CMAX High Output Fully Automatic Blow-molding Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

worked in this field for more than 5 years

Life span more than 15 years

world first class spare parts,lowest failure rate

Fully Automatic Blow-molding Machine

A:Brief Introduction

It can blow bottles in shapes for different use: medicine, food, pesticide, cosmetics, house-hold products, and other packing containers.

1).High Automatization:Automatic malfunction alarm systems, automatic protection from cold and periodic record of output.

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quality:Highly precise blow-mould closing system ensure quality.

4). Double proportional hydraulic system

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

B.Settings:

a).PLC colour display: LS(KOREA)

b).Pneumatic parts:YUKEN(JAPAN)

c).Controller of temperature:FUJI(JAPAN)

d).Other electric parts are all world-famous brand

C.Machine Features:

C.1. Stable performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself.

C.4. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. Highly-efficient plasticizing mixing screw guarantees fully and evenly plasticization; elements of the mold head adopt good quality steel with precise finishing and heat treating.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.1 percent.

C16. Variable-frequency speed regulation, reduction gearbox, enjoying steady speed regulation, low noise and durability

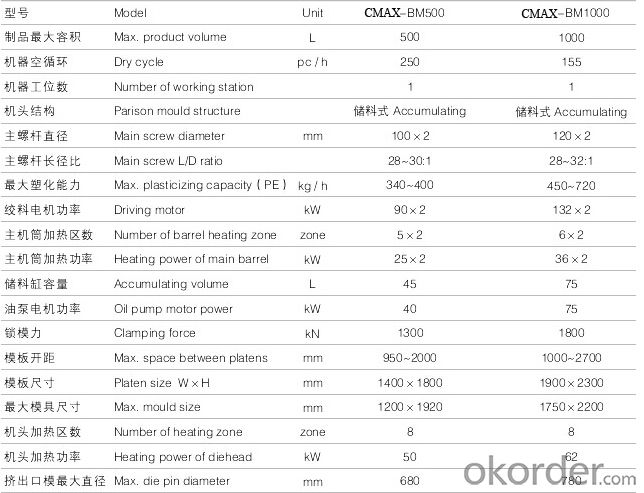

D.Technical Parameter:

A:Brief Introduction

It can blow bottles in shapes for different use: medicine, food, pesticide, cosmetics, house-hold products, and other packing containers.

1).High Automatization:Automatic malfunction alarm systems, automatic protection from cold and periodic record of output.

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quality:Highly precise blow-mould closing system ensure quality.

4). Double proportional hydraulic system

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

B.Settings:

a).PLC colour display: LS(KOREA)

b).Pneumatic parts:YUKEN(JAPAN)

c).Controller of temperature:FUJI(JAPAN)

d).Other electric parts are all world-famous brand

C.Machine Features:

C.1. Stable performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself.

C.4. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. Highly-efficient plasticizing mixing screw guarantees fully and evenly plasticization; elements of the mold head adopt good quality steel with precise finishing and heat treating.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.1 percent.

C16. Variable-frequency speed regulation, reduction gearbox, enjoying steady speed regulation, low noise and durability

D.Technical Parameter:

Company Information

CNBM International Corporation

(CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.With the advantages in Cement, Composite Materials, New Building Materials and Engineering, We are enlarging sub-brand. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. In line with the business, CNBM International launched E-business platform Okorder.com. It conformed the best resource and logistics to meet the customers’ request with 24 hours full-time service.

Our Vision: Initiate new global trading structure; create new value for benefit related partners.

We will do utmost to promote rational use of resources under the new structure, meanwhile, create new value of “green, environment friendly and sustainable’ for a more prosperous future.

CNBM International Co. Carpet Dept.

At CNBM International Co. Carpet Dept., we design and weave beautiful carpets of superb durability - with axminster, tufted and wilton carpets to suit all hospitality environments. · There is no size limitation on rug size. Rugs can be created with a variety of materials from pure wool to woolen silk, from natural fiber to chemical fiber.

- Q: What is the difference between the high efficiency vacuum oil filter and the two-stage vacuum oil filter in transformer oil filter?

- The dry degree, the breakdown voltage of the oil value, disposable filtering effect are greatly improved, shorten the processing time of oil, so as to improve the performance of transformer oil, and vacuum, can use at high altitudes also.

- Q: Where is the vacuum oil purifier repaired?

- Then there is a problem with the pump, the pump needs to be repaired.Find a supplier to repair it

- Q: Points for attention of vacuum oil filter

- 1.4 check whether the external power supply is correct, whether the power cable meets the capacity requirements of the oil filter.1.5 check the machine housing should be reliable grounding.1.6 check that all rotating parts should be free of obstruction.1.7 test turn, check the oil pump, vacuum pump and other motor steering should meet the requirements.1.8 check whether the cooling water connection is reliable and the water should be clear.1.9 check field fire extinguishers to meet the requirements.

- Q: I change the oil machine! I recently changed my false engine oil! It ran 2000 kilometers! Can you change the oil filter instead of the engine oil?

- Hello, replace the oil, you must replace the filter, filter oil filter impurities, or you change the new oil, filter impurities will cycle up, the new oil on the white change.

- Q: What is the optimum oil temperature of vacuum oil filter?

- 1. open the valve on the intake pipe of the vacuum pump 29, start the vacuum pump 31, and pay attention to the rising of the vacuum.2. the relief valve will be opened, the pressure adjustment at 0.3Mpa (factory has been adjusted).

- Q: What's the difference between an oil filter and an oil press?

- The main function of the oil filter is to filter the impurities in the oil and remove moisture, the higher point can also adjust the pH of the oil, etc., and the oil press usually refers to the extraction of oil from the plant through physical processes.

- Q: Hydraulic press to buy automatic integration of good or alone to buy the right?

- The split oil filter is an enlarged oil filter, in contrast to an integral oil filter, the split oil filter is faster.In addition, different oil filters are arranged for different press processes and press methods, not only vacuum oil filters.Therefore, stand-alone configuration is better than one configuration.

- Q: Can vacuum turbine oil filters be used to filter transformer oils?

- And the purification treatment of vacuum oil turbine oil machine is generally a single stage vacuum treatment, vacuum oil purification of transformer oil is the general requirements for vacuum ZYAXD double stage vacuum oil filter (below 110KV units and small transformer can use ZY single stage vacuum oil filter). This is because the requirement of improving the withstand voltage of transformer oil, vacuum oil filter ordinary machine, vacuum is not enough, not deep water filtration, with current technology only adopts double stage vacuum oil filter to enhance vacuum, vacuum flash ability to increase transformer oil content decreased to 30ppm and below.4. summary: if the requirements are not the same, the theory can be dealt with, but is generally not recommended, two kinds of oil additives are not the same, with a general oil filter is easy to cause the oil mixed pollution, and the use of different occasions, the requirements are not the same, TYAXD turbine oil filter oil machine processing of transformer oil is likely to reach the technical requirements, so in order to facilitate and ensure the filtering effect, oil filter is the best to buy a special filter and transformer oil, thus reducing the cost of the use of

- Q: Filter turbine oil filter, filter Q oil?

- In the non stress, very casual circumstances, you can filter, but if the two kinds of oil to be strictly distinguished, it is recommended that you do not mix, but also in the technical requirements are not the same

- Q: How to solve the problem of oil leakage in the centrifugal oil filter?

- Resolvent:1. open the case and reinstall the lower filter2. carefully sift and remove impurities before importing the oil3. change the oil filter line4. clean filter screen impurities.

Send your message to us

CMAX High Output Fully Automatic Blow-molding Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords