Wide Aluminum Roof Coil - Coated and Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Coated Aluminum Coil /Prepainted Aluminum Coil

l Product Information

1 | Alloy: | A1100, A1050, A1060,A3003, A3004, A3005, A3105 , A5052, , A5754, A8011 etc. |

2 | Temper: | H14, H16, H18, H24 etc. |

3 | Thickness: | 0.2mm - 2.0mm |

4 | Width: | 15mm - 1600mm |

5 | Color: | chromic,white,metallic and so on(Customized, choose from RAL color chart or refer to customers' counter sample.) |

6 | Coating: | Polyester(mainly),Fluorocarbon(mainly),polyurethane and epoxy coating ect. |

7 | Coating thickness: | PVDF≥25 micron; PE≥18 micron. |

8 | Surface Quality: | be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use. |

9 | Mechanical Property: | Chemical Composite and Mechanical Property are meted with GB/T, ASTM, ENAW Standard. |

10 | Interior diameter: | 105mm or 405mm or 505mm |

11 | Coating hardness: | (pencil hardness) more than 2H |

12 | Impact resistance: | no cracking and peeling(≥50kg/cm) |

13 | Flexibility(T-bend) : | ≤ 2T |

14 | MEK resistance: | more than 100 |

15 | Application: | roofs, facade cladding, ceilings, aluminum curtains, composite panels, pipe wrap, advertisement plates, instrument panels, and other uses. |

l Product Information

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payment.

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is a popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality aluminium coil to the world.

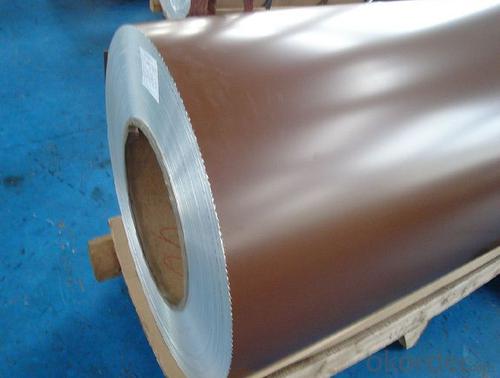

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What is the role of aluminum coils in the construction of ships?

- Aluminum coils play a crucial role in the construction of ships, particularly in the marine industry. These coils are used to manufacture various components and structures that are essential for shipbuilding. One of the main advantages of using aluminum coils in ship construction is their lightweight nature. Aluminum is significantly lighter than traditional steel, which allows for increased fuel efficiency and better overall performance of the ship. This is particularly important for larger vessels, as reducing weight helps to minimize energy consumption and operating costs. Additionally, aluminum coils offer excellent corrosion resistance, making them ideal for the marine environment. Ships constantly face exposure to saltwater, which can be highly corrosive to metals. By using aluminum coils, shipbuilders can ensure that their vessels are better protected against rust and corrosion, ultimately increasing their lifespan and reducing maintenance requirements. Moreover, aluminum coils can be easily shaped and formed into various structures, offering greater design flexibility for shipbuilders. This versatility allows for the creation of complex and intricate ship components, such as hulls, superstructures, and bulkheads. Aluminum's excellent weldability also makes it easier to join different sections of the ship together, resulting in a more efficient and streamlined construction process. Furthermore, aluminum is a highly sustainable material. It is 100% recyclable, meaning that it can be reused without any loss in quality or performance. This makes aluminum coils an environmentally friendly choice for ship construction, aligning with the increasing emphasis on sustainability in the industry. In summary, the role of aluminum coils in ship construction is multifaceted. They provide lightweight, corrosion-resistant, and easily formable materials that contribute to improved fuel efficiency, durability, and design flexibility. Moreover, their recyclability makes them an environmentally conscious option. Overall, aluminum coils are a vital component in building ships that are efficient, durable, and sustainable.

- Q: This question asks for methods to determine the age of an aluminum coil, distinguishing between new and old.

- <p>To determine if an aluminum coil is new or old, you can look for several indicators: the surface condition, such as scratches or signs of wear; the quality of the protective coating, if any, which may degrade over time; the manufacturing date or batch number, if available; and the overall appearance and shine. New coils typically have a smooth, shiny surface with no significant scratches or dents, and a consistent protective coating. Old coils may show signs of oxidation, discoloration, or other forms of degradation. Additionally, testing the coil's physical properties, such as tensile strength, can provide clues about its age, as these properties can degrade over time.</p>

- Q: Can aluminum coils be used in the production of aluminum louvers?

- Yes, aluminum coils can be used in the production of aluminum louvers. Aluminum coils are typically used as a raw material in various manufacturing processes, including the production of aluminum louvers. They can be easily formed and shaped into the desired louver design, offering durability and corrosion resistance.

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

- Q: What are the different surface treatments applied to aluminum coils?

- There are several different surface treatments that can be applied to aluminum coils to enhance their appearance, protect against corrosion, and improve their overall performance. Some of the most common surface treatments for aluminum coils include: 1. Anodizing: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum. This treatment enhances the corrosion resistance of the coils and provides a decorative finish. Anodized aluminum coils are available in a wide range of colors and finishes. 2. Painting: Painting is a surface treatment that involves applying a coating of paint to the aluminum coils. This treatment provides a decorative finish and can also enhance the corrosion resistance of the coils. Painted aluminum coils are commonly used in architectural applications where aesthetics are important. 3. Laminating: Laminating is a process that involves applying a thin layer of protective film to the surface of the aluminum coils. This treatment provides a protective barrier against scratches, abrasion, and UV radiation. Laminated aluminum coils are often used in applications where durability and weather resistance are important. 4. Polishing: Polishing is a mechanical process that involves buffing the surface of the aluminum coils to create a smooth and shiny finish. This treatment enhances the appearance of the coils and can also improve their corrosion resistance. Polished aluminum coils are commonly used in decorative applications where a high-end look is desired. 5. Brushing: Brushing is a mechanical process that involves creating a pattern of fine parallel lines on the surface of the aluminum coils. This treatment gives the coils a brushed or satin finish and can also help to hide imperfections and scratches. Brushed aluminum coils are often used in applications where a modern and sleek appearance is desired. Overall, the choice of surface treatment for aluminum coils depends on the specific application requirements and desired aesthetic. Each treatment offers unique benefits in terms of appearance, corrosion resistance, and durability, allowing manufacturers and designers to select the most suitable option for their needs.

- Q: What are the different types of surface treatments for aluminum coils?

- There are various types of surface treatments available for aluminum coils, including anodizing, painting, laminating, and chemical conversion coating.

- Q: Are aluminum coils suitable for food storage containers?

- Yes, aluminum coils are suitable for food storage containers. Aluminum is a popular material choice for food storage containers due to its various advantageous properties. Firstly, aluminum is lightweight, making it easy to handle and transport. Additionally, aluminum has excellent thermal conductivity, which means it can cool down or heat up quickly, making it ideal for both hot and cold food storage. Moreover, aluminum is resistant to corrosion and does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain intact. Furthermore, aluminum is a sustainable and recyclable material, making it environmentally friendly. However, it is important to note that aluminum containers should be lined with a food-grade coating to prevent any potential reaction between the metal and the food, especially acidic foods. Overall, aluminum coils are a suitable choice for food storage containers due to their lightweight nature, thermal conductivity, corrosion resistance, and recyclability.

- Q: Can aluminum coils be recycled multiple times?

- Aluminum coils possess the remarkable ability to be recycled numerous times. This is due to the fact that aluminum is an exceptionally recyclable substance, and its quality remains unaltered throughout the recycling process. As a result, aluminum coils can be melted and reshaped into fresh coils on multiple occasions, without experiencing any deterioration in their performance or characteristics. The act of recycling aluminum not only aids in the preservation of natural resources, but it also conserves a significant amount of energy compared to the production of new aluminum using raw materials. Consequently, opting for aluminum coils is a sustainable and eco-friendly decision, as they can be recycled multiple times.

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Yes, aluminum coils are generally more cost-effective compared to other materials like copper. There are several reasons for this. Firstly, aluminum is a more abundant metal than copper, which makes it cheaper to produce. This abundance also means that aluminum prices tend to be more stable and less prone to fluctuations in the market, further contributing to its cost-effectiveness. Secondly, aluminum coils have a lower density compared to copper coils, resulting in lighter weight units. This lighter weight not only reduces transportation and installation costs but also makes aluminum coils easier to handle and maneuver during the manufacturing process. Additionally, aluminum coils have excellent thermal conductivity properties, which means they can effectively transfer heat. This allows for more efficient cooling or heating systems, resulting in lower energy consumption and operating costs over time. Moreover, aluminum has a higher resistance to corrosion compared to copper, making it more durable and requiring less maintenance. This increased lifespan of aluminum coils reduces replacement and repair costs, further enhancing their cost-effectiveness. Lastly, aluminum coils are recyclable, and the recycling process requires significantly less energy compared to producing new aluminum. This aspect contributes to the overall sustainability and cost-effectiveness of aluminum coils. Overall, considering the lower production costs, lighter weight, superior thermal conductivity, increased durability, and recyclability, aluminum coils are indeed more cost-effective compared to other materials like copper.

- Q: What benefits can utilizing aluminum coil bring to the construction industry?

- <p>Aluminum coil offers several advantages in construction, including its lightweight nature which reduces structural load and facilitates easier handling and installation. It is highly resistant to corrosion, ensuring longevity and low maintenance costs. The material is also known for its excellent thermal conductivity, making it suitable for energy-efficient applications. Additionally, aluminum coil is recyclable, contributing to sustainability and reducing environmental impact. Its versatility allows for various applications, from roofing and siding to structural components, enhancing aesthetic appeal and functionality.</p>

Send your message to us

Wide Aluminum Roof Coil - Coated and Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords