Drywall Metal Studs and Tracks Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

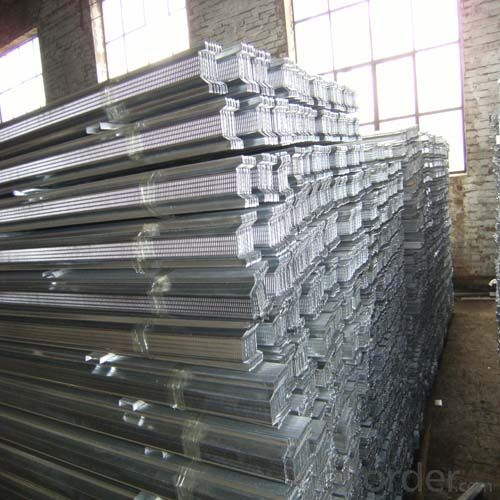

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

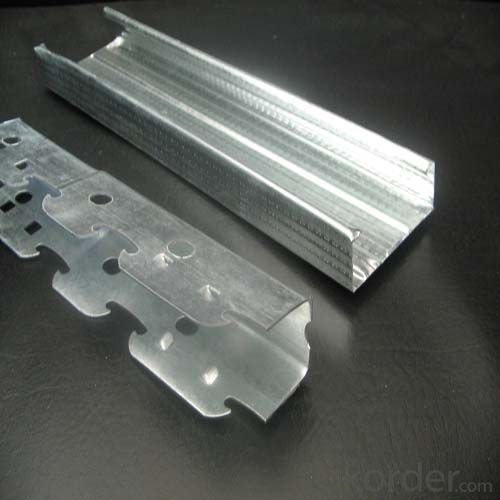

C metal stud is faced with plasterboard

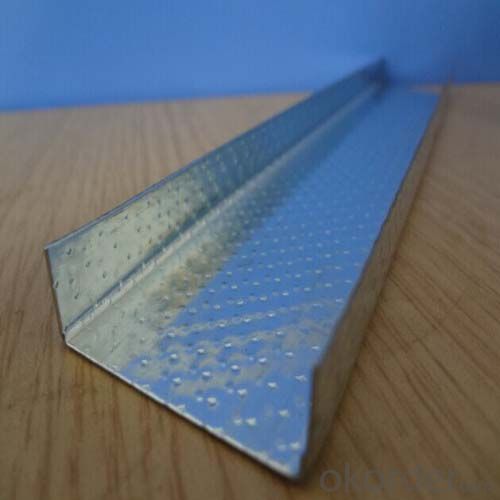

U metal track is installed along the floor to fix metal stud

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Light steel keel wall to withstand the number of wind load

- Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on.

- Q: Light steel keel partition wall fire retardant coating shabu several surface

- Grass-roots side of the wooden side need to brush four sides, the base liner is two sides, but the paste surface layer of decorative panels generally just brush a back, the front is usually not brush fire paint, or should be the quality of surface layer decorative plate paste.

- Q: Light steel keel wall Why use gypsum board to do grass-roots level?

- It is not necessary to use gypsum board but gypsum board there are many other materials can not replace the advantages of easy paint on the paint, such as latex is also its weight is more suitable for the keel does not have too much pressure on the pressure there are other advantages One by one in detail the gypsum board used in light steel keel partition is a good choice.

- Q: Light steel keel wall waterproof

- The grass on the surface of the gray skin with a knife to remove, with a broom to dust, sand and other debris clean, especially the root, floor drain and drain and other parts to be carefully cleaned. If there is oil, apply wire brush and sandpaper brush off. The base surface must be flat, the depression should be filled with cement putty.

- Q: Is it possible to use a hollow brick or a 95 brick?

- Decoration in the practice of a lot of walls, in addition to brick, you can also use light steel keel plus gypsum board practice and so on, the key is to look at the area of the wall surrounded by how much, in what position, use, etc., then To decide the wall of the program.

- Q: To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With a lightweight partition, brick, and do not do gypsum board wall.

- Q: 100 square light steel keel wall how many pieces of heaven and earth keel

- It depends on how high you need to partition the wall, if it is separated by 2 meters high wall, then up and down the world keel each need 50 meters. , If it is separated by 4 meters high wall, up and down the world keel each need 25 meters.

- Q: Light steel keel gypsum board partition wall brush black latex paint, I would like to change the brush blue latex paint, how to deal with grassroots?

- First with glue all roller brush again, and then approved once again talcum putty (as in the north with a double powder, that is, "white"), sand polish after leveling, you can roll the new latex paint. There is a need for a patch on the wall, just at the same time.

- Q: 9 + 9 double gypsum board is what it means

- Is the two layers of 9mm gypsum board superimposed practice (in fact, the standard thickness of the gypsum board should be 9.5mm), which in the light steel keel wall design, is more common. It is more than a single layer of gypsum board in the crack to avoid the problem, to be much more insurance.

- Q: How much does it cost to use a light steel keel gypsum board?

- 800 yuan to 1,000 yuan, which is the cost of the price If it is the company to do you probably about 1800-2,200 yuan.

Send your message to us

Drywall Metal Studs and Tracks Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords