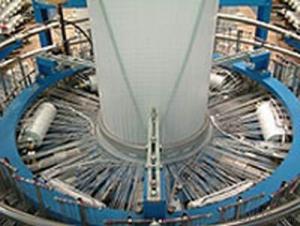

Geocells Suppliers - Circular Knitting Machine for Making Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 5 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

18-feeder computerized artificial fur plain color circular knitting machine can knit the fur&cotton sliver with high quality.

MS18-A 18-feeder computerized artificail fur plain color circular knitting machine can knit the fur&cotton sliver with high quality.

Main specifications and technical features of the MS18-A 18-feeder computerized artificial fur plain color circular knitting machine:

1. With complete up-to-date computer-controlled system, the state of working equipment, automatic fault diagnosis, automatic alarm or other related records could be displayed on the screen.

2. New added technology of broken needle detector improves the quality of jacquard knitting effectively.

3. The head of comb is designed to be more reasonable while the feeding speed and quantity is controlled more effectively, which make it adjustable according to the differences of fabric material, widening its practical scope.

4. The design of adjustable tile can keep those rotating parts such as cylinders working in their best condition and rotating more smoothly and steadily. It can be much easier and more convenient to maintain the machines.

5. Cloth roller adapts magnetic-pull-control system, being the most advanced in the world. It is able to adjust the pull force according to requests, improving the fur weaving quality.

6. Both of ‘Uphil’ angle and ‘Downhil’ angle use advanced “A” and ”B” blocks in order to make working parts such as needle and sinker work with more accuracy and coordination. It is possible to make it a reality to freely change the blocks in the same places with similar blocks.

7. New improved density adjusting equipment provides convenience and accuracy to adjust density of every route, which makes it easy to adjust the machine and simple to operate.

8. The storage of cloth is increased, making it more suitable for production.

9. This product features the advantages of imported machines as respect to appearance and structure and may compare favorably with imported machines.

Cylinder Diameter | 24’’/610mm 27’’/686mm |

Cylinder Grade | E14/1056(24’’) E12/1056(27’’) E14/1176(27’’) |

Feeds Routes | 18 |

Cylinder Speed | 40r/min |

Main Motor Power | 7.5kw |

Weaving Needles Model | 88.82 |

Installation Size(LWH) | 3325mm,2510mm,3425mm |

Woven Geotextiles Data Sheet

Item | Testing Method | Unit | ||

Grad Tensile Strength | ASTM-D 4632 | N | 890 | 1405 |

Grab Elongation | ASTM-D 4632 | % | ≤20 | ≤20 |

Puncture Strength | ASTM-D 4833 | N | 400 | 667 |

CBR Puncture | ASTM-D 6241 | N | 3200 | 4800 |

Mullen Burst | ASTM-D 3786 | kPA | 2578 | 4137 |

Trapezoidal Tear | ASTM-D 4533 | N | 500 | 750 |

Apparent Opening Size | ASTM-D 4751 | mm | 0.425 | 0.425 |

Permittivity | ASTM-D 4491 | Sec-1 | 0.05 | 0.05 |

Water Flow Rate | ASTM-D 4491 | 1/m/m2 | 163 | 163 |

UV Resistance | ASTM-D 4355 | % 500hrs | 70 | 70 |

Roll Width | m | 6 | 6 | |

Roll Length | m |

100 | 100 | |

Mass | GSM | 200 | 300

|

- Q: Can geogrids be used in green roof systems?

- Yes, geogrids can be used in green roof systems. They provide reinforcement to the roof structure and help to distribute the load of the green roof materials. Geogrids also aid in preventing soil erosion and provide stability to the vegetation and growing medium on the roof.

- Q: What are the factors that affect the cost-effectiveness of geogrids?

- The key factors that affect the cost-effectiveness of geogrids include the quality and durability of the geogrid material, the specific application and site conditions, the installation process, and the overall project requirements and goals. Additionally, factors such as the availability and accessibility of geogrids, the cost of transportation, and any necessary maintenance or repair costs also contribute to the cost-effectiveness.

- Q: Are geogrids resistant to high temperatures?

- Yes, geogrids are generally resistant to high temperatures. They are designed to withstand extreme temperature conditions and maintain their structural integrity.

- Q: How to choose 15kn bidirectional geogrid geogrid

- First of all, in the choice of geogrid types, according to the construction project categories selected, according to the environmental impact of the project in which the same project many times in different environments with different types of grid.

- Q: Do you need a production license for the production of geogrid?

- If you need to sell to mine coal card

- Q: How many square meters of steel plastic geogrid inspection

- Under normal circumstances, the detection of steel plastic geogrid is 10 thousand square meters. The specific quantity shall be subject to the supervision personnel.

- Q: What are the applications of geogrids?

- Geogrids have various applications in civil engineering and construction projects. They are commonly used for soil stabilization, reinforcement of retaining walls and slopes, erosion control, and pavement reinforcement. Geogrids provide strength and stability to the soil, prevent soil movement, and improve the overall structural integrity of the project.

- Q: How do geogrids enhance the stability of steep railway embankments?

- Geogrids enhance the stability of steep railway embankments by providing reinforcement and preventing soil erosion. They are placed within the soil layers, creating a strong interlocking system that distributes the applied loads and increases the overall strength of the embankment. This helps to prevent slope failures, maintain the embankment's shape, and improve its resistance to lateral movements and settlement. Geogrids also promote better drainage and reduce the risk of water accumulation, which further enhances the stability of the embankment.

- Q: What are the advantages of using geogrids in ground improvement for load transfer platforms?

- Geogrids offer several advantages in ground improvement for load transfer platforms. Firstly, they enhance soil stability by reinforcing the ground, thereby increasing its load-bearing capacity. This allows for the construction of larger and more robust load transfer platforms, capable of supporting heavy loads. Additionally, geogrids help to distribute the load more evenly across the platform, reducing the risk of localized failures or settlements. Moreover, these geosynthetic materials are durable and resistant to degradation, ensuring the longevity and effectiveness of the ground improvement solution. Overall, geogrids provide a cost-effective and efficient method for strengthening and stabilizing the soil, resulting in improved performance and safety of load transfer platforms.

- Q: How to do this in the geogrid in the retaining wall? Is there any remedy?

- No long-term creep as reinforcing material, have in long-term load under the condition of deformation resistance that the creep resistance is extremely important, glass fiber does not creep, which ensure product can maintain long-term performance.

Send your message to us

Geocells Suppliers - Circular Knitting Machine for Making Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 5 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords