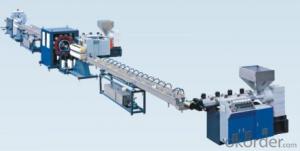

pvc wood foamed board extrusion production line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

SJZ-80 Conical Twin-Screw Extruder/twin screw plastic extruder

Screw and Barrel | 800~900HV Barrel Screw and Barrel Material 38CrMoAlA,Nitriding, Surface Chrome plate Nitriding Layer Thickness:0.5~0.7mm Surface Rigidity:800~900HV |

Screw Diameter | Φ80/156mm |

Effectual Working Length of Screw | 1800mm |

Speed of Screw | 1~37rpm |

Main Motor Power | 55KW |

Main Motor Timing Method | 55KW ABB inverter |

Force Feeder Motor Power | 0.75KW |

Force Feeder Motor Timing | 0.75KW ABB inverter |

| Barrel Heating Method | Foundry Aluminum Heater, include force cooling fan, |

| Barrel Heating Power | 24KW |

| Capacity | 250~380kg/h |

| Main Electrical Equipment | Japanese OMRON Temperature Control Meter,Siemens Contactor, Shanghai TAYEE Button and Indicator Light, Suzhou ChuangShuan digital display meter |

Conical twin screw plastic extruder:

Features Specifications:

1. Model SJZ series conical twin screw extruder is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produce all sorts of PVC plastic pipe, profile, plate material, sheet material, bar material and granulation.

2. The conical twin screws have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. The conical twin screw extruder system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plasticity performance and material quality.

4. The conical twin screw is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear larger extruding pressure.

6. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1degree.

All SJZ Series Conical Twin-Screw Extruder Technical Parameter:

Model | SJZ-51 | SJZ-55 | SJZ-65 | SJZ-80 | SJZ-92 |

| Screw Dia.(mm) | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

Max. Rotating speed(rpm) | 40 | 38 | 38 | 37 | 36 |

| Main Motor(kw) | 18.5 | 22 | 37 | 55 | 90 |

Capacity(kg/h) | 80~100 | 100~150 | 150~250 | 250~380 | 380~700 |

| Center height(mm) | 1050 | 1050 | 1050 | 1050 | 1100 |

| Net Weight(kg) | 3000 | 3500 | 4000 | 5500 | 8000 |

| L*W*H | 3.6*1.1*2.1 | 3.6*1.1*1.2 | 4.2*1.5*2.4 | 4.7*1.5*2.4 | 6*1.6*2.5 |

Plastic Pipe Extruder/Plastic Extruders:

Different types of extruders With different sorts of molds and auxiliary machines,

it can produce all sorts of PVC plastic pipe material, profiled material, plate material, sliced material, bar material and granulation.

It can also extrude PP.PE pipe at high speed by changing special barrel.

Computer control or conventional control is optional.

According to customer's requirements, most reasonable screw can be made so as to achieve best plasticity state and material quality.

The screw is made by high precision special digital screw miller; extruding property can be highly harmonized.

It has firstly introduced advanced technique of producing screws with variable pitch and depth, so that the material can be more softly sheared and cut.

The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged.

It can bear larger extruding pressure.

- Q: Basic parameters of extruder screw

- 3, compression ratio epsilon, also known as the geometric compression ratio of screw, is the ratio of the volume of the first screw groove to the volume of the last screw groove at the homogenization section. It is determined by the physical compression ratio of plastics - that is, the density of the product and the density of the performance of the feed. The extruder is relatively compressed, the purpose is to make granular plastics fully plasticized and compacted. The selection of compression ratio should be different when different kinds of processing plastics are used. According to the compression ratio, the types of screw can be divided into three types: equidistant, unequal depth, equal depth, unequal distance, unequal depth, unequal distance. Among them, equidistant and unequal depth is the most common one. This kind of screw is easy to process, the contact area of plastic and cylinder is large, and the effect of heat transfer is good.

- Q: extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Is the place where the material is easy to burn rough? Add stabilizers and lubricants appropriately. Or the outer lubrication part of low molecular weight is replaced by macromolecule lubrication

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine idealIf it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc.

- Q: PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- I can help you with this design.Select the topic according to the academic direction. The key to the value of thesis writing lies in the ability to solve specific problems in a particular industry, especially in academic terms. Therefore, one of the techniques for selecting and refining titles is to select and refine them according to their academic value.

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

- Q: What should be paid attention to in the daily maintenance of the extruder?

- HostCheck the patency of cooling water, temperature (general / 26 C), feeding, cylinder temperature and pressure, friction condition of screw and barrel.NoseThe size loss of the perforated plate, the damage and corrosion of the runner surface, and whether the obstruction occurs affect the appearance and output of the product.

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q: Now I want to do it How to change the equipment, please help tell your heroes ah!Used to do PVC pinch plate, now changed to PVC threading tube

- Do the plate equipment and pipe threading with PVC equipment, from the process, are PVC extrusion machinery, however, do different products, screw inside or something different, if you want to do product grade requirements is not high, can change, but stability is not so good ensure product.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- 1, extrusion methodAccording to plasticizing methods: dry extrusion and wet extrusionPress the way: continuous extrusion and intermittent extrusion2, characteristicsContinuous production, high efficiency, simple operation, wide range of applications [Edit] paragraph extrusion molding equipment 1, the hostExtrusion system: composed of screw and barrel, it is the key part of extruder. Its function is to melt plastics, quantitative, constant pressure, constant temperature extrusion of meltDrive system: drive the screw to increase the required torque and torqueHeating and cooling system: guarantee the temperature of plastic and extrusion system in molding process2 auxiliariesIt is composed of head, setting device, cooling device, traction device, coiling device and cutting3 、 control systemIt consists of electric apparatus, instrument and actuating mechanismPurpose: to control the main and auxiliary motor, in order to meet the demands of speed and power; control main engine temperature and pressure and flow, to ensure product quality; to achieve automatic control of the extrusion unit, ensure the coordinated operation of main and auxiliary equipment. [edit this paragraph] extruder extruder overview of plastic extruder is the host, it consists of extrusion system, transmission system and the heating and cooling system.

Send your message to us

pvc wood foamed board extrusion production line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords