Autoconer/espero/orian Grooved Drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

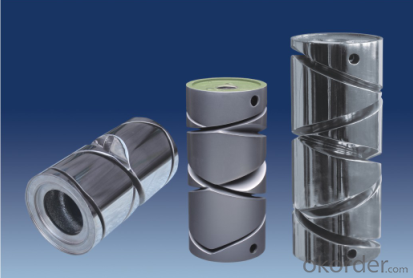

Autoconer/espero/orian Grooved Drum of Winding Machine Parts

Adavantages:

Autoconer/espero/orian Grooved Drum of Winding Machine Parts has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

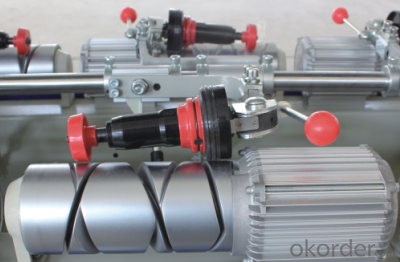

Pictures shows of Autoconer/espero/orian Grooved Drum of Winding Machine Parts:

Models of Autoconer/espero/orian Grooved Drum of Winding Machine Parts:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Autoconer/espero/orian Grooved Drum of Winding Machine Parts:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Autoconer/espero/orian Grooved Drum of Winding Machine Parts:

· Q:What is the machine used for?

A:Autoconer/espero/orian Grooved Drum of Winding Machine Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What is spinning down?

- The emergence of spinning has not only changed the original society of textile production, the development of later spinning tool is very far-reaching, and it as a simple spinning tool, has been used for thousands of years

- Q: What is a spinning wheel?

- Hand spinning wheel drive the power of the spinning wheel from the hand, the operation, need to shake the spinning wheel, hand in the spinning work

- Q: What are the general fixed assets of the textile industry?

- Polypropylene Spinning Machine, Polyester Spinning Machine, Polyester Spinning Machine, Polyester Spinning Machine

- Q: What is the current status of the textile industry?

- From the international environment, the international market is still a large expansion of space and opportunities. With the end of 2007, China and the EU textile limit expires, the end of 2008 the end of the Sino-US textile quota limit, the Chinese textile quota era is approaching, accounting for more than 60% of the global textile market share area is fully open, will bring to China's textile trade Great opportunity. And the next few years the world economy will remain in the rising range, will promote the growth of international trade, which will give China's textile and garment exports to bring favorable international market protection.

- Q: When the textile industry, as well as the history of the textile industry development?

- Ancient Chinese textile and printing and dyeing technology has a very long history, as early as in the primitive society, the ancients in order to adapt to climate change, has learned to take the land, the use of natural resources as textile and printing and dyeing raw materials, and the manufacture of simple textile tools. Until today, our daily clothing, certain daily necessities and works of art are the products of textile and printing and dyeing technology.

- Q: Textile equipment to protect the work is not a special type of work?

- First, the original State Administration of Labor "on the textile industry chemical fiber (viscose) toxic and hazardous operations early retirement job of the reply (81) Laojue Zi word 36) document, the following 13 types of toxic and hazardous special types of work: Carbon disulfide manufacturing, calcium sulphate liquid preparation workers, diggers, detergents, bleach, sulfonation, plate and frame filter workers, spinning workers, filament twist yarn and silk workers, filament head workers, filament Silk workers, cellophane manufacturing workers, iron chromium salt manufacturing workers.

- Q: Who invented Jenny spinning machine?

- 1768 J. Hargreaves in Nottingham joint venture with others to start a spinning workshop, with Jenny spinning machine production of knitted yarn. Because he did not apply for a patent, so only their own production "Jenny machine" to make money. "Jenny machine" is not only efficient, and the quality of spinning yarn is also better, so Hargreaves business is good, "Jenny machine" is also gradually spread out.

- Q: Why did the first industrial revolution begin with the sign of Jenny's textile machine rather than shuttle?

- The innovation of the British cotton industry began in 1733 when the mechanic John Kay found that the shuttle was the sign of the industrial revolution, but was narrow and limited to light industry.

- Q: What modern textile machinery?

- Manufacturing special spare parts factory-specific equipment, a large proportion of dedicated lines (especially knitting needles, clothing), change the species more difficult.

- Q: China's textile industry prospects of printing and dyeing ?

- Foreign-funded enterprises in addition to the equipment for the Chinese market, but also a large number of exports, and even anti-sales back to the country of origin. China is moving from one of the largest textile machinery market demand to Asia Textile Machinery Manufacturing Center, and even the world textile machinery manufacturing center.

Send your message to us

Autoconer/espero/orian Grooved Drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches