CMAX PVC、PVG Conveyer Belt Cover Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

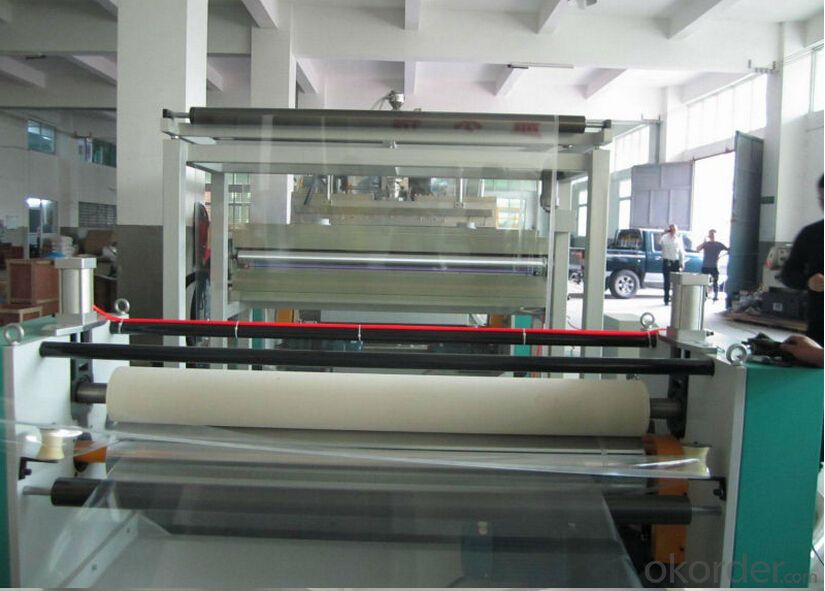

Good Quality PEVA Car Cover Film Extruder uses LDPE, PP, EVA, PEVA, LLDPE, HDPE, TPU as raw material, and then laminates the extruded film onto various kinds of substrates, such as nonwoven fabric, BOPP, BOPET, BOPA, and paper etc. The final products are widely used for hygienic and medical products, the packaging of food, chemical industry, electrical products and metallurgy etc.

Packaging & Delivery

| Packaging Detail: | Best Sea transportion package to avoid damagement |

| Delivery Detail: | 60 days |

In order to the customer’s technics requirement for the conveter belt,CNBM successfully develops serials conveyer belt cover extruder and relation mould,it can be molding for the pvc belt’s surface,adjust the thickness of the cover,leave out the others.This extruder install on the left and right,have good plastic,high output,low power and the high design for the produce

Technical parameters

| Model | Screw Diameter | Screw L/D ratio | T Die Width | Film Width | Film Thickness | Liner Speed |

CMAX-LY-1250 | 90mm | 36:1 | 1250mm | 1000mm | 0.02-0.3mm | 30-80m/min |

CMAX-LY-1900 | 110mm | 36:1 | 1900mm | 1600mm | 0.02-0.3mm | 30-80m/min |

CMAX-LY-2300 | 120mm | 36:1 | 2300mm | 2000mm | 0.02-0.3mm | 30-80m/min |

CMAX-LY-2600 | 135mm | 36:1 | 2600mm | 2300mm | 0.02-0.3mm | 30-80m/min |

Applications:

1) Hygieneproducts: sanitary napkin, lady pad, baby diaper, medical surgical gown, pet cushion, disposable underpad and etc.

2) Daily necessities: raincoat, umbrella, tablecloth, western style suit cover, glove, apron, bath curtain, bath hat and etc.

3) Packaging: computer cover, electric appliance cover, shoes cover, cosmetic soft package, shopping bag, gift bag, document folder, file cover and etc.

Product show:

FAQ:

1. What are CNBM coming from?

CNBM made the first Chinese screw and barrel in 1978 in brand. Nowaday, in this location BEIJING city, there are more than thousands of companies. After more than 35 years development, CNBM is the TOP 1 extrusion machine supplier in China

2. Why should I choose CNBM?

We follow Germany type of business heading as the worldwide reliable supplier of plastic extrusion line. We have already provided more than 500 lines located in all countries because we are providing the lastest technology, qualified machine, reliable component and best after-service. 300 Engineers are travelling in the world throughout year for installation and test of machine, the after-service are free and availble forever. That's why we grow up from 10 staff company to 3000 staff Pioneer of Chinese extrusion machine supplier.

- Q: Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q: What is the adjustment method of China's extrusion machine die?

- The adjusting method of the die is as follows: (data refer to China. Extruder)(1) air to mold: adjust the die before production, adjust the distance between the mold core and the die suite evenly with the naked eye, and then screw the die screws.

- Q: Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Pay attention to the ground anchor.It is better to fasten the joint of the equipment itself.Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q: Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: Comparison of injection molding machines and Extruders

- The plastic to replace steel or nonferrous metal, plastic cement, which is widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, household appliances, petrochemical and defense, extruder and daily life other fields. So it can be predicted that in twenty-first Century, the plastic will be one of the most important raw material of human activities. The extruder design due to extrusion molding is the main form of plastic processing, so the development of plastic extrusion molding technology and equipment has important significance. The polymer materials used in blending type mixing equipment modification there are three main types: parallelwith twin-screw extruder, reciprocating screw kneader and series disc extruder. The small corotating twin screw extruder has domestic production can squeeze But tons of large mixing extrusion granulation unit will rely on the import machine technology. At the same time. Reciprocating screw kneader and series disc extruder is a necessary device for preparing high fill and high added value of polymer alloy, the current domestic research on them is just in the prototype stage, specifications, varieties not all, have broad prospects for development.

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- 1. injection molding2., the structure is relatively complex, high appearance requirements. Extrusion does not meet requirements3. most are: ABS, ABS+PC, PP and so on4., according to color requirements granulation - drying particles - filling the mold ---- debugging injection molding machine ---- injection molding production - after the selection of finished packaging (if silk screen requirements, but also the need for silk screen)

- Q: There is a 90 extrusion machine, used in the production of communication cables (outside the cable core is extruded with a layer of LLDPE), now is the configuration of Y2-280M-490KW167A inverter type ACS510197A + ABB), General Motors now found low speed when the current is too large, what reason? How to solve? The details are as follows: used for communication cable production HYA30*2*0.4, 1, line speed is 50 m / min, inverter display frequency 35.3HZ current: 116A; 2, line speed is 40 m / min, inverter display frequency of 28.2hz, current: 140A3, line speed is 35 m / min, the frequency converter significantly method: 157A 24.6HZ frequency current, because the product variety and technical reasons, we need to be in the frequency of 10HZ production. Now, it seems that if I reduce the speed again, the current will probably exceed the rated current. What should I do? Is the motor changed to frequency conversion motor? Or inverter? How to solve? Please heroes pointing, thank you!

- Yes, the load characteristics and control characteristics are also to be matched. Otherwise, it will be very inappropriate and lead to abnormal phenomena.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

Send your message to us

CMAX PVC、PVG Conveyer Belt Cover Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches