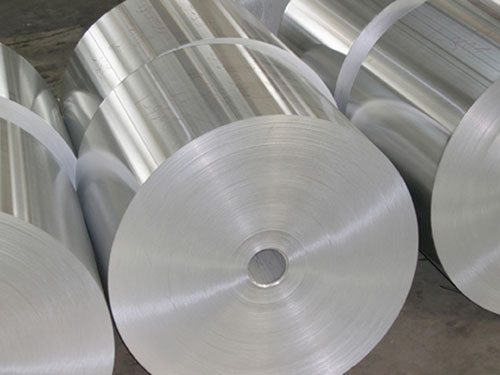

Aluminum 20mic Blister Packing Aluminum Foil 8011-H18 - 0.021mm

- Loading Port:

- CN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 7000MT m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

8011 blister aluminum foil for medicine packing:

OP/Printing/ALU/HSL

Thickness:20-25micron

Length:1000mm

8011 blister aluminum foil for medicine packing :

Applications: Blister packages for Pharmaceuticals products such as capsules, tablets, pill , pastille, small-size food , candy, etc.

Structure and application:protect layer (OP)/Outer printing layer/Aluminum foil based material (AL) inside printing layer/Bond (VC). Use in drugs blister packaging machine.

Performance and the characteristic: Excellent properties such as of anti- oxygen, moisture-proof, leak-proof,carryhome, antipollution, etc. Adopting hard anodized aluminum as cover material, it is easy to break aluminum foil to take out the drugs by pushing the cover. Adopting heat-seal coating material, which cannot be stripped,it can be bonded with all kinds of plastic-based materials.

According to printing method:

plain foil(no printing), printing foil (one-sided printing, two sided printing,single color print,double color printing, polychrome printing), color foil (one-sided golden color, two sided golden color,green bottom color,each kind of colored bottom color), forgery-proof (stealth writing, design, positive and negative printing).

Product shape: roll material.

Structures : OP (Protective layer) / Print Layer/ AL(Aluminum layer)/VC(agglutinate layer)

Specification:

Width: less than 1000mm,

Thickness: 0.02 to 0.025mm

Inner hole diameter : 76mm/152mm,

Outer diameter: 240-280mm, Length/roll:1000mm-2000mm (according to different requirement). One side is for sealing with pvc or pvc/pvdc film and other side is for printing.one side is bright and other side is dull.

Functions: High obstruction, Heat insulation, Air tightness, Printable, Breakable in slightly.

Characters: Our goods are well sealed for pinholes, coating is average with heat insulation, print is clear and beautiful with shining.

Applications: it can be applied to blister packing for capsules, pills, suppositories and mini-foods/candies, chocolate, chutty and so on.

Packing:each roll to be wrapped with sack polyethylene.outer packing:carton packing,wrap by film then pallet packing.

Why Us:

• More than 10 years experience, USD 800 million sales every year.

•Good quality control in production process,

• Excellent quality and Competitive price, OEM is available.

• Available in an extensive range of stock or custom size.

• Any port in China available.

• MOQ can meet your promotional business very well.

Trade Terms:

• Payment: T/T 30% in advance, balance against copy of B/L,Western Union.

• Production Lead Time: 5-7 after deposit paid.

• Shipping Methods: Oean carriage

• If you want to deal with EXW/CIF/CNF term instead of FOB, please specify. Otherwise, FOB price will be quoted under inquiry.

Our Service:

• Your inquiry related to our product & price will be replied within 24hours.

• Well-trained & experienced staff are to answer all your inquiries professional in English of course.

• Working time: 8:30am - 17:30pm, Monday to Saturday (UTC+8).

• OEM is highly welcomed. We have strong R&D team here to help.

• Your business relationship with us will be confidential to any third party.

• Good after-sale service offered, please get back if you got question.

Suggestion:

Please kindly check the packages after you receive the goods, if you got wrong products/ quality problem/ short q'ty, please get back to us as priority. Please note that you need to send us pictures of the defective items concerning this, and we will consider to replace or refund accordingly.

- Q: Is it possible to recycle aluminum using renewable energy sources such as solar or wind power?

- <p>Yes, aluminum can be recycled using solar energy or wind energy. The recycling process involves melting the aluminum, which can be powered by electricity generated from renewable sources. Solar panels and wind turbines can produce the electricity needed for this process, reducing the carbon footprint associated with aluminum recycling. In fact, recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials, making it an energy-efficient process that benefits significantly from renewable energy sources.</p>

- Q: This question asks for methods to effectively clean aluminum surfaces without causing damage.

- <p>To clean aluminum surfaces effectively, use a mild detergent and warm water. Mix a few drops of dish soap with water in a bucket. Dip a soft cloth or sponge into the solution and gently wipe the aluminum surface. Avoid using abrasive materials or harsh chemicals, as they can scratch the surface. After cleaning, rinse with water and dry thoroughly to prevent water spots. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. Regular cleaning will help maintain the surface's appearance and prevent corrosion.</p>

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a roofing material.

- <p>Advantages of using aluminum sheets for roofing include their lightweight nature, which reduces structural load; corrosion resistance, making them suitable for coastal areas; and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Disadvantages include the potential for dents and damage from hail or heavy impacts, and they can be more expensive than some other roofing materials. Additionally, aluminum can be noisy during rain, and it may require more frequent replacement compared to some other materials due to its lighter gauge.</p>

- Q: This question asks about the typical issues that arise due to the corrosion of aluminum.

- <p>Common problems with aluminum corrosion include loss of structural integrity, which can compromise the safety and performance of aluminum components. Corrosion can lead to a decrease in mechanical strength, increased brittleness, and a reduction in the electrical and thermal conductivity of aluminum. Additionally, aesthetic issues such as discoloration and pitting can occur, affecting the appearance of aluminum surfaces. Environmental factors and improper handling can accelerate corrosion, leading to costly repairs or replacements.</p>

- Q: What are the sustainable methods that can be employed in the manufacturing process involving aluminum?

- <p>Yes, sustainable methods can be employed in aluminum manufacturing. These include using recycled aluminum, which requires significantly less energy than mining and refining new aluminum. Implementing energy-efficient technologies and reducing emissions in the production process are also crucial. Additionally, investing in research for new, more sustainable aluminum alloys and manufacturing processes can lead to reduced environmental impact. Lastly, proper waste management and recycling programs can help minimize the environmental footprint of aluminum production.</p>

- Q: Is there an alternative method for recycling aluminum besides the conventional recycling process?

- <p>Yes, aluminum can be recycled in different ways. Apart from the conventional recycling process, which involves melting and recasting, there are innovative methods being explored. One such method is mechanical recycling, where aluminum is cleaned, sorted, and processed into new products without melting. Another approach is chemical recycling, which breaks down aluminum into its constituent elements and then reassembles them into new materials. These alternative methods aim to reduce energy consumption and environmental impact while still effectively recycling aluminum.</p>

- Q: The question seeks to understand the steps involved in producing aluminum, from raw material extraction to the final product.

- <p>The process of aluminum production involves several key steps. Initially, bauxite, the primary aluminum ore, is mined. This ore is then crushed and washed to remove impurities. The next phase is the Bayer Process, where bauxite is dissolved in a caustic soda solution under high temperature and pressure, resulting in a solution rich in aluminum hydroxide. This solution is then seeded with aluminum hydroxide crystals, causing more crystals to form, which are then harvested. The final step is the Hall-H茅roult Process, where the aluminum oxide is dissolved in a molten cryolite bath and electrolyzed to extract pure aluminum. This process involves passing an electric current through the bath, causing aluminum ions to be reduced at the cathode, forming molten aluminum which is then tapped off for further processing or use.</p>

- Q: Is it safe to use aluminum for making containers for food and beverages?

- <p>Yes, aluminum can be used to make containers for food and drink. Aluminum is a common material for food packaging due to its lightweight, durability, and resistance to corrosion. It forms a protective oxide layer that prevents the metal from interacting with the food, ensuring safety. However, it's important to note that aluminum containers should not be used for storing acidic foods or beverages for extended periods, as this can lead to leaching of aluminum into the food. Additionally, some studies suggest a potential link between aluminum and neurological disorders, though this is still a subject of debate.</p>

- Q: Explain the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in building materials due to its lightweight, high strength, and corrosion resistance. It's utilized in window frames, doors, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum's malleability allows it to be shaped into various forms, making it ideal for facades and decorative elements. It's also used in structural components like beams and columns, and in electrical wiring due to its excellent conductivity. Additionally, aluminum's sustainability makes it a preferred choice in green building practices, as it's recyclable and has a low environmental impact.</p>

- Q: This question asks for examples of how aluminum is used in architectural designs.

- <p>Aluminum is a versatile material in architecture due to its strength, light weight, and resistance to corrosion. Some examples include the Empire State Building's spire, which was originally clad in aluminum, and the Petronas Twin Towers in Kuala Lumpur, known for their aluminum and glass facade. The Guggenheim Museum in Bilbao features an aluminum-clad exterior, and the Beijing National Stadium, also known as the Bird's Nest, utilizes aluminum for its intricate lattice structure. Additionally, aluminum is commonly used in curtain walls, window frames, and roofing systems due to its durability and sustainability.</p>

Send your message to us

Aluminum 20mic Blister Packing Aluminum Foil 8011-H18 - 0.021mm

- Loading Port:

- CN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 7000MT m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords