Accessories Yarn Grooved Drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

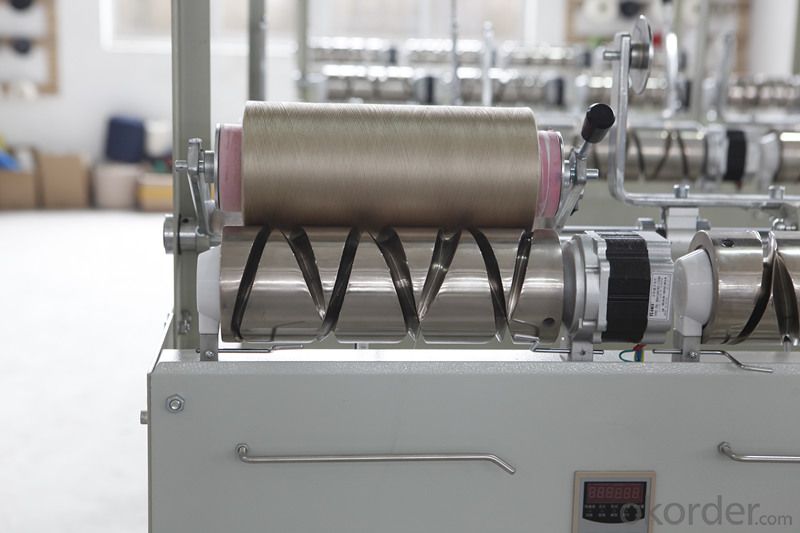

Accessories Yarn Grooved Drum

Adavantages:

Accessories Yarn Grooved Drum has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

Pictures shows of Accessories Yarn Grooved Drum:

Models of Accessories Yarn Grooved Drum:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Accessories Yarn Grooved Drum:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Accessories Yarn Grooved Drum:

· Q:What is the machine used for?

A:Vertical Soft Yarn Winder is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- The earliest use of hydraulic spinning machine is horsepower driven, and later cited hydraulic. The use of hydraulically operated machines is of great importance in the history of the textile industry, where textile workers can operate the machine at hand, but once the power is used, the worker can not leave the power source, As the beginning of the factory system. The first batch of factories in history was established to make textiles. In 1779, S. Crompton, in conjunction with the advantages of the Jenny spinning machine and the hydro spinning machine, developed a spinning mule that spun out fine and strong spun yarns,

- Q: What is a large hydraulic spinning wheel?

- To spar, for example, GM spinning up to 3 pounds per day spinning, and large spinning a day and night can be spinning more than 100 kilos. When spinning, it is necessary to use enough hemp to meet its production capacity

- Q: What are the general fixed assets of the textile industry?

- Polypropylene Spinning Machine, Polyester Spinning Machine, Polyester Spinning Machine, Polyester Spinning Machine

- Q: How to promote the textile machinery industry transformation and upgrading?

- From low production efficiency to high production efficiency, from the provision of product functionality

- Q: What are the risks of safety accidents in the textile machinery industry?

- The Fourth, in the exposed parts of the drive did not take security measures.

- Q: What is the history of the development of textile machinery?

- China in the Spring and Autumn Warring States have been using hand spinning spinning, to the Song Dynasty has been invented more than 30 spindle hydraulic large spinning wheel. 1769 British R. Akwright) (also translated Richard Ackerite) manufacturing hydraulic spinning machine.

- Q: Textile machinery points which six categories? What is the main role?

- Spinning equipment is divided into processing short fiber and processing long fiber two categories. Cotton and cotton chemical fiber short fiber, wool, linen, silk and its blended fiber long fiber. Two types of fiber processing processes are different, the equipment can not be universal, but some of the machine design principles are similar. Even if the same type of equipment, the structure of the machine is similar, but because of the nature of raw materials and the final requirements of the fabric is different, generally can not be universal.

- Q: What are the related fields of textile engineering?

- With the basic skills of textile design and textile process design;

- Q: What is the textile process?

- Spinning process mainly include: cotton, carding, combing, and bars, roving, spun yarn.

- Q: What is a pedal loom?

- The pedal loom is a generic term for a textile machine with a pedal

Send your message to us

Accessories Yarn Grooved Drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches