CMAX Large Diameter HDPE Water Supply and Gas Supply Plastic Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery:

| Packaging Detail: | Export packing, covered with film for dustproof, wooden crates packing for sea transport |

| Delivery Detail: | 50 days after receiving 30% advanced payment |

Water Supply And Gas Supply HDPE Large Diameter Pipe Production Line

Welcome to visit our Water Supply And Gas Supply HDPE Large Diameter Pipe Production Line!

Application:With this production line you can extrude high quality large diameter water supply and gas supply pipes.

The pipes produced by our line have excellent stiffness and flexibility, resistance to creep deformation,excellent heat-linkage. Large diameter HDPE pipes start to play very important role in the city water and gas supply systems.

Properties and Advantages: The production line consists of control system, extruder,mould, calibration unit, haul-off unit,planetary cutter and stacker.

Downstream equipment:This line is assembled lattice or spiral mould,new type calibration unit and spraying cooling bath. Advanced PLC control system and large chromatic liquid-crystal screen make the operation more convenient, having a friendly human-machine interface.

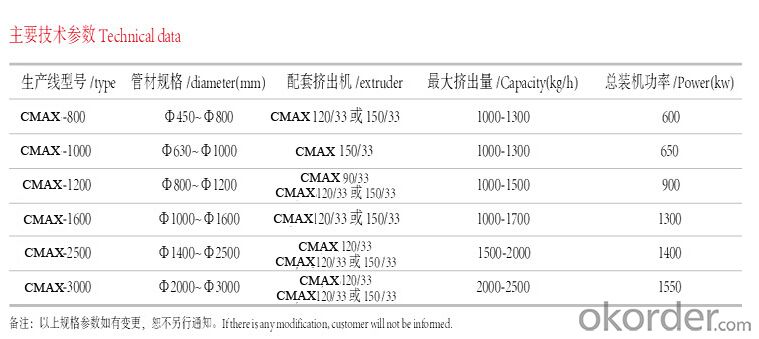

Main Technical Parameters:

Our company can design and manufacture products with different specs for clienteles.

The features:

1, We have set up one special forging team to design –develop-produce-distribute-debug-repair for our clienteles.

2, We possess strong technical power, high-tech, one complete set of checkout equipment, abundant debugging experience and timely after-sale service.

3, The most crucial is that we brave enough to innovate, keep enterprise, keep improving.

If you are interested in our product, please be free to contact us. Whether we could cooperate, we would do our best to help you. I’m confident that will be benefit to you and us!

1. The Extruder:

2.The Die Head:

3.The Vacuum Sizing Water Tank:

4.The Spraying Cooling Water Tank:

5.The Caterpillar Tractor:

6.The Cutter:

7.The Stacker:

8. The HDPE Pipe:

- Q: What is an extruder?

- Usually called extruder, it is a plastic extrusion machine.

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- The temperature setting of the extruder is related to the material you manufacture. If the type of plastic is different, the setting temperature is different, and the material of different manufacturers is also slightly different from the temperature setting. Setting the temperature completely depends on the actual situation.Generally, the position of the leaky hopper is lower than the temperature of the extruder barrel and the die head

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- In fact, if you are familiar with that extruder, there will be no problem!

- Q: why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Tensile strength is divided between longitudinal and transverse, and PE bags are transversely increased, available 8CLLDPE is added, longitudinal can be added to medium, medium density or high-density material to increase tensile strength.

Send your message to us

CMAX Large Diameter HDPE Water Supply and Gas Supply Plastic Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords