CNBM Seamless Steel Pipe Hot selling With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DETAILS

1.Structure of Seamless Steel Pipe Description:

A large amount of Seamless Steel Pipes is offered to the clients at cost effective rates. These pipes are extremely durable, resistant to corrosion and have high tensile strength. Our pipes are used in nuclear plants, power plants, refineries and construction industry across the country. Furthermore, we are capable of providing these seamless pipes to the clients in bulk quantity.

2.Main Features of the Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3.Packaging & Delivery:

| Packaging Details: | Seaworthy packages, bundles wrapped with strong steel strip |

| Delivery Detail: | 15-30 days after received 30% TT |

4.Seamless Steel Pipe Specification:

| Standard: | GB, DIN, ASTM,ASME, ASTM A106-2006, ASTM A53-2007 |

| Grade: | 10#,20#, 45#, 16Mn |

Thickness: | 8 - 33 mm |

| Section Shape: | Round |

| Outer Diameter: | 133 - 219 mm |

| Place of Origin: | Shandong, China (Mainland) |

| Secondary Or Not: | Non-secondary |

| Application: | Hydraulic Pipe |

| Technique: | Cold Drawn |

| Certification: | API |

| Surface Treatment: | factory state or painted black |

| Special Pipe: | API Pipe |

| Alloy Or Not: | Non-alloy |

| Length: | 5-12M |

| Outer Diameter: | 21.3-610mm |

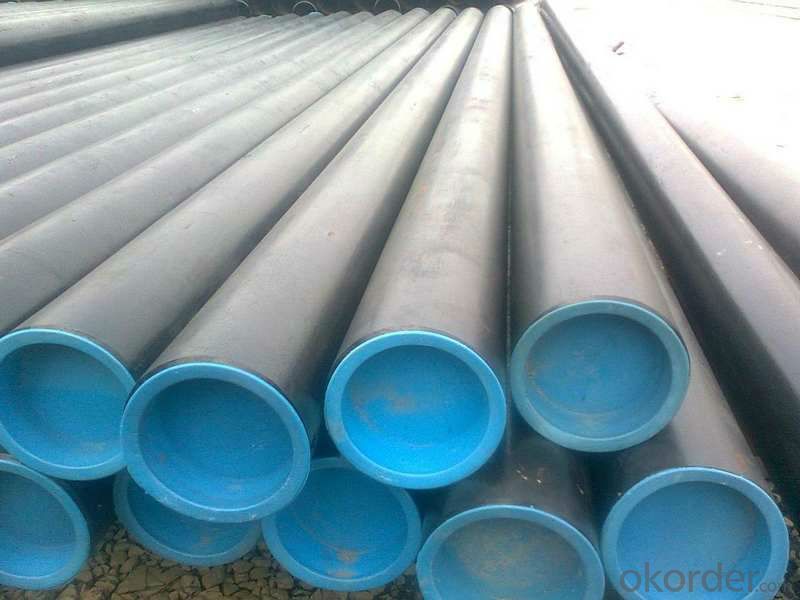

5.Product pictures

6.FAQ of Seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: Can steel pipes be used for stadium construction?

- Yes, steel pipes can be used for stadium construction. Steel pipes offer several advantages that make them suitable for this purpose. Firstly, steel pipes are strong and durable, making them capable of withstanding heavy loads and providing structural stability to large structures like stadiums. They have high tensile strength, which means they can resist bending or breaking under pressure. Additionally, steel pipes are resistant to corrosion, which is crucial for outdoor structures like stadiums that are exposed to various weather conditions. Their resistance to rust and other forms of degradation ensures the longevity of the stadium. Furthermore, steel pipes are versatile and can be easily fabricated into different shapes and sizes, allowing for customized designs and efficient installation. Moreover, steel pipes offer cost-effectiveness in stadium construction. They can be easily produced in large quantities, making them readily available and affordable. The ease of transportation and installation of steel pipes also contributes to their cost-effectiveness. Another advantage of using steel pipes for stadium construction is their sustainability. Steel is a recyclable material, and using steel pipes promotes environmental responsibility. The recyclability of steel reduces the demand for new materials and minimizes waste. In summary, steel pipes can indeed be used for stadium construction due to their strength, durability, resistance to corrosion, versatility, cost-effectiveness, and sustainability.

- Q: What is the role of steel pipes in the construction of stadiums?

- Steel pipes play a crucial role in the construction of stadiums as they are used for various purposes such as structural support, framing, and the creation of plumbing and drainage systems. These pipes provide the necessary strength and durability required to withstand heavy loads, ensuring the overall stability and safety of the stadium structure. Additionally, steel pipes are also used for the installation of HVAC systems, electrical wiring, and other infrastructure components, making them an essential element in the construction process.

- Q: How do steel pipes compare to other materials, such as PVC or copper?

- Steel pipes are generally more durable and have a higher resistance to heat, pressure, and corrosion compared to PVC or copper pipes. They are commonly used for applications that require strength and longevity, such as in industrial settings or for transporting high-pressure fluids. However, steel pipes can be more expensive and heavier than PVC or copper, making them less suitable for certain residential or lightweight applications. Ultimately, the choice of material depends on the specific requirements and budget of the project.

- Q: How to calculate the maximum bending stress of steel pipe? Is there a list of the maximum flexural normal stresses for steel pipes of different materials and diameters?

- Wnx - net sectional modulus of steel tubes, also called net sectional resistance moment. If the section is not weakened, it can be found in the steel sheet of the steel structure design manual. If the section is weakened, it can be calculated by the formula according to the sectional dimension according to the formula of the material mechanics.

- Q: How much is the tube?

- The theoretical weight calculation formula of ordinary carbon steel tube is:The weight of each meter is kg/m= (outer diameter mm-, wall thickness mm) * wall thickness mm*0.02466For example: inventory 20# pipe diameter of 108*4.5 weight per meter:Kg/m= (108-4.5) *4.5*0.02466=11.485In accordance with the diameter of 108*4.5 steel pipe market price is 4500 yuan / ton as an example, we can know the diameter of 108*4.5 steel pipe per meter price: 11.485*4.5=51.68 yuan.

- Q: Can steel pipes be used for transporting hazardous materials?

- Yes, steel pipes can be used for transporting hazardous materials. Steel is known for its strength and durability, making it suitable for handling and containing hazardous substances. It is commonly used in various industries, such as oil and gas, chemical, and wastewater treatment, to transport materials that pose a potential risk to human health or the environment. Additionally, steel pipes can resist corrosion and high pressure, ensuring the safe transportation of hazardous materials.

- Q: What are the different types of steel pipe connections for steam pipelines?

- There are several types of steel pipe connections commonly used for steam pipelines, including threaded connections, flanged connections, welded connections, and grooved connections. Each type has its own advantages and is selected based on factors such as the pipe size, pressure rating, and ease of installation and maintenance.

- Q: How are steel pipes used in the construction of tunnels?

- Steel pipes are used in the construction of tunnels for various purposes such as drainage, ventilation, and transportation of utilities. They provide structural support, ensuring stability and strength, while also allowing for the efficient flow of water, air, and other essential resources within the tunnel.

- Q: How do steel pipes handle seismic activities?

- Steel pipes are highly durable and resistant to seismic activities. Their strong and flexible nature allows them to withstand the ground shaking during earthquakes without compromising their structural integrity. Steel pipes are designed to absorb and distribute the energy generated by seismic waves, minimizing the potential damage caused by earthquakes. Additionally, their high strength-to-weight ratio makes them ideal for withstanding the lateral forces and ground movements associated with seismic activities.

- Q: Is the steel frame on each floor supporting formwork (floor) called full scaffolding?

- The scaffold is also called full house scaffolding is a construction process for building a scaffold. Hall scaffolding relative to other scaffolding system density, that is, the house full of shelves. The full scaffolding is more secure than the rest of the scaffolding.

Send your message to us

CNBM Seamless Steel Pipe Hot selling With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords