Automatic Rewinding Machine For Winding Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Automatic Rewinding Machine For Winding Yarn:

Automatic Rewinding Machine For Winding Yarn is used for winding yarns on cones.

Application:

Automatic Rewinding Machine For Winding Yarn is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

Main Features:

Automatic Rewinding Machine For Winding Yarn has the following advantages:

· High precision, highly polished, self-lubricating on surface, litter friction with yarn are our basic functions.

· Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

· High-tech in dealing with surface, and it makes our grooved drums have high wear resistance, corrosion resistance and makes sure the hardness of the groove and surface are the same.

Good forming and uniform linear density.

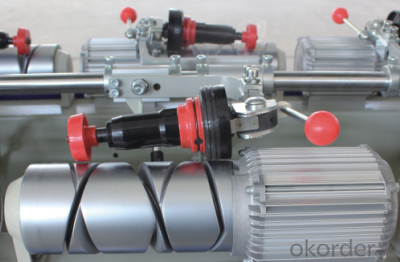

Images of Automatic Rewinding Machine For Winding Yarn:

Specification:

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 1200m/min (process speed depending on quality of yarn and feed packages) |

| Package shape | Cylindrical or conical packages |

| Traverse length | 147mm,150mm,154mm |

| External dimensions | 13410mm(length) ×700mm(width) ×1680mm(height) |

| Power supply | 3 phased 380V±10% ,50/60HZ |

| Automatic length fixing | Automatic length fixing,max:999999m |

FAQ of Automatic Rewinding Machine For Winding Yarn:

· Q:What is the machine used for?

A:Vertical Soft Yarn Winder is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What is a spinning wheel?

- Ancient general spinning machine according to the structure can be divided into hand-spinning and pedal spinning two.

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- From the 1738 AD 1779 to 40 years, spinning from manual production into a huge industrial manufacturing. In 1737 Paul (Paul) invented the roller-type spinning method, as many pioneers of the invention. In 1764, J. Hargreaves invented the machine (spinning Jenny), this machine can make sixteen spindles at the same time, in addition it can also operate in accordance with the order of multiple yarn The Subsequently, the spinning machines that refer to other power sources appear successively. AD 1769 Arkwright (R. Arfwright) was the help of watchmakers, improved old-fashioned spinning machine, invented the hydraulic spinning machine

- Q: What is the current domestic textile enterprises?

- Boshi Group Co., Ltd., Lutai Group, Inner Mongolia Ordos Cashmere Group Co., Ltd. Bosideng Co., Ltd., Lutai Group, Inner Mongolia Ordos Cashmere Group Co., Ltd.

- Q: What are the main producing areas of Chinese textile machinery?

- China's textile machinery industry base is located in Jiaonan City, Shandong Province, Wang Taizhen and Shanxi Province, Jinzhong City (Yuci District), the following is the town of Jiaonan City, Shandong Province, Wang Taizhen textile machinery industry status and Shanxi Province Jinzhong City (Yuci District) Introduction of Textile Machinery Industry.

- Q: What are the different effects of textile equipment?

- Clothing processing and finishing several major steps, before and after the equipment is no less than twenty units

- Q: What is the history of the development of textile machinery?

- 785 British E. Cartwright (also translated Edmund Carter Wright) invented the power loom, the same year the United Kingdom built the world's first steam-powered cotton textile mill, the textile industry from the workshop to the large industrial industry A turning point in the production transition. The progress of human society and the increase of population have promoted the development of textile industry and promoted the improvement of textile machinery accordingly. Energy reform (with steam instead of manpower, animal power) is laid the foundation of modern textile machinery.

- Q: Textile machinery points which six categories? What is the main role?

- Textile machinery is the natural fiber or chemical fiber processing into textiles required by the various mechanical equipment collectively

- Q: What are the related fields of textile engineering?

- With the basic skills of textile design and textile process design;

- Q: What is the task of preparing the process before spinning?

- The pressed raw cotton was loosened to about 0.1 mg of cotton

- Q: What is the historical background of the mechanization of the British cotton textile industry?

- Technology: Accumulation of workshop handicraft technology;

Send your message to us

Automatic Rewinding Machine For Winding Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords