High Quality Deformed Steel Bar For Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

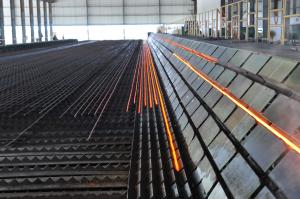

OKorder is offering High Quality Deformed Steel Bar For Construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Deformed Steel Bar For Construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's High Quality Deformed Steel Bar For Construction are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: HRB335

Size: 6mm-25mm

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | B | |||

HRB335 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%) | ||||||

≥335 | ≥490 | ≥16 | ||||||

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%) | ||||||

≥400 | ≥570 | ≥14 | ||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: what is the difference between actual weight and theoretical weight?

A3: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

.

Images:

- Q: How are steel rebars stored to prevent damage?

- To prevent damage, steel rebars are commonly stored in various ways. Firstly, they are typically kept in a clean and dry area that is protected from the elements. This safeguards against rust and corrosion, which can weaken the rebars over time. Moreover, rebars are often stored elevated off the ground, either on pallets or racks, to avoid contact with moisture and dirt. This not only makes them more accessible and easier to inspect but also eliminates the risk of damage. Additionally, bundling the rebars together and securely tying them with wire or bands ensures that they remain in place during storage and transportation. This prevents any unintentional movement or shifting that could potentially cause harm. Sometimes, a protective layer such as epoxy or plastic is applied to the rebars to create an extra barrier against moisture and other corrosive elements. Lastly, it is crucial to handle and transport rebars with caution to avoid accidental damage. Appropriate equipment, like cranes or forklifts, should be used to lift and move them, and workers should be trained in proper handling techniques to minimize the risk of bending, twisting, or other physical harm. Overall, storing steel rebars in a clean, dry area, elevated off the ground, securely bundled, and handled with care significantly reduces the risk of damage, ensuring that the rebars remain in optimal condition for their intended use in construction projects.

- Q: What are the guidelines for spacing and positioning steel rebars in concrete structures?

- The guidelines for spacing and positioning steel rebars in concrete structures are critical to ensure the structural integrity and durability of the construction. Here are some key guidelines to follow: 1. Rebar Spacing: The spacing between steel rebars in concrete structures is determined by the structural engineer or designer. It is typically expressed in terms of center-to-center spacing or clear distance between rebars. The spacing depends on the load requirements, concrete strength, and other factors specific to the project. The most common spacing ranges from 4 to 12 inches. 2. Cover Depth: The concrete cover depth refers to the distance between the outer surface of the concrete and the nearest surface of the rebar. It is essential to provide adequate cover to protect the rebars from environmental factors, such as corrosion and fire. The cover depth is typically specified in the project's design and can vary depending on the concrete's exposure conditions. 3. Rebar Positioning: The proper positioning of rebars is crucial to ensure they are placed in the designated locations within the concrete structure. The rebars should be securely supported and maintained in the correct alignment during the concrete pouring process. The positioning requirements may include specific lap lengths, overlaps, or hooking of rebars at junctions to ensure proper load transfer and structural continuity. 4. Chair Supports: Rebar chair supports are widely used to maintain the correct spacing and elevation of the rebars within the concrete structure. These supports are placed under the rebars at regular intervals to prevent sagging or displacement during concrete placement. The appropriate chair support type and height should be selected based on the project's requirements and the diameter of the rebars. 5. Tying and Binding: Proper tying and binding of rebars are essential to ensure they remain in position and maintain the required spacing during the concrete pouring process. Rebars should be tied securely using wire or rebar ties at appropriate intervals, typically every 12-18 inches. The ties should be tight enough to prevent movement but not overly tight to avoid damaging the rebars or causing concrete segregation. 6. Concrete Consolidation: During concrete placement, it is crucial to properly consolidate the concrete around the rebars to eliminate air voids and ensure adequate bonding between the concrete and the rebars. Vibrators or other consolidation techniques should be used to achieve proper compaction and ensure the rebars are thoroughly embedded in the concrete. Compliance with the guidelines for spacing and positioning steel rebars in concrete structures is essential to guarantee the structural strength, durability, and safety of the construction. It is crucial to consult and follow the project's design specifications and engage qualified professionals to ensure proper execution and adherence to these guidelines.

- Q: Can steel rebars be used in the construction of airports and terminals?

- Yes, steel rebars can be used in the construction of airports and terminals. Steel rebars are commonly used in reinforced concrete structures to provide strength and reinforce the concrete. In the construction of airports and terminals, where large spans and heavy loads are common, steel rebars are essential for ensuring the structural integrity and durability of the buildings. They help in withstanding the weight of aircraft, the constant movement of people and goods, and the overall demands of such high-traffic facilities.

- Q: Are there any alternative materials to steel rebars for reinforcement?

- Indeed, there exists a variety of alternative materials for reinforcement instead of steel rebars. One such material is FRP rebars, which consist of high-strength fibers like carbon, glass, or aramid embedded in a polymer matrix. These FRP rebars possess numerous advantages over steel rebars, such as a high strength-to-weight ratio, resistance to corrosion, and electromagnetic neutrality. They prove particularly valuable in situations where corrosion is a concern, such as marine environments or structures exposed to chemicals. Another alternative material is basalt rebars, which are formed by reinforcing basalt fiber with a polymer matrix. Similar to FRP rebars, basalt rebars offer advantages like a high strength-to-weight ratio and corrosion resistance. Additionally, they are non-conductive and non-magnetic, making them suitable for applications where electromagnetic neutrality is crucial, like in MRI facilities or near power lines. Besides FRP and basalt rebars, other alternative reinforcement materials include bamboo, timber, and composites made from natural fibers such as hemp or flax. These materials are commonly employed in sustainable construction practices or in regions where they are more easily accessible compared to traditional steel rebars. While they may not possess the same level of strength as steel, they can still provide adequate reinforcement for specific applications and offer other benefits like low environmental impact or ease of handling and installation. In conclusion, the availability of alternative materials to steel rebars provides engineers and architects with a range of options to select from based on their project's specific requirements, including factors such as strength, durability, cost, and sustainability.

- Q: What are the guidelines for repairing damaged steel rebars in a structure?

- When it comes to repairing damaged steel rebars in a structure, there are several guidelines that need to be followed to ensure the structural integrity of the building. Here are some key guidelines: 1. Inspection: Before starting the repair process, a thorough inspection of the damaged rebars should be conducted. This includes assessing the extent of the damage, identifying the cause of the damage, and determining whether repair is feasible or if replacement is required. 2. Cleaning: The damaged rebars need to be cleaned properly to remove any loose rust, scale, or other contaminants. This can be done using wire brushes, sandblasting, or other appropriate cleaning methods. 3. Removal of damaged material: Any corroded or severely damaged portions of the rebars should be removed. This may involve cutting out the damaged area and replacing it with a new rebar, or using techniques such as welding or epoxy bonding to repair the damaged section. 4. Surface preparation: The surface of the rebars should be prepared to ensure proper adhesion of the repair material. This may involve roughening the surface, applying a bonding agent, or using other surface preparation techniques depending on the specific repair method being employed. 5. Repair material selection: The choice of repair material will depend on factors such as the severity of the damage, the load-bearing capacity required, and the environment in which the rebars are located. Common repair materials include epoxy resins, cementitious mortars, or other specialized repair products. 6. Repair technique: The repair technique chosen should be appropriate for the specific damage and should comply with relevant industry standards and codes. Techniques such as welding, epoxy bonding, or mechanical splicing can be used to repair damaged rebars. 7. Quality control: Throughout the repair process, quality control measures should be implemented to ensure the effectiveness and durability of the repair. This may involve testing the repaired rebars for strength, monitoring the curing process, and conducting inspections to verify that the repairs have been carried out in accordance with the guidelines. 8. Documentation: It is essential to maintain thorough documentation of the repair process, including photographs, test results, and any relevant certifications or warranties. This documentation can be useful for future reference, maintenance, and to provide evidence of the repair work done. It is important to note that the guidelines for repairing damaged steel rebars may vary depending on the specific requirements of each project, local building codes, and the recommendations of structural engineers or repair specialists. Therefore, it is crucial to consult with experts in the field to ensure that the repair work is carried out safely and effectively.

- Q: Can steel rebars be used in architectural detailing?

- Yes, steel rebars can be used in architectural detailing. Steel rebars are often used to reinforce concrete structures and provide additional strength and stability. In architectural detailing, rebars can be incorporated into the design to enhance the structural integrity of the building or to create unique and intricate patterns. Rebars can be bent, shaped, and placed in various configurations to achieve the desired architectural effect. Additionally, steel rebars are durable, resistant to corrosion, and readily available, making them a popular choice in architectural detailing.

- Q: What are the guidelines for cutting and bending steel rebars on-site?

- The guidelines for cutting and bending steel rebars on-site typically include using appropriate tools such as a rebar cutter and bender, ensuring safety measures such as wearing protective gear, following the required dimensions and angles specified in the construction plans, and using proper techniques to achieve clean and accurate cuts and bends. It is crucial to follow local building codes, manufacturer's instructions, and industry best practices to ensure structural integrity and worker safety.

- Q: What are the factors to consider while designing with steel rebars?

- There are several factors to consider when designing with steel rebars, which play a crucial role in ensuring the structural integrity and performance of a construction project. 1. Load capacity: One of the primary factors to consider is the anticipated load capacity of the structure. Steel rebars are designed to provide reinforcement and enhance the tensile strength of concrete. Therefore, the size, spacing, and placement of rebars should be determined based on the expected loads that the structure will be subjected to. 2. Structural requirements: Different structural elements may have specific design requirements. For instance, beams, columns, slabs, and foundations have unique load distribution patterns, and the design of rebars should be tailored to meet these specific needs. The dimensions, quantity, and arrangement of rebars will vary based on the intended structural purpose. 3. Durability: Steel rebars are exposed to various environmental conditions, such as moisture, temperature fluctuations, and chemical exposure. These factors can lead to corrosion, which can significantly impact the strength and longevity of the structure. Therefore, designers need to consider the required level of durability and specify appropriate protective measures, such as using epoxy-coated rebars or providing sufficient concrete cover. 4. Construction methodology: The construction method used for the project can influence the design of steel rebars. Factors such as formwork, construction joints, and accessibility during the placement of rebars need to be taken into account. The design should accommodate the construction process, ensuring ease of installation and proper alignment of rebars. 5. Building codes and regulations: Compliance with local building codes and regulations is crucial to ensure the safety and legality of the structure. Designers must consider the specific requirements outlined in the codes, including minimum rebar sizes, spacing, and cover requirements. Adhering to these standards ensures that the structure meets the necessary safety standards and can withstand potential hazards. 6. Cost-effectiveness: While ensuring structural integrity, it is also essential to consider the cost-effectiveness of the design. Optimizing the placement and arrangement of rebars can help minimize material and labor costs without compromising the safety and performance of the structure. In conclusion, designing with steel rebars involves considering factors such as load capacity, structural requirements, durability, construction methodology, building codes, and cost-effectiveness. By carefully evaluating these factors, designers can create robust, safe, and long-lasting structures.

- Q: How do steel rebars affect the overall constructability of concrete structures?

- Steel rebars have a significant impact on the overall constructability of concrete structures. Rebars, also known as reinforcing bars, are embedded within the concrete to provide strength and enhance its structural integrity. These steel bars play a crucial role in resisting tensile forces that concrete alone cannot withstand. One of the primary ways rebars affect constructability is by increasing the load-bearing capacity of concrete structures. By reinforcing the concrete, rebars help distribute the applied loads more evenly, reducing the risk of structural failure or collapse. This allows for the construction of taller, larger, and more complex concrete structures that can safely accommodate heavier loads. Moreover, rebars also improve the durability and longevity of concrete structures. Concrete is strong in compression but weak in tension, making it susceptible to cracking and failure under tensile stress. The presence of steel rebars helps to counter this weakness by absorbing and distributing the tensile forces, preventing or minimizing cracks and enhancing the overall durability of the structure. In terms of constructability, the use of rebars simplifies the construction process by allowing for efficient and precise placement of concrete. Rebar cages are typically assembled prior to pouring the concrete, acting as frameworks that provide support and reinforcement. This enables faster and more accurate construction, reducing the risk of errors and rework. Furthermore, rebars also enhance the constructability of concrete structures by enabling flexibility in design. The ability to strategically position and shape rebars allows engineers to create complex structural elements, such as beams, columns, and slabs, with specific load-bearing capabilities. This versatility in design promotes architectural creativity while ensuring the structural integrity of the construction. However, it is important to note that the improper placement or inadequate amount of rebars can have detrimental effects on the constructability and overall performance of concrete structures. Insufficient reinforcement can lead to structural weaknesses, increased vulnerability to seismic activity, and reduced resistance to environmental factors like corrosion. Therefore, proper design and installation of rebars, in accordance with structural engineering standards and codes, are crucial to ensure the optimal constructability and long-term functionality of concrete structures.

- Q: How are steel rebars connected or joined together during construction?

- Steel rebars are typically connected or joined together during construction by overlapping the ends of the rebars and tying them using steel wire or using mechanical couplers.

Send your message to us

High Quality Deformed Steel Bar For Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords