CMAX High Output Rubber Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Wooden crate |

| Delivery Detail: | 15 days when we received your PO |

Automatic Plastic Filament Wire Making Extruding Binding Machine

1. Easy to operate

2. Producing plastic filaments of diameter 1.2mm-8.0mm

3. Fit various standard moulds,easy to change

4. Producing speed up to 40kgs per hour

Features

1. Adjustment of extruding and winding speed for adjustment of wire diameter;

2. Sound roundness of extruded wire and stable wire diameter to promote forming production rate and ensure quality of plastic spiral;

3. Non-trained operators can grasp the skill in a short period.

4. For a variety of materials, like PET, PVC,

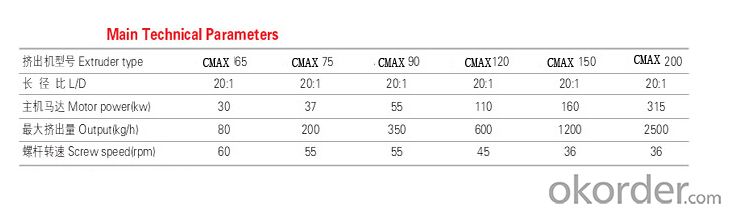

Technical Parameters

If you need a binding machine for your office or work space, you have come to the right place. MyBinding.com is your premier source for binding systems and supplies. In fact, we carry more binding machines and book binding systems than any other company on the Internet. No one knows more about these products than we do. We carry systems for traditional plastic comb, wire-o, and spiral coil binding as well as the Velobind and ProClick systems. If you're new to the market, try some of our excellent learning resources. The video to your right is a great place to start. In addition, we've featured helpful machine descriptions below. And, as always, please call, email, or chat if you have any questions!

- Q: For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- Depending on your specific specifications, if XLPE is insulated, extrusion die with small touch line, set on the use of cable diameter, large core conductor than a few tenths of good, if you like to use 70 square tube extruding mold insulation of the conductor element some is big 1 can be set according to the touch, the tensile ratio calculation, PVC1.6 DYWL material with smaller good-looking it is simple of the extrusion process

- Q: Basic parameters of extruder screw

- 3, compression ratio epsilon, also known as the geometric compression ratio of screw, is the ratio of the volume of the first screw groove to the volume of the last screw groove at the homogenization section. It is determined by the physical compression ratio of plastics - that is, the density of the product and the density of the performance of the feed. The extruder is relatively compressed, the purpose is to make granular plastics fully plasticized and compacted. The selection of compression ratio should be different when different kinds of processing plastics are used. According to the compression ratio, the types of screw can be divided into three types: equidistant, unequal depth, equal depth, unequal distance, unequal depth, unequal distance. Among them, equidistant and unequal depth is the most common one. This kind of screw is easy to process, the contact area of plastic and cylinder is large, and the effect of heat transfer is good.

- Q: What is an extruder?

- This method of forming is continuous molding, such as pipes, plastic profiles, films and so onThe machine also has a single screw, twin-screw, multi screw points.The forming methods are single extrusion and coextrusion only.

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Cable extruder type 657090 machine, describes the diameter of the screw, the unit is mm.The greater the number, the greater the equipment, the greater the amount of gumIt is usually marked on the control cabinet of the equipment

- Q: Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: How to adjust the 65 screw gap in the extruder?

- This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

Send your message to us

CMAX High Output Rubber Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches