CNBM Stainless Steel Deformed Bars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CNBM Stainless Steel Deformed Bars with High Quality

Details of CNBM Stainless Steel Deformed Bars with High Quality

Name | Deformed Bar |

Shape | Round Bar |

Standard | 1.GB1499.2-2007, HRB335, HRB400E 2. ASTM A615 Gr.40, Gr.60 3.BS4449/1997 |

Diameter | 6mm-50mm |

Length | 6m, 8m, 9m,12m as standard or as request |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of CNBM Stainless Steel Deformed Bars with High Quality

Standard | Grade | Yield Strength Mpa | Tensile Strength | Elongation% |

BS4449:1997 | 250 | 250 | 295 | 22 |

460A | 460 | 485 | 12 | |

460B | 460 | 500 | 15 | |

GB1499.2-2007 | HRB335/335E | 335 | 455 | 17 |

HRB400/400E | 400 | 540 | 17 | |

HRB500/500E | 500 | 630 | 16 | |

ASTM A615 & A615M-04a | GRADE40 | 280 | 420 | 12 |

GRADE60 | 420 | 620 | 9 | |

GRADE75 | 520 | 690 | 7 | |

JIS G3112-2004 | SD295A | ≥ 295 | 440-600 | 17 |

SD295B | 295-390 | ≥ 440 | 17 | |

SD345 | 345-440 | ≥490 | 19 | |

SD390 | 390-510 | 560 | 17 | |

SD490 | 490-625 | ≥ 620 | 13 |

Size | WEIGHT | WEIGHT | QUANTITY | ||

LENGTH 6M | LENGTH 12M | LENGTH 6M | LENGTH 12M | ||

6 | 0.222 | 1.332 | 2.664 | 751 | 375 |

8 | 0.395 | 2.37 | 4.74 | 422 | 211 |

10 | 0.617 | 3.702 | 7.404 | 270 | 135 |

12 | 0.888 | 5.328 | 10.656 | 188 | 94 |

14 | 1.21 | 7.26 | 14.52 | 138 | 69 |

16 | 1.58 | 9.48 | 18.96 | 106 | 53 |

18 | 2 | 12 | 24 | 83 | 42 |

20 | 2.47 | 14.82 | 29.64 | 67 | 34 |

22 | 2.98 | 17.88 | 35.76 | 56 | 28 |

25 | 3.85 | 23.1 | 46.2 | 43 | 22 |

28 | 4.83 | 28.98 | 57.96 | 35 | 17 |

32 | 6.31 | 37.86 | 75.72 | 26 | 13 |

36 | 7.99 | 47.94 | 95.88 | 21 | 10 |

40 | 9.87 | 59.22 | 118.44 | 17 | 8 |

50 | 15.42 | 92.52 | 185.04 | 11 | 5 |

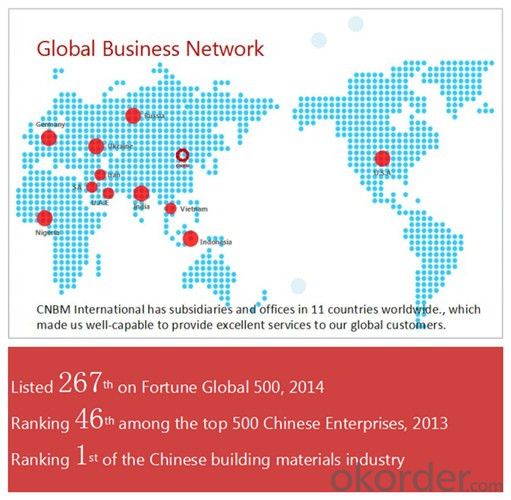

CNBM Introduction of CNBM Stainless Steel Deformed Bars with High Quality Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of CNBM Stainless Steel Deformed Bars with High Quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different processes involved in making special steel?

- The different processes involved in making special steel include melting and refining the raw materials, such as iron ore and scrap metal, in a furnace to create liquid steel. This liquid steel is then cast into various shapes using techniques like continuous casting or ingot casting. After casting, the steel undergoes heat treatment processes like annealing, quenching, and tempering to enhance its mechanical properties. Additionally, special alloying elements are added during the melting stage to give the steel specific characteristics, such as increased strength or corrosion resistance. Finally, the steel is finished by processes like machining, grinding, and polishing to meet the desired specifications and quality standards.

- Q: What are the main applications of special steel in the power distribution industry?

- Special steel is widely used in the power distribution industry for various applications. One of the main applications is in the construction of transmission towers and electrical pylons. Special steel is preferred for these structures due to its high strength, durability, and resistance to corrosion. It ensures the safe and reliable transmission of electricity over long distances. Special steel is also used in the manufacturing of electrical transformers and generators. The steel's magnetic properties make it suitable for creating efficient and reliable power generation and distribution equipment. Additionally, special steel is used in the production of electrical connectors and conductors, which are essential for ensuring the efficient flow of electricity through power distribution systems. Overall, the main applications of special steel in the power distribution industry include transmission towers, electrical pylons, transformers, generators, and electrical connectors. These applications play a crucial role in maintaining a robust and reliable power grid, ensuring uninterrupted electricity supply to consumers.

- Q: How does special steel contribute to the manufacturing industry?

- Special steel contributes to the manufacturing industry by providing superior strength, durability, and performance in various applications. Its unique composition and properties allow for the production of high-quality components and machinery that can withstand extreme conditions, ensuring safety and reliability. Additionally, special steel enables manufacturers to create lightweight and efficient products, leading to cost savings and environmental sustainability.

- Q: How does special steel contribute to the oil and gas equipment industry?

- Special steel plays a crucial role in the oil and gas equipment industry as it offers exceptional strength, corrosion resistance, and durability. It is used in the manufacturing of various critical components such as pipes, valves, fittings, and offshore platforms. Special steel's high heat resistance and ability to withstand extreme pressure and harsh environments make it an ideal choice for oil and gas equipment, ensuring reliability and safety in operations.

- Q: What are the main applications of special steel in the packaging industry?

- Special steel has a wide range of applications in the packaging industry, primarily due to its exceptional strength, durability, and corrosion resistance. It is commonly used in the manufacturing of packaging machinery, such as conveyor systems, filling machines, and cutting tools, ensuring efficient and precise operations. Additionally, special steel is often employed in the production of packaging materials, including cans, containers, and closures, providing enhanced protection and preservation of goods.

- Q: What are the different methods of surface electropolishing for special steel?

- Special steel can undergo surface electropolishing using various methods, each with its unique benefits and applications. 1. Immersion Electropolishing: To achieve a smooth and polished finish, the special steel components are immersed in an electrolyte bath, and a direct current is passed through the solution. This method is ideal for large and complex parts, offering uniform surface improvement on all exposed areas. 2. Electrolytic Electropolishing: By applying a direct current directly to the surface of the special steel component using an electrode, the surface dissolves, resulting in a reflective and smooth finish. This technique allows precise control over the process and is suitable for smaller or intricate parts, targeting specific areas that require improvement. 3. Reverse Pulse Electropolishing: A combination of direct and reverse current pulses is utilized to achieve an exceptional surface finish. The reverse current pulses reduce surface roughness and eliminate embedded particles or contaminants. This method is especially beneficial for special steel components that require enhanced corrosion resistance and improved cleanliness. 4. Magnetic Field-Assisted Electropolishing: Applying a magnetic field to the electropolishing process can enhance the polishing rate and surface finish. The alignment of the electrical current by the magnetic field improves material removal, resulting in a smoother and more uniform surface. This method is preferred for difficult-to-polish special steels or those with complex geometries. 5. Flow-Assisted Electropolishing: By using a flowing electrolyte solution, the electropolishing process is enhanced. The flowing solution aids in removing dissolved material from the surface and prevents the formation of gas bubbles, resulting in a more efficient and smoother polishing. This method is suitable for large or flat special steel components requiring a high-quality surface finish. In conclusion, the choice of the appropriate method for surface electropolishing of special steel depends on specific component requirements, such as size, geometry, and desired surface finish. Each method has its advantages and considerations, and seeking guidance from an experienced electropolishing specialist is advisable to determine the most suitable approach.

- Q: What are the different coating techniques for special steel?

- There are several coating techniques commonly used for special steel, including electroplating, galvanizing, powder coating, thermal spraying, and chemical vapor deposition. Each technique offers unique advantages and is chosen based on the specific requirements of the steel, such as desired appearance, corrosion resistance, hardness, or wear resistance.

- Q: What industries rely on special steel?

- The exceptional properties and outstanding performance of special steel make it indispensable in several industries. The automotive sector, for instance, heavily relies on special steel for the manufacturing of engine components, suspension systems, gears, and various other parts. Similarly, the aerospace industry extensively utilizes special steel due to its ability to withstand high temperatures, extreme pressure, and provide exceptional corrosion resistance. In the construction industry, special steel plays a crucial role in the production of high-rise buildings, bridges, and infrastructure projects, where strength, durability, and resistance to environmental factors are of utmost importance. The energy sector, including oil and gas, heavily depends on special steel for the production of pipelines, drilling equipment, and storage tanks, as it possesses remarkable mechanical properties and can endure harsh operating conditions. Additionally, special steel is widely used in manufacturing, machinery, defense, and tooling industries for various applications such as molds, cutting tools, and machine components. In summary, special steel is extensively utilized in industries that prioritize superior performance, durability, and reliability in their products and equipment.

- Q: Can special steel be used in the aerospace parts manufacturing industry?

- Yes, special steel can be used in the aerospace parts manufacturing industry. Special steel alloys are often chosen for their superior strength, corrosion resistance, and high-temperature performance, making them ideal for aerospace applications where durability and reliability are crucial.

- Q: What are the main challenges in machining special steel?

- The main challenges in machining special steel include its high hardness and low machinability, which make it difficult to cut and shape. Special steels also have a tendency to work harden, causing tools to wear out quickly. Additionally, special steels often contain alloying elements that can lead to heat build-up during machining, requiring careful selection of cutting parameters and cooling methods.

Send your message to us

CNBM Stainless Steel Deformed Bars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords