Coil Aluminum Sheet for PP Caps 1100 3003 Coated Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

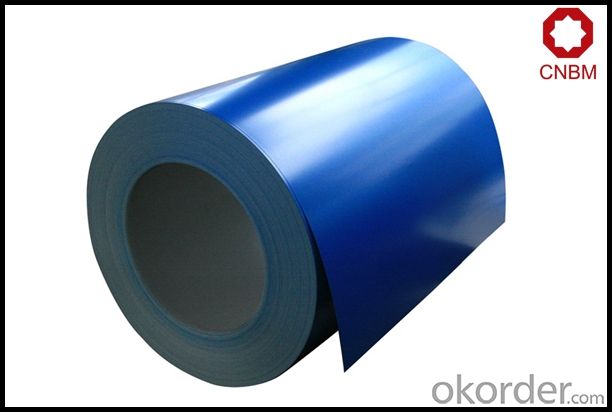

1. Specification of Coated Aluminum Coil for PP Caps 1100 3003

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Coated Aluminum Coil for PP Caps 1100 3003

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Coated Aluminum Coil for PP Caps 1100 3003

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Coated Aluminum Coil for PP Caps 1100 3003

6. Package and shipping of Coated Aluminum Coil for PP Caps 1100 3003

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the cost-effectiveness of using aluminum coils in the long run?

- The use of aluminum coils in the long term can yield significant cost-effectiveness. Despite the initial higher cost compared to materials like copper, aluminum coils offer long-term advantages that make them a wise choice. To begin with, aluminum coils exhibit exceptional resistance to corrosion, which means they are unlikely to deteriorate over time. Consequently, they have a longer lifespan and require less maintenance, resulting in reduced costs. Additionally, aluminum coils possess high heat transfer efficiency, enhancing energy efficiency and lowering energy consumption. Moreover, aluminum is a lightweight material, making it more economical and easier to transport and install compared to heavier alternatives. This leads to reduced labor costs during installation or replacement. Another factor that enhances the cost-effectiveness of aluminum coils is their recyclability. Aluminum is highly recyclable, and the scrap value of aluminum coils can offset the initial investment. Furthermore, the use of recyclable materials aligns with sustainability objectives and can contribute to a positive brand image and reputation. In summary, despite the higher upfront cost, aluminum coils offer long-term benefits such as corrosion resistance, energy efficiency, recyclability, and reduced maintenance and labor costs. Consequently, they are a cost-effective choice in the long run.

- Q: Is there any specific legislation or rules governing the use of aluminum coils in public areas?

- <p>There are no universal special regulations for using aluminum coils in public places. However, regulations can vary by country, state, or even city. In some cases, building codes or safety regulations might dictate the use of certain materials, including aluminum coils, in construction or other applications within public spaces. It's important to check local regulations and guidelines to ensure compliance when using aluminum coils in public areas.</p>

- Q: What are the benefits of using aluminum coils?

- There are several benefits of using aluminum coils. Firstly, aluminum is a lightweight material, making it easier to handle and install. Secondly, aluminum is highly resistant to corrosion, ensuring the durability and longevity of the coils. Additionally, aluminum coils have excellent heat transfer properties, allowing for efficient cooling or heating. Lastly, aluminum is a sustainable and recyclable material, making it an environmentally friendly choice.

- Q: Explain the key differences between aluminum coil and steel coil, including material properties and applications.

- <p>Aluminum coil and steel coil are distinct based on their material composition and properties. Aluminum coil is made from aluminum, a lightweight metal known for its corrosion resistance, high thermal and electrical conductivity, and formability. It is commonly used in applications such as packaging, construction, and electrical components. Steel coil, on the other hand, is made from steel, a stronger and more durable metal that offers greater tensile strength and is more resistant to deformation. Steel is widely used in construction, automotive, and manufacturing due to its strength and durability. The choice between aluminum and steel coil depends on the specific requirements of the application, such as weight, strength, and cost considerations.</p>

- Q: This question asks for a comparison between aluminum coil and other types of wire, highlighting their differences.

- <p>Aluminum coil is a type of wire made from aluminum, known for its lightweight, high conductivity, and corrosion resistance. It's commonly used in electrical applications, construction, and packaging. Other types of wire, such as copper wire, have different properties. Copper, for instance, has higher conductivity than aluminum but is heavier and more expensive. Steel wire is stronger and more durable but less conductive and prone to rust. The choice between aluminum coil and other wires depends on the specific requirements of strength, conductivity, cost, and environmental resistance for the application in question.</p>

- Q: Can aluminum coils be used for radiation shielding?

- Indeed, radiation shielding can be accomplished using aluminum coils. Owing to its substantial atomic number and density, aluminum is frequently employed as a radiation shielding material, demonstrating remarkable proficiency in absorbing and dispersing radiation. It effectively safeguards against an extensive spectrum of radiation varieties, encompassing gamma rays and X-rays. Moreover, aluminum possesses the advantageous qualities of being lightweight and pliable, rendering it convenient to manipulate and appropriate for a wide range of situations necessitating radiation shielding. These encompass domains such as medical imaging, nuclear power plants, and the aerospace industry.

- Q: Are aluminum coils suitable for heat exchangers?

- Yes, aluminum coils are suitable for heat exchangers. Aluminum has excellent thermal conductivity, corrosion resistance, and lightweight properties, making it an ideal material for heat transfer applications. Aluminum coils can efficiently transfer heat between fluids in heat exchangers, making them a popular choice in various industries.

- Q: I know when you stick weld aluminum you're more brazing than actually welding but i was just wondering about this, i want some electrodes just in case i need a temporary repair. Also what Amperage should i run it at,and what polarity?? my friend told me to run hotter than usual but hes only 14, and I dont know how reliable he is. Im 14 by the way also and have been welding for two years now and im always out running around the ranch doing small repairs. thanks ahead of time!

- Aluminum will oxidize quickly when it is heated in the air. You must have an inert gas around the weld when you are working it. A wire feed or T I G system is better than a stick machine. I suggest you do a lot of reading about aluminum and how to it is welded before you buy any tools. For small repairs that do not require much strength J B Weld will work.

- Q: Does anyone know of any men's deodorant that doesn't contain aluminum? It has to be strong, as I do sweat a lot.

- Deodorants Without Aluminum For Men

- Q: Can aluminum coils be used in the production of fire-resistant structures?

- Yes, aluminum coils can be used in the production of fire-resistant structures. Aluminum has a high melting point and excellent thermal conductivity, making it suitable for applications where fire resistance is required. Additionally, aluminum does not burn and can help to prevent the spread of fire, making it a popular choice for fire-resistant structures such as fire doors, fire-resistant walls, and fireproof insulation.

Send your message to us

Coil Aluminum Sheet for PP Caps 1100 3003 Coated Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords