Fiberglass Fabrics - Coated Fiberglass Fabric with Different Specifications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

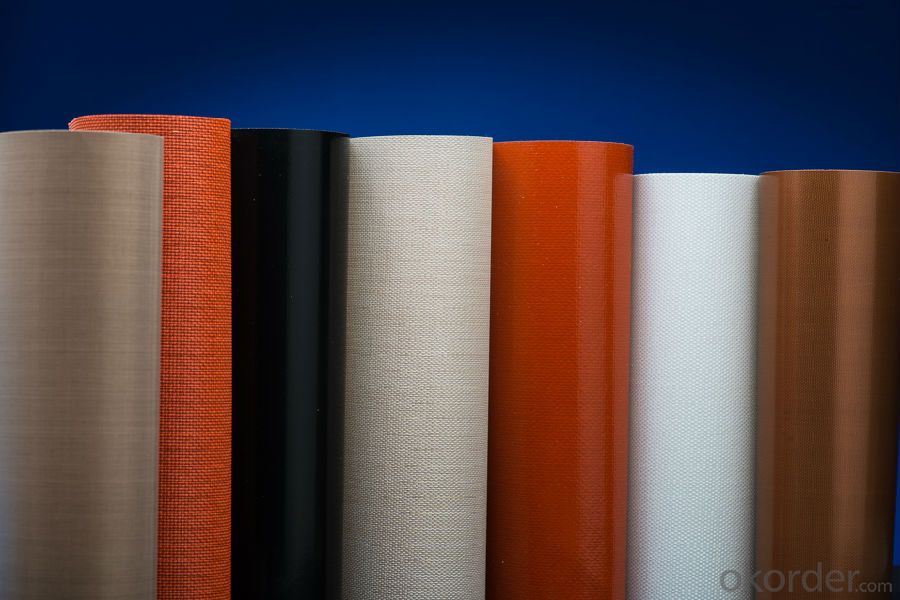

Coatecd Fiberglass Fabric with Different Specification

Fiberglass Fabric Description

Silicone coated fiberglass fabric are made of fine fiberglass with excellent capacity of high temperature and corrosion resistance, coated and rolled with silicone rubber, which is a brand new product with good performance and multiple applications.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

1) Electric insulation: it feature high grade of electric insulation and bear a load of high voltage. It fits for making products like insulation cloth and sleeves et.

2) Non - metalli compensator: used as pipeline oupling, non-metallic compensactor helps to avoid damage caused by heat expansion and cold contraction. This membrane material speially fit for using in industres of petroleum, chemical engineering, cement, iron and steel and good elasticity and toughness.

3)Anti-conrrosion sector: It is good to be used as inner and outer anti-corrosion layer featuring excellent corrosion resistance, tempareture resistance and high strength. It proves to be an ideal anti-corrosion material.

4) Others: Apart from above application, it can also be used as sealing material, temperature resistant and anti-orrosion conveyr belt and packaging material.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: What are the different fiberglass fabric weaves for high strength applications?

- There are multiple fiberglass fabric weaves commonly utilized for high strength applications, including plain weave, twill weave, satin weave, and leno weave. 1. Plain weave: This weave pattern is the most fundamental and widely used. It involves an over-under pattern, with each warp yarn passing over and under each weft yarn. Plain weave fabrics offer exceptional strength and dimensional stability, making them appropriate for a wide range of high strength applications. 2. Twill weave: Twill weave is characterized by a diagonal pattern formed by the interlacing of warp and weft yarns. This weave is renowned for its strength and durability. Twill weave fabrics possess good drapability, making them ideal for applications requiring flexibility and resistance to wrinkling. 3. Satin weave: Satin weave is identified by long floats, where the warp or weft yarns skip over multiple yarns in the opposite direction. This creates a smooth and glossy surface. Satin weave fabrics boast excellent strength and are commonly used in applications desiring a high-quality finish, such as aerospace components and luxury goods. 4. Leno weave: Leno weave is a distinctive pattern that involves twisting adjacent warp yarns around each weft yarn. This creates a stable and open structure with good strength and stability. Leno weave fabrics find common use in high strength applications where breathability and lightness are crucial, such as filtration systems and composites. These various fiberglass fabric weaves offer different levels of strength, flexibility, and durability, enabling manufacturers to select the most suitable weave for their specific high strength applications.

- Q: How is fiberglass fabric cleaned?

- To easily clean fiberglass fabric, you can follow some simple procedures. Begin by eliminating any loose dirt or debris from the fabric through vacuuming or gently brushing. For general cleaning, create a mixture of mild detergent and warm water. Proceed to gently scrub the fabric using a soft brush or sponge, ensuring that all areas are covered evenly. It is advised to avoid harsh chemicals or abrasive materials, as they could potentially harm the fabric. Once you have finished scrubbing, thoroughly rinse the fabric with clean water to eliminate any soap residue. Lastly, allow the fabric to completely air dry before using it again. By adhering to these steps, you will effectively maintain the cleanliness and durability of your fiberglass fabric.

- Q: Magnesite material instability made sheds or greenhouse skeleton for a few years

- Magnesite cement is gas cementing material, special environmental requirements, magnesite greenhouse scaffold has good water resistance, namely: in the long-term high temperature and humidity strength is not decreased; at the same time magnesite cement in magnesium chloride is harmful to the crops, so the firm can not back to the brine magnesite greenhouse bracket. Through scientific modification technology and reasonable production process, we have effectively solved these technical problems.

- Q: Is fiberglass fabric resistant to chemicals used in pharmaceutical industry?

- Yes, fiberglass fabric is generally resistant to the chemicals used in the pharmaceutical industry. Its non-reactive nature and high chemical resistance make it suitable for use in various pharmaceutical applications such as filtration, insulation, and protective clothing. However, it is important to note that the specific chemical resistance may vary depending on the type of fiberglass fabric and the concentration and duration of exposure to the chemicals.

- Q: Is fiberglass fabric resistant to chemicals in swimming pools?

- Fiberglass fabric is known for its ability to resist chemicals typically found in swimming pools. It is a strong and durable material that is often used in constructing swimming pools because of its exceptional resistance to chemicals. Fiberglass can withstand chlorine, bromine, and other commonly used pool water treatments without being damaged. This resistance allows fiberglass fabric to maintain its strength and appearance, making it an excellent choice for pool linings, covers, and other applications exposed to pool chemicals. However, it's important to note that prolonged exposure to highly concentrated or extremely harsh chemicals may eventually cause some degradation or discoloration of the fiberglass fabric. Therefore, regular maintenance and proper care are crucial to ensure the long-lasting performance of fiberglass fabric in swimming pool environments.

- Q: How does fiberglass fabric handle vibration in automotive applications?

- Fiberglass fabric is known for its excellent vibration resistance in automotive applications. Its high tensile strength and flexibility help absorb and dampen vibrations, improving overall vehicle stability and reducing noise. Additionally, the lightweight nature of fiberglass fabric ensures minimal added weight to the vehicle, making it an ideal choice for vibration control without compromising performance.

- Q: Can fiberglass fabric be used for making protective sleeves?

- Yes, fiberglass fabric can be used for making protective sleeves.

- Q: Can fiberglass fabric be used for electrical cables?

- No, fiberglass fabric cannot be used for electrical cables.

- Q: How is fiberglass fabric used in the production of geotextiles?

- Fiberglass fabric is used in the production of geotextiles as a reinforcement material. It provides strength and stability to the geotextile, enabling it to withstand high tensile forces and enhance its durability. The fiberglass fabric is typically incorporated into the geotextile through lamination or needle-punching techniques, creating a composite material that can effectively prevent soil erosion, reinforce slopes, and provide separation and filtration functions in various civil engineering applications.

- Q: What is the average thickness of fiberglass fabric?

- The average thickness of fiberglass fabric typically ranges between 0.2 to 0.5 millimeters.

Send your message to us

Fiberglass Fabrics - Coated Fiberglass Fabric with Different Specifications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords