China Supplier Selling Gypsum Drywall Partition Metal Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

China Supplier Selling Gypsum Drywall Partition Metal Track

Customized specifications are available

----all kinds of channels, galvanized t-bars, accessories

----related products (boards and ceilings)

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield

strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health

and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a

selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud

every 600mm, which is easy for workers to install the electric lines and water tubes.

3.Image

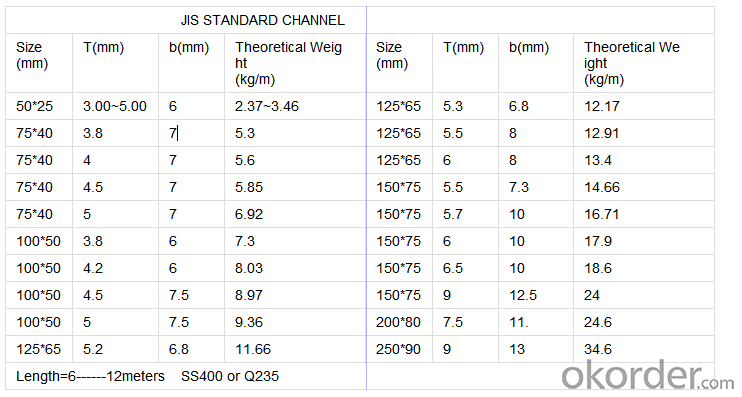

4.Detailed Specification

5.FAQ

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

- Q: In Shanghai 75 partition wall light steel keel 0.6 what price now

- What brand to see it? Four brands are more expensive. Generally in the 7.5-9.5 a meter In the high-end 4.5-6.5 yuan / m

- Q: Light steel keel wall to withstand the number of wind load

- This test really no standard, the general wall is not the index of wind pressure, mechanics is also the most test is the impact and static load test, personal feeling according to the thickness of the keel, the height of the wall, supporting the keel, supporting card Whether it is complete, wall pressure against the wind is almost 200 ~ 600Pa no obvious deformation.

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- My family on the 85-year house, a lot of people in the district to do solid wood flooring, also used very good, no see who said their own floor problems. Did you knock on the wall? 24 walls are load-bearing, you can not knock, even if you want to knock, but also I-beam or channel support, the longer the wall, just the more important specifications, we are all of these houses are prefabricated panels, Direction, take the wall is absolutely can not knock, there will be a lot of dangerous risks.

- Q: Light steel keel should be how to strengthen, in order to make solid wood door installed more prison?

- Light steel keel wall strength regardless of Zeyang are a heart disease, if there is room, then the proposal is still good wall

- Q: Light steel keel gypsum board wall height is how to determine

- There is no specific rigid provisions, the specific height according to the actual situation to the scene. Light steel wall commonly used for each root is 3 meters long, if the actual height beyond too much, you can order.

- Q: Can my light steel keel ceiling withstand the weight?

- To be honest, the thickness of light steel is not visible, and even your different specifications are difficult to identify together. If the figure shown on the release of these things did not occur under the deformation of light steel, it should be no problem

- Q: To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With C-beam or two angle steel, LI put two and wall fixed, the keel fixed to the LI. Do not be able to drill on the ground.

- Q: How to remove the gypsum board cut off

- Before the demolition, look at the original decoration construction drawings, or consult the owners, understand the distribution of water and electricity, wall decoration materials, cut off size and so on. If the partition inside there are hydropower, first the total valve or related valve closed to remove the partition. If the decoration materials are tiles and the like, pay attention to the ground to do protection, so as not to drop the ground tiles. To see whether the wall is anti-magnetic or wall whether there is sound insulation material, if any, must be done before the demolition of the relevant anti-magnetic or noise protection measures to avoid demolition later less than remedial loss. If the larger size of the partition is necessary, the first partition wall to do the guardrail, or playing keel, as a fixed wall, and then split.

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- Can, to the dragon it to use a little bit of the screw, but look at your floor is still in the cement or above the floor to do in the cement above with a drill to pull the explosion can be a With a long screw, If it is done on the floor of the board it, It is recommended to use a little bit of the screw to play on the above plus gasket To do about the foot line, and the floor color, only to coordinate points

- Q: How to construct double - sided double gypsum board partition wall

- Line: according to the design and construction plans, in accordance with the keel width of the elastic line, has been done on the ground or ridge to release the wall position line, door and window openings border line, and put the top, wall keel position edge. To cover the panel of the long, wide sub-file, to ensure that the keel position is correct. Heaven and earth keel installation, along the ball line fixed top, to keel, fixed point spacing should not be greater than 600mm, keel docking should remain straight. Fixed keel keel, keel the end should be fixed, fixed should be solid. Wall, column edge keel with nails or wood screws and walls, column fixed, nail distance of 1000mm.

Send your message to us

China Supplier Selling Gypsum Drywall Partition Metal Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords