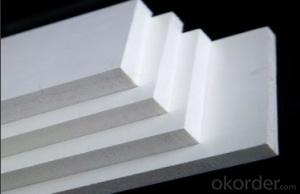

PVC Free Foam Board, Skinning Foam Board Production Lines/wpc skinning foam sheet mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.SJSZ 80/156 Conical twin Screw Extruder

ABB frequency converter, SIEMENS contactor, OMRON Japan, Motor power:75KW

2.Calibration unit

calibration plate:1500mm×500mm 4couples

3. Cooling tank and bracket

length:6000mm

trimming knife:3 sets

4. Haul-off unit

8 couples

cylinder clamping and loosening

5. Cutting unit

6. Stacker

7. Mould (T-Die )

1.Excellent Features:

Strong and durable; Lightweight and easy to install; Not easy to scratch;

Will not rot, warp, delaminate, cup or twist;

Resistant to weather, shock and abrasion;

Salt water corrosion resistant;

Impervious to salts, insects and many chemicals, including some acids;

Doesn't mold; Can be worked just like wood;

Non-toxic; 100% recyclable; Fire-retardant (self-extinguishing);

Easy to clean; Virtually maintenance free;

Screw

Material 38CrMoAl superior alloy steel nitriding treatment

Screw dia. Φ51/105mm

Quantity 2 pieces

Gearing type conical gearing

Rotary speed 1-30r/min

Rotary direction reverse direction outside

Depth of nitration 0.4-0.6mm

Hardness of nitriding HV740-940

Roughness of surface 0.8µm

Barrel

Material 38CrMoAl superior alloy steel nitriding treatment

Depth of nitration 0.5-0.7mm

Hardness of nitriding HV940-1100

Roughness of surface 0.8µm

Heating method cast aluminium heater

Heating zones 4 zones

Heating power 8KW

Cooling method by fan

Cooling power 3×250W

Transmission deceleration system

Main extruder driving motor 15KW

Motor type AC motor

Motor speed adjusting type by transducer

Distribution gear box type rigid tooth surface gear grinding and bevel wheel combine

Fix quantity material supplying system

Material supplying method by screw

Screw rotary speed 0-45r/min

Motor power 0.75KW

Speed adjust method by transducer

Exhaust system

Vacuum pump type water cycle vacuum pump

Motor power 1.5KW

Vacuum degree 0-0.075MPa

Our Services

1.We can make and manufacture products according to customer specific needs.

2.Provide best and professional service for you, please contact with us freely.

3.For more information, please contact us at any time.

4.Stable performance, best price, good quality , good after-sales service.

- Q: What is an extruder?

- This method of forming is continuous molding, such as pipes, plastic profiles, films and so onThe machine also has a single screw, twin-screw, multi screw points.The forming methods are single extrusion and coextrusion only.

- Q: producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- This is often called information information, this website. Reference: Fox information Qilu Chemical City PE market by the petrochemical price driven price continues to rise, 7042 no tax 9350-9400 yuan / ton, 02TN26 no tax,

- Q: Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q: Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Pay attention to the ground anchor.It is better to fasten the joint of the equipment itself.

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: What should be paid attention to in the daily maintenance of the extruder?

- Attachment(1) inspect the rolling barrel, vibrating screen, motor and so on, and leak out the sealing parts.(2) cooling equipment and piping are clean and clean, and there is no suspended impurity in industrial soft water. Water filters and water tanks should be regularly checked, cleaned, kept clean and replaced with new water.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat, because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Plastic tensile testing without tension is strong that said, you should be the low tensile strength, tensile strength for 2 kinds of films, one is the transverse tensile strength, a longitudinal tensile strength, is a reflection of the tensile properties, the tensile strength of the plastic bag if you low, because your choice of materials is not brittle material or toughness (PE/PP/PVC/PET/PBT/PC do not know or what material) if you insist on using this material, make plastic bags, you can modification method by crosslinking, adding additives, improving formula, to achieve the goal, the specific situation you need to find a degree in Polymer Science plastic engineer, they will tell you.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

Send your message to us

PVC Free Foam Board, Skinning Foam Board Production Lines/wpc skinning foam sheet mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords