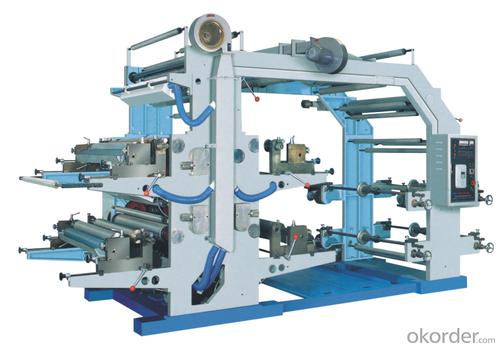

CMAX Full-Automatic Flexo Printing Machinery

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX LX308N Automatic Cardboard Box Machine

1.Product introduction:

This machine is suitable for printing such packing materials as polyethylene,polypropylene plastic bag,cellophane and roll paper,etc.And it is a kind of ideal printing equipment for producing paper packing bag for food ,supermarket handbag and clothes bag,etc.

2. The main features:

1. Take it easy, accurate color, long life.

2. Use motors, variable frequency speed control, saving electricity, small running fluctuations.

3. Off printing roll automatic stop the ink-running motor, and up-printing roll automatic start running the ink.

4. Use special synchronous belt drive, accurate printing size.

5. Two sets of heating devices, including central heating and constant temperature control system for group control.

6. Low-roller special steel processing, and special process, and plating thickness of 0.1mm protective layer of hard chromium.

7 Alloy roll with hard oxidation, treating by dynamic balance, static balanced.

8 With cold wind bellows, and can effectively prevent produce with ink adhesion after printing

9. Print produce are clear and good arrangement quality.

10. Bearing: NSK, Japan Brand, Germany ASNU aluminum alloy roll

3. Main parameter:

Specification | 13"(10330) | 16.5"(10420) | 20.5"(10520) | 25.5"(10650) |

Max web width | 340mm | 430mm | 530mm | 660mm |

Max printing width | 330mm | 420mm | 520mm | 650mm |

Max die-cutting width | 330mm | 420mm | 520mm | 650mm |

Printing repeat length | 190-650mm | 190-650mm | 190-650mm | 190-650mm |

die-cutting repeat length | 190-650mm | 190-650mm | 190-650mm | 190-650mm |

Max unwinding diameter | 1016mm | 1524mm/1016mm | 1524mm/1016mm | 1524mm/1016mm |

Max rewinding diameter | 1016mm/762mm | 1016mm/762mm | 1016mm/762mm | 1016mm/762mm |

Gearing | 1/8cp | 1/8cp | 1/8cp | 1/8cp |

Max printing speed | 150m/min | 150m/min | 150m/min | 150m/min |

Drying mode | hot air drying/IR drying/UV drying | |||

Applicable ink | · eco-friendly water-based ink/UV ink/solvent ink | |||

4. Detailed parameter:

4.1) Double unwind unit:

Max. unwind diameter | Φ800mm |

Unwind Way | Center unwind, with 10KG powder magnetic and auto tension control 2pcs |

Tension precision | ±0.3kg |

EPC System for unwind | 1pcs |

Unwind material holder | By air shaft , 2 pcs |

Unwind web cylinder | Φ76mm (inner diameter) |

4.2) Printing Unit:

Principle of Work | Belt Drive |

Suitable Printing Ink | Water-based ink or Oil-based ink |

Material of Plate | Resin or Rubber |

Constitution of Printing | Chrome plated roller, Rubber roller, Anilox roller, Plate cylinder |

Anilox roller | High speed machine:ceramic anilox roller (100-1000lpi), chamber doctor blade for 30-150m/min |

Printing Pressure | Mechanical adjust |

Color register type | By Manual |

Printing plate lifting system | Automatic Hydraulic cylinder control roll up and down |

4.3) Heating and Drying Unit:

Dryer | Electrical heat drying |

Blower | 4kw x 1pcs |

Double Blower way circle | Centralized heat, exhaust gas pumpback |

Power of Heating | 32 kw |

4.4) Double Rewind Unit:

Max. rewind diameter | Φ800mm |

Rewind Way | Centre rewind; |

Tension control system | Automatic tension control 2pcs |

Rewind material holder | By air shaft , 2pcs |

Rewind motor | 1.5Kw, Taiwan motor |

Rewind web cylinder | Φ76mm (inner diameter) |

5.Optional parts which extra cost buy:

NO. | Goods of Descriptions |

1 | Printing cylinder which use on flexographic printing machine |

2 | Corona treatment |

3 | Monitor system (also called image inspect device): screen+camera+controller |

4 | Pate mounting machine(easier to mount plate) |

5 | Plate making machine |

6 | Anilox roller cleaning machine ( especially client buy machine for paper printing) |

7 | Ink viscosity measurement ( 1 color need 1pcs) |

6.Product show:

7.FAQ:

1.Q: How about the after service?

A: We have a strong team, special for after service. We can arrange engineers to do service for you.

2.Q: Are you factory or trading company?

A: We are a factory in this field nearly 20 years.

3.Q: Where is your factory located? How can I visit there?

A:Our factory is located in Beijing City, China, near to the Beijing airport. You can fly to Beijing airport directly.

4.Q:How does your factory do regarding quality control?

A:Quality is priority. We always attach great importance to quality controlling from the beginning.

5.Q: why choose CNBM International Corporation?

A: We are one of leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.

Welcome to visit us and contact us for any problems!

- Q: What is a letterpress printing machine?

- The When the machine is working, the platform is reciprocating, the printing speed is limited, so the output is not high; round pressure round letterpress printing machine, also known as rotary printing press, it install plate version of the plate and embossing institutions are circular drum.

- Q: What is the basic classification of printing machinery?

- Fourth, in accordance with the printing format is divided into "eight open printing presses, four open printing press, off the printing press, full Zhang printing press, super full Zhang printing press;

- Q: What is the historical development of presses?

- The first stage was the heyday of the development of the offset printing process from the beginning of the 1980s to the early 1990s,

- Q: What is the application of the press?

- Printing machine at the start, the motor current will be 5-6 times higher than the rated,

- Q: What is flat pressure printing press?

- This type of press has a movable type machine, copper and zinc version of proofer and disc machine.

- Q: What is the development of printing machinery?

- to achieve The total profit of 1.265 billion yuan, the total profit growth rate of more than 100%; product sales profit of 2.887 billion yuan, an increase of 22.06%. In 2011, in the domestic macroeconomic environment for the better, the printing machinery industry continues to maintain a better development.

- Q: What is the direction of the printing press?

- Large, multi-color, multi-functional, and automation, linkage, serial models and models, also growing.

- Q: What is a screen printing machine?

- Production of wire mesh material in addition to silk, but also available nylon wire, copper wire, wire or stainless steel wire

- Q: What is a round pressure round press?

- At the time of printing, the impression cylinder is printed with a substrate, which is pressed in the opposite direction with respect to the plate cylinder.

- Q: What is gravure printing machine?

- The main feature of gravure printing presses is that the graphic part of the printing plate is concave and the blank part is raised, which is opposite to the layout of the letterpress printing press.

Send your message to us

CMAX Full-Automatic Flexo Printing Machinery

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches