Cnc Machining Turning Aluminium drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

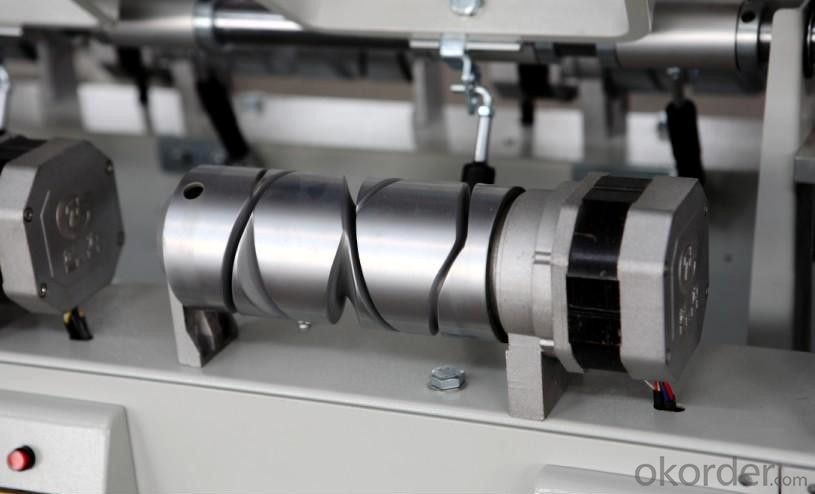

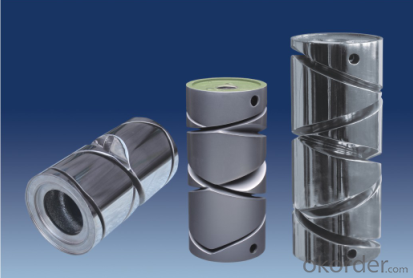

Cnc Machining Turning Aluminium drum of Winding Machine Parts

Adavantages:

Cnc Machining Turning Aluminium drum of Winding Machine Parts has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

Pictures shows of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

Models of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

· Q:What is the machine used for?

A:Cnc Machining Turning Aluminium drum of Winding Machine Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: Why the first industrial revolution in the cotton textile industry innovation will cause the British national yarn shortage?

- In 1733, a cotton weaving workshop mechanic Kai Yi invented the shuttle. Kay has been a watchmaker, skilled mechanical technology. He put some of the clocks in the process and process skills applied to the hand loom, and finally invented the shuttle this new weaving tool. A shuttle with a shuttle is actually an automatic shuttle loom that is more than double the efficiency of the original loom - although its driving force is still manpower

- Q: What is the second-hand textile machinery import clearance process?

- 1. Used equipment, but to maintain its basic use value or the full use value

- Q: What is the current status of the textile industry?

- China is the textile production and export power, China's textile industry itself after years of development, competitive advantage is very obvious, with the world's most complete industrial chain, the highest level of processing support, many developed industrial clusters to deal with market risk self-regulation The ability to continuously enhance the industry to maintain a steady pace of development provides a solid guarantee.

- Q: When did Chinese ancient textile technology come from? Why does Europe call China "silk country"?

- The world's first degumming linen - Gaocheng Taixi Shang Dynasty ruins of linen fragments, is currently found in the world's first artificial degumming linen. The expert identification, hemp yarn in the gum content is very small

- Q: What are the main producing areas of Chinese textile machinery?

- China's textile machinery industry base is located in Jiaonan City, Shandong Province, Wang Taizhen and Shanxi Province, Jinzhong City (Yuci District), the following is the town of Jiaonan City, Shandong Province, Wang Taizhen textile machinery industry status and Shanxi Province Jinzhong City (Yuci District) Introduction of Textile Machinery Industry.

- Q: What is the history of the development of textile machinery?

- Human beings originally used natural fibers as raw materials for spinning and weaving, earlier than the invention of the text (see World Textile History, China Textile History).

- Q: Who invented Jenny spinning machine?

- In 1768, Hargreaves won the patent; by 1784, "Jenny machine" has increased to eight spindles. Four years later the United Kingdom has twenty thousand "Jenny machine".

- Q: What are the classification of textile machinery?

- 2. Spinning wheel

- Q: What modern textile machinery?

- Manufacturing the entire textile machinery plant dedicated equipment accounted for the proportion of the whole plant equipment, so under certain conditions can change the variety of production of other machinery.

- Q: China's textile industry prospects of printing and dyeing ?

- Foreign-funded enterprises in addition to the equipment for the Chinese market, but also a large number of exports, and even anti-sales back to the country of origin. China is moving from one of the largest textile machinery market demand to Asia Textile Machinery Manufacturing Center, and even the world textile machinery manufacturing center.

Send your message to us

Cnc Machining Turning Aluminium drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords