before the ceiling, the first wall construction. 2, light steel keel installation is completed, should be based on the construction acceptance of the keel for acceptance, such as skeleton does not meet the requirements, should be promptly adjusted. 3, the installation of gypsum board must be stress-free installation, first with self-tapping nail fixed gypsum board center parts, and then fixed the edge, so that the gypsum board after installation without any stress.

- Q: How to construct double - sided double gypsum board partition wall

- Line: according to the design and construction plans, in accordance with the keel width of the elastic line, has been done on the ground or ridge to release the wall position line, door and window openings border line, and put the top, wall keel position edge. To cover the panel of the long, wide sub-file, to ensure that the keel position is correct. Heaven and earth keel installation, along the ball line fixed top, to keel, fixed point spacing should not be greater than 600mm, keel docking should remain straight. Fixed keel keel, keel the end should be fixed, fixed should be solid. Wall, column edge keel with nails or wood screws and walls, column fixed, nail distance of 1000mm.

- Q: How to do woodworking partition wall, with door

- Wood keel partition wall is made of red, white pine do skeleton, gypsum board or wood fiber board, plywood for the panel of the wall, its processing speed, low labor intensity, light weight, sound insulation effect is good, widely used.

- Q: Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Focus on the ground material, the first floor of the plant decoration if the ground, a lot of plant floor decoration is not required to carry the load, then you can consider using some inexpensive decorative materials, such as terrazzo or cement flooring to do the plant floor decoration materials, Decoration to consider anti-static, then we should choose anti-static floor or anti-epoxy floor, etc. as the preferred material for the ground, there are plant floor decoration needs to load the ground, then we must do concrete in the ground floor, Concrete is divided into commercial concrete and soil concrete two, the former cost slightly higher but the quality is stable, the latter price lower quality in general, and then in the concrete base and then lay the other texture is more hard stone finishes can be.

Send your message to us

Cold formed Profile Steel Drywall for ceiling structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords